Scientists collaborate on project to make next generation industrial filters

by Colin Smith

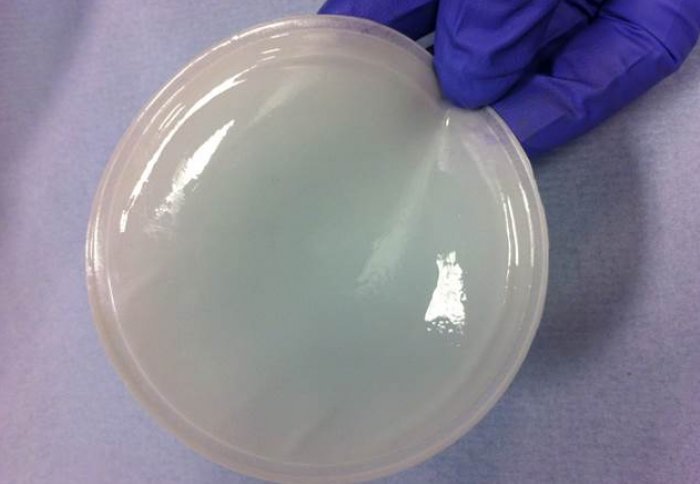

Membrane technology made from plastics

Making industrial filtration technology more efficient and sustainable is the focus of a new academic partnership involving Imperial College London.

More than 15 per cent of energy generated globally is used to separate substances - from sewerage treatment to the production of pharmaceuticals and the refining of oil and gas. The membrane technology used to separate these substances is currently limited, often made from materials that are short lived, energy intensive to use, costly to make and requiring regular replacement

We believe that the membranes we are developing could lead to more stable performance in many industries, ultimately making them more sustainable.

– Professor Andrew Livingston

Head of the Department of Chemical Engineering

Imperial College London and the Universities of Bath, Manchester and Newcastle have created a new collaboration called SynFabFun, announced this month, to explore the potential of new materials to improve existing membrane systems currently used by industry.

In one of the SynFabFun projects, Imperial will lead on a £1.5 million research initiative to investigate the use of new types of polymers and ceramics for use in membrane technology. One of the challenges with conventional membranes is that they become less porous over time, slowing the flow of filtered liquid, leading to higher energy consumption in the filtration process and eventual replacement of the membrane. The team will be experimenting with ceramics and polymers that are more porous at the nanoscale level, making them more able to filter substances over longer periods.

Professor Andrew Livingston and Professor Kang Li, both from the Department of Chemical Engineering at Imperial, will lead on the College’s research programme.

Professor Livingston said: “Membrane technologies are the unseen workhorse in many industrial processes. Our modern societies use membranes to refine anything from water to oil and yet the underlying structures of these membranes have largely been unchanged for decades, leading to inefficiencies. We believe that the membranes we are developing could lead to more stable performance in many industries, ultimately making them more sustainable.”

He is the founder of the an Imperial spinout company, Evonik Membrane Extraction Technology, recently acquired by Evonik Industries, which develops membranes that filter organic solvents that are used in a range of industrial processes.

SynFabFun is funded by the Engineering and Physical Sciences Research Council.

Members of the public can learn more about membrane technology at the Imperial Festival, which showcases the best in science and arts. Dr Angela Lonergan, from the Department of Chemical Engineering, will be on hand at the water cycle demonstration to discuss with festival goers the efficiency of membrane technology versus heat evaporation processes used in water filtration.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Colin Smith

Communications and Public Affairs