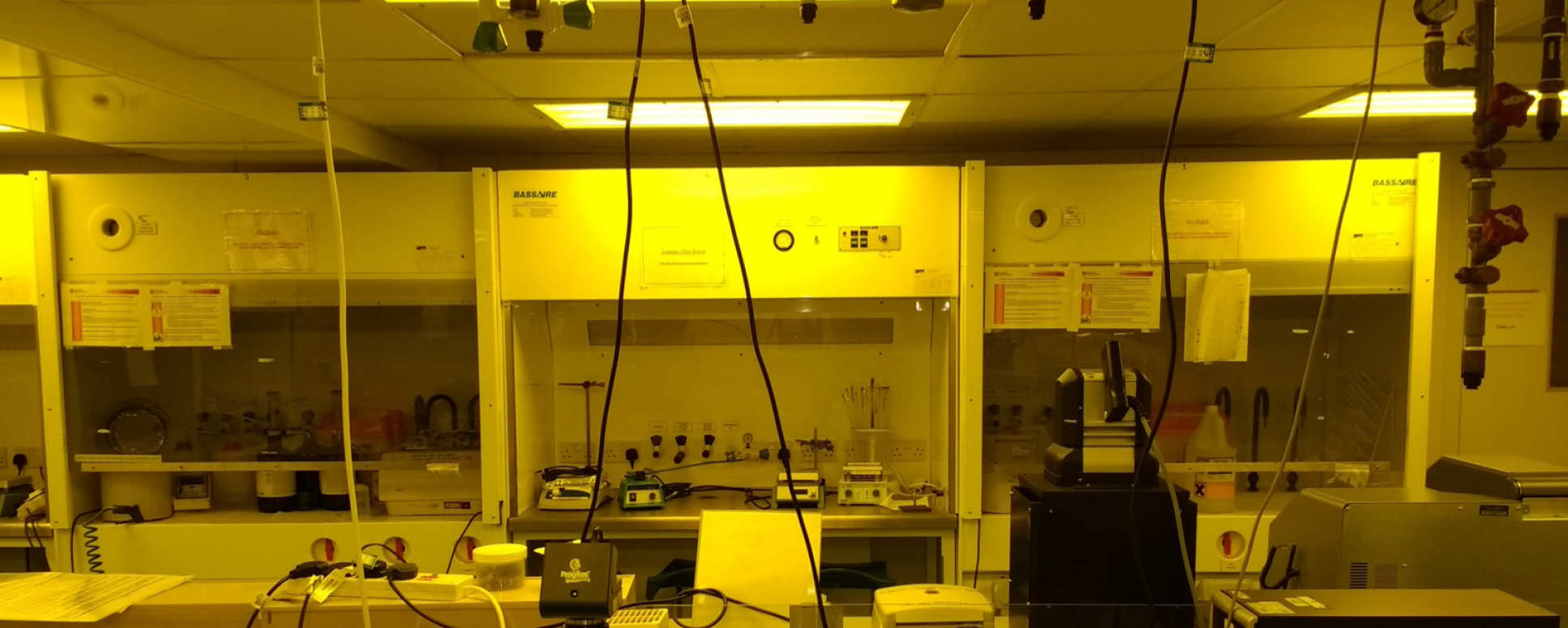

Cleanroom

The Experimental Solid State Physics group operates a 50m2 cleanroom located in the Blackett building. It is a class 1000 environnement, meaning that less than a thousand 0.5 micron particles can be found per cubic foot. It is used in semiconductor, polymer and nanotechnology processing, and welcomes more than 50 users, EXSS research staff, as well as MSci students and external visitors.

Contacts

The cleanroom is managed by the cleanroom committee:

Cleanroom PI: Ji-Seon Kim

Cleanroom Manager: David Mack

Members:

Cleanroom landline: 0207-594-7707

Please do not hesitate to contact any of us for further information concerning the cleanroom, or to report incidents/accidents/safety issues within the cleanroom.

How to obtain cleanroom access?

In order to register for cleanroom access, please contact David Mack. You will need to attend an induction with the cleanroom manager and be assigned a 'cleanroom mentor'.

Short term visitors and undergraduate students are allowed access to the cleanroom provided they are accompanied by a cleanroom user who is a member of staff, or a Postdoctoral Researcher (NOT a student). Please contact the cleanroom manager in time for a proper induction briefing (David Mack).

Safety in the cleanroom

The cleanroom is for the sole purpose of performing semiconductor, polymer and nanotechnology processing. The work quality and safety of everybody depends on how well each user has understood the safety issues present in the cleanroom.

If someone needs to work over the weekends, Bank holidays and College holiday closures in the cleanroom; they must be a senior user and provide an Extended hours access form signed by the supervisor to David Mack or Stephen Cussell.

Keeping the cleanroom clean

Cleanrooms have to be kept clean to work. Each week one user is responsable for cleaning duty. All users are always responsable for keeping the cleanroom in good condition in the first place.

→ Check what the cleaning duty involves: Cleaning Duty Instructions

Equipment & common procedures manuals

A general Code of Practice has been elaborated by and for cleanroom users. It contains useful information regarding general usage rules of the cleanroom, detailed safety procedures, descriptions of the most common cleanroom procedures, and a lot of common chemicals found in the cleanroom.

Please make sure you and your visitors have read through it: Cleanroom COP

The cleanroom equipment reflects the versatility of the research done in the EXSS group, ranging from the fabrication of nanosized magnets to organic solar cell processing.

Techniques and Equipment Available:

| Profiling surfaces |

|

| Metal deposition |

|

| Optical analysis |

|

| Spectral analysis |

|

| Patterning |

|

| General sample preparation |

|

Some common procedures performed in the cleamroom:

- Soft lithography

- Etching Plastic Substrates

- Organic Semiconductor Solution Preparation

- Photolithography and Photoresist Processing

- Cleaning ITO samples

- PEDOT:PSS deposition

Nanofabrication Laboratory

The nanofabrication laboritory is focused on nano and micro fabrication patterend using electron beam lithography and direct writing photolithography. Thin film deposition is done using physical vapor deposition techniques.

Current fabrication Activities:

InSb/AllnSb quantum well nanodievices and Hall probes, InAs/AlSB quantum well nanodevices, nanoplasmonic antennas/arrays, planar spin-ice structures, graphene devices, microfluidics devices.

Nanofabrication Laboratory Contacts

Nanofabrication Laboratory Contacts

Cleanroom PIs: Will Branford & Lesley Cohen

Laboratory Manager: David Mack

Techniques and Equipment Available:

| Deposition |

|

| Optical analysis |

|

| Patterning |

|

| General sample preparation |

|

Facility contacts

- Email Ji-Seon Kim (Professor of Solid State Physics and Director of the Plastic Electronics Center for Doctoral Training)

- Email David Mack (Nanofabrication Technician)