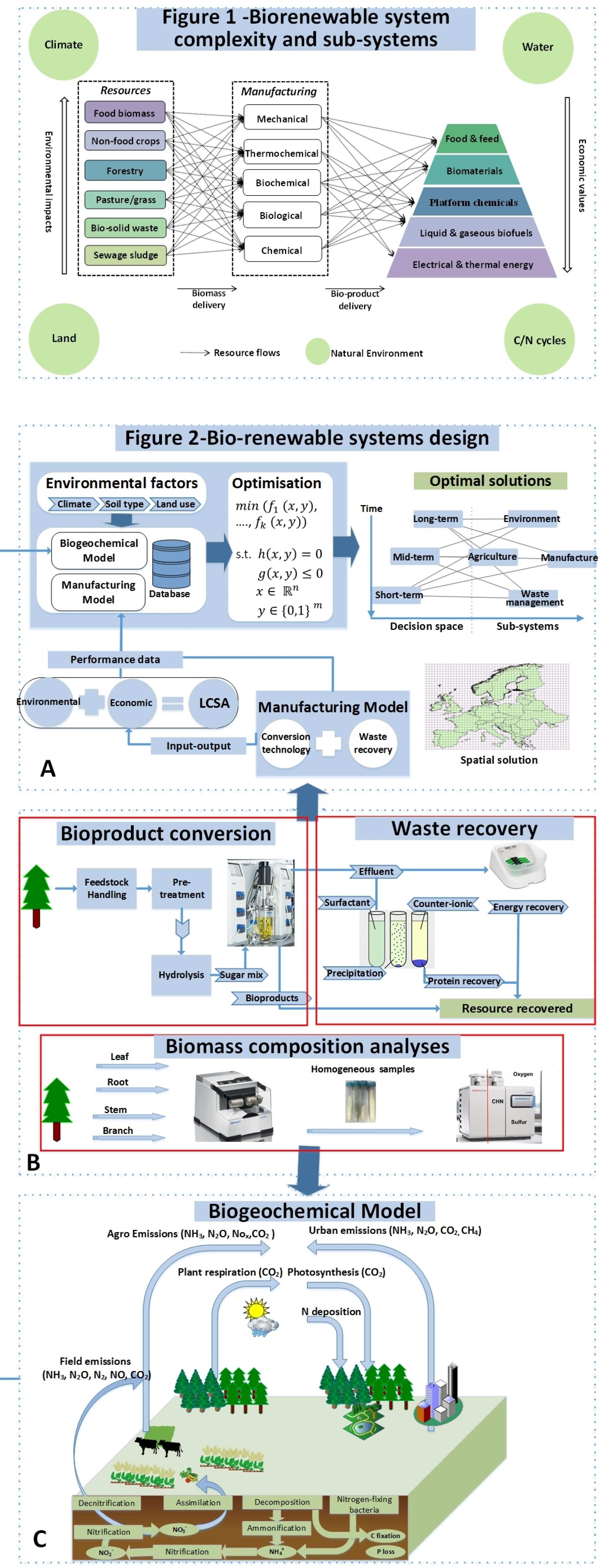

Background: Driven by environmental challenges, a transition from fossil-based to a bio-economy is evolving progressively. The bio-economy is underpinned by the production of biological resources (biomass) and the conversion of these resources and waste into bio-products (i.e. biorenewable), including bio-energy, biochemical, bioplastics, feed, which are often co-produced. However, the translation of fundamental research into sustainable solutions across the energy and biorenewable sectors is hindered by the system complexity and fragmented sub-systems (Fig-1). The system complexity spans from interconnection between resources, manufacturing and environmental factors to the conflict between sustainability criteria. Biorenewable sub-systems include natural environment, agriculture, manufacturing and waste management. These subsystems are underpinned by carbon and nitrogen (C/N) cycles including the plant-land-climate biogeochemical cycles, and biomass molecules conversion into biorenewables. Despite the Science-Engineering advances, major challenges on how to tackle system complexity and achieve sustainable design across biorenewable sub-systems still remain.

Research Development: An approach has been developed to incorporate the technology development within an overarching modelling framework (Fig-2A) that integrates the fragmented sub-systems. This research integrates several components -

- Empirical work (Fig-2B) includes biomass compositional analyses and closed-loop biorenewable conversion from biomass/waste;

- An validated biogeochemical model (Fig-2C) simulates the C/N transport and transformation across plant-soil-climate and computes biomass growth;

- Manufacturing simulation model and life cycle sustainability assessment (LCSA) quantify the techno-economic and environmental performances;

- Mathematical modelling (Fig-2A) integrates the biogeochemical and manufacturing simulation, LCSA, and empirical data with multi-objective optimisation. Multi-objective optimisation accounts for spatial-temporal decision spaces and optimises economic and environmental performances across sub-systems.

Collaborating with industrial pioneers, the capability of this approach has been tested in bio-renewable applications, ranging from manufacturing to supply chain design.

Contact us

Miao Guo, Principal Investigator and EPSRC Research Fellow,

Department of Chemical Engineering,

Imperial College London, South Kensington Campus

London

SW7 2AZ

Email: miao.guo@imperial.ac.uk

Telephone: +44 (0) 20 7594 3379