Overview

Billy's research is broadly broken down into 2 main themes: energy and manufacturing.

Within energy, his research activities are at the interface between fundamental science and engineering application of electrochemical energy storage and conversion devices. Active topics include: lithium-ion batteries, supercapacitors, fuel cells, metal-air batteries and redox flow batteries with cross cutting topics including development of new electrodes, continuum level modelling, understanding degradation, thermal management, pack/stack designs and control.

Within manufacturing, most of his work focuses on additive manufacturing, specifically direct metal laser sintering and electrochemical 3D printing, but with interests in manufacturing techniques such as nanofibre electrospinning.

Check out our group website: Electrochemical Science and Engineering which is in partnership with Design Engineering, Mechanical Engineering, Earth Science and Engineering and Chemical Engineering.

A list of all of Billy's papers can be found on his Google scholar page.

Batteries

Lithium-ion batteries are the technology of choice for consumer electronics, electric vehicles and grid scale energy storage. However, limitations with lifetime and energy density hinder their more widespread use. My research areas include:

- Physics based modelling and model based control systems

- Battery characterisation

- Diagnostic techniques for condition monitoring

- Battery pack and thermal management systems

- Understanding and quantifying degradation

Featured research

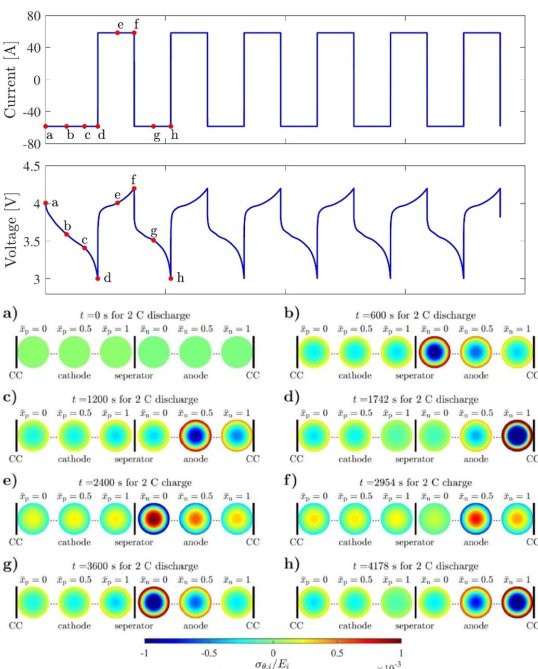

When batteries are cycled the active material expands and contracts. Consequentially, the stresses generated can lead to particle fracture and capacity fade. Here we have developed a physics based model which quantifies the stresses generated in the battery electrodes which can be used as a control metric to avoid mechanical degradation.

Electrochemical thermal-mechanical modelling of stress inhomogeneity in lithium-ion pouch cells. Weilong Ai et al. Journal of the Electrochemical Society. 2020.

Selected publications:

Degradation in parallel-connected lithium-ion battery packs under thermal gradients. Max Naylor Marlow, Jingyi Chen, Billy Wu. Communications Engineering. 2024

Enabling battery digital twins at the industrial scale. Matthieu Dubarry, David Howey, Billy Wu. Joule. 2023

A coupled phase field formulation for modelling fatigue cracking in lithium-ion battery electrode particles. Weilong Ai, Billy Wu, Emilio Martínez-Pañeda. Journal of Power Sources. 2022

Generalised diagnostic framework for rapid battery degradation quantification with deep learning. Haijun Ruan, Jingyi Chen, Weilong Ai, Billy Wu. Energy & AI. 2022.

A composite electrode model for lithium-ion batteries with silicon/graphite negative electrodes. Weilong Ai, Niall Kirkaldy, Yang Jiang, Gregory Offer, Huizhi Wang and Billy Wu. Journal of Power Sources. 2022.

Immersion cooling for lithium-ion batteries - A review. Charlotte Roe, Xuning Feng, Gavin White, Ruihe Li, Huaibin Wang, Xinyu Rui, Cheng Li, Feng Zhang, Volker Null, Michael Parkes, Yatish Patel, Yan Wang, Hewu Wang, Minggao Ouyang, Gregory Offer, Billy Wu. Journal of Power Sources. 2022

Meta-analysis of experimental results for heat capacity and thermal conductivity in lithium-ion batteries: A critical review. Marco Steinhardt, Jorge Varela Barreras, Haijun Ruan, Billy Wu, Gregory Offer and Andreas Jossen. Journal of Power Sources. 2022.

Interactions are important: Linking multi-physics mechanisms to the performance and degradation of solid-state batteries. Mei-chin Pang, Kai Yang, Rowena Brugge, Teng Zhang, Xinhua Liu, Feng Pan, Shichun Yang, Ainara Aguadero, Billy Wu, Monica Marinescu, Huizhi Wang, Gregory Offer. Materials Today. 2021

Lithium Ion Battery Degradation: What you need to know. Jacqueline Sophie Edge, Simon O'Kane, Ryan Prosser, Niall Kirkaldy, Alastair Patel, Anisha, Hales, Abir Ghosh, Weilong Ai, Jingyi Chen, Jason Jiang, Shen Li, Mei-Chin Pang, Laura Bravo Diaz, Anna Tomaszewska, Waseem Marzook, Karthik Radhakrishnan, Huizhi Wang, Yatish Patel, Billy Wu, Gregory Offer. Physical Chemistry Chemical Physics. 2021

Battery degradation-aware current derating: An effective method to prolong lifetime and ease thermal management. Michael Schimpe, Jorge Varela Barreras, Billy Wu, Gregory Offer. Journal of the Electrochemical Society. 2021

Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Billy Wu, W Dhammika Widanage, Shichun Yang, Xinhua Liu. Energy & AI. 2020.

Designer uniform Li plating/stripping through lithium-cobalt alloying hierarchical scaffolds for scalable high-performance lithium-metal anodes. Xinhua Liu, Xiaojuan Qian, Weiqiang Tang, Hiu Luo, Yan Zhao, Rui Tan, Mo Qiao, Xinlei Gao, Yang Hua, Huizhi Wang, Shuangliang Zhao, Chao Lai, Magda Titirici, Nigel Brandon, Shichun Yang, Billy Wu. Journal of Energy Chemistry. 2020.

Revealing the anion intercalation behavior and surface evolution of graphite in dual-ion batteries via in situ AFM. Kai Yang, Langlang Jia, Xinhua Liu, Zijian Wang, Yan Wang, Yiwei Li, Haibiao Chen, Billy Wu, Luyi Yang and Feng Pan. Nano Research. 2020

Novel inorganic composite materials for lithium-ion batteries. Xinhua Liu, Chandramohan George, Huizhi Wang and Billy Wu. Encyclopedia of inorganic and bioinorganic chemistry. 2019

Electrochemical thermal-mechanical modelling of stress inhomogeneity in lithium-ion pouch cells. Weilong Ai, Ludwig Kraft, Johannes Sturm, Andreas Jossen and Billy Wu. Journal of the Electrochemical Society. 2020.

Lithium-ion battery fast charging: A review. Anna Tomaszewska, Zhengyu Chu, Xuning Feng, Simon O'Kane, Xinhua Liu, Jingyi Chen, Chenzhen Ji, Elizabeth Endler, Ruihe Li, Lishuo Liu, Yalun Li, Siqi Zheng, Sebastian Vetterlein, Ming Gao, Jiuyu Du, Michael Parkes, Minggao Ouyang, Monica Marinescu, Gregory Offer and Billy Wu. eTransportation. 2019

The effect of cell-to-cell variations and thermal gradients on the performance and degradation of lithium-ion battery packs. Xinhua Liu, Weilong Ai, Max Naylor Marlow, Yatish Patel and Billy Wu. Applied Energy. 2019

Operando visualization and multi-scale tomography studies of dendrite formation and dissolution in zinc batteries. Vladimir Yufit, Farid Tariq, David Eastwood, Moshiel Biton, Billy Wu, Peter Lee and Nigel Brandon. Joule. 2018

An easy-to-parameterise physics-informed battery model and its application towards lithium-ion battery cell design, diagnosis, and degradation. Yu Merla, Billy Wu, Vladimir Yufit, Ricardo Martinez-Botas and Gregory Offer. Journal of Power Sources. 2018

Extending battery life: A low-cost practical diagnostic technique for lithium-ion batteries. Yu Merla, Billy Wu, Vladimir Yufit, Nigel Brandon, Ricardo Martinez-Botas and Gregory Offer. Journal of Power Sources. 2016

Novel application of differential thermal voltammetry as an in-depth state-of-health diagnosis method for lithium-ion batteries. Yu Merla, Billy Wu, Vladimir Yufit, Nigel Brandon, Ricardo Martinez-Botas and Gregory Offer. Journal of Power Sources. 2016

An integrated approach for the analysis and control of grid connected energy storage systems. Charalampos Patsios, Billy Wu, Efstratios Chatzinikolaou, Daniel Rogers, Neal Wade, Nigel Brandon and Phil Taylor. Journal of Energy Storage. 2016

Differential thermal voltammetry for tracking of degradation in lithium-ion batteries. Billy Wu, Vladimir Yufit, Yu Merla, Ricardo Martinez-Botas, Nigel Brandon and Gregory Offer. Journal of Power Sources. 2014

In-Operando X-ray Tomography Study of Lithiation Induced Delamination of Si Based Anodes for Lithium-Ion Batteries. Farid Tariq, Vladimir Yufit, David S. Eastwood, Yu Merla, Moshiel Biton, Billy Wu, Zhangwei Chen, Kathrin Freedman, Gregory Offer, Emanuel Peled, Peter D. Lee, Diana Golodnitsky, and Nigel Brandon. ECS Electrochemistry Letters. 2014

Coupled thermal-electrochemical modelling of uneven heat generation in lithium-ion battery packs. Billy Wu, Vladimir Yufit, Monica Marinescu, Gregory J. Offer, Ricardo F. Martinez-Botas, Nigel P. Brandon. Journal of Power Sources. 2013

The effect of thermal gradients on the performance of lithium-ion batteries. Yannic Troxler, Billy Wu, Monica Marinescu, Vladimir Yufit, Yatish Patel, Andrew J. Marquis, Nigel P. Brandon and Gregory J. Offer. Journal of Power Sources. 2013

Supercapacitors

Electrochemical Double Layer Capacitors, or Supercapacitors, are another type of energy storage device that is being considered as a powertrain component in electric vehicles. These are characterised by their high power rate capabilities but the drawback is their limited energy density. My research activities include:

- Modelling of supercapacitors

- Pseudocapacitors

- Ionogel based electrolytes

- Electrospun nanofiber electrodes

Featured research

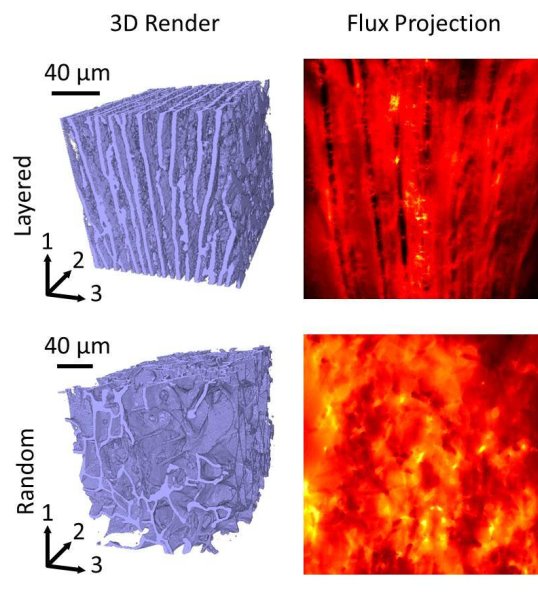

The power density of a supercapacitor is affected by the rate of ionic diffusion between its 2 electrodes. In this work we an ice templating approach to create aligned porosity in ionogel based separators for high temperature and high voltage supercapacitors to enhance rate-capability. The use of x-ray computed tomography allows us to quantify the benefits in transport properties of this manufacturing technique.

Aligned ionogel electrolytes for high-temperature supercapacitors. Xinhua Liu et al. Advanced Science. 2019

Publications:

Degradation Diagnostics for Li4Ti5O12-Based Lithium Ion Capacitors: Insights from a Physics-Based Model. Ganesh Madabattula, Billy Wu, Monica Marinescu and Gregory Offer. Journal of the Electrochemical Society. 2020

How to design lithium ion capacitors: Modelling, mass ratio of electrodes and prelithiation. Ganesh Madabattula, Billy Wu, Monica Marinescu and Gregory Offer. Journal of the Electrochemical Society. 2019

Electrospun composite nanofibre supercapacitors enhanced with electrochemical 3D printed current collectors. Xiaolong Chen, Xinhua Liu, Mengzheng Ouyang, Peter Childs, Nigel Brandon and Billy Wu. Journal of Energy Storage. 2019.

“All-in-Gel” Design for Supercapacitors towards Solid-State Energy Devices with Thermal and Mechanical Compliance. Chengyao Yin, Xinhua Liu, Junjie Wei, Rui Tan, Jie Zhou, Mengzheng Ouyang, Huizhi Wang, Samuel Cooper, Billy Wu, Chandramohan George and Qigang Wang. Journal of Materials Chemistry A. 2019.

Aligned ionogel electrolytes for high-temperature supercapacitors. Xinhua Liu, Oluwadamilola Taiwo, Chengyao Yin, Mengzhang Ouyang, Ridwanur Chowdhury, Baofeng Wang, Huizhi Wang, Billy Wu, Nigel Brandon, Qigang Wang and Samuel Cooper. Advanced Science. 2019

Nickel Cobaltite@Poly(3,4-ethylenedioxypyrrole) and carbon nanofiber interlayer based flexible supercapacitor. Sathish Deshagani, Xinhua Liu, Billy Wu and Melepurath Deepa. Nanoscale. 2019

Flexible all-fiber electrospun supercapacitor. Xinhua Liu, Max Naylor Marlow, Samuel Cooper, Bowen Song, Xiaolong Chen, Nigel Brandon and Billy Wu. Journal of Power Sources. 2018

3D-Printed Structural Pseudocapacitors. Xinhua Liu, Rhodri Jervis, Robert Maher, Ignacio Villar-Garcia, Max Naylor-Marlow, Paul Shearing, Mengzheng Ouyang, Lesley Cohen, Nigel Brandon and Billy Wu. Advanced Materials Technologies. 2016

Tough ionogel-in-mask hybrid gel electrolytes in supercapacitors with durable pressure and thermal tolerances. Xinhua Liu, Billy Wu, Nigel Brandon and Qigang Wang. Energy Technology. 2016

Fuel cells

Low temperature Proton Exchange Membrane Fuel Cells (PEMFCs) are the current fuel cell technology of choice in automotive applications. Current challenges limiting their widespread uptake include: limited lifetime, high cost and performance issues. My research activities in the PEMFC space include:

- Novel system and stack designs

- Design tools for PEMFC systems

- Diagnostic and characterisation techniques

Featured research

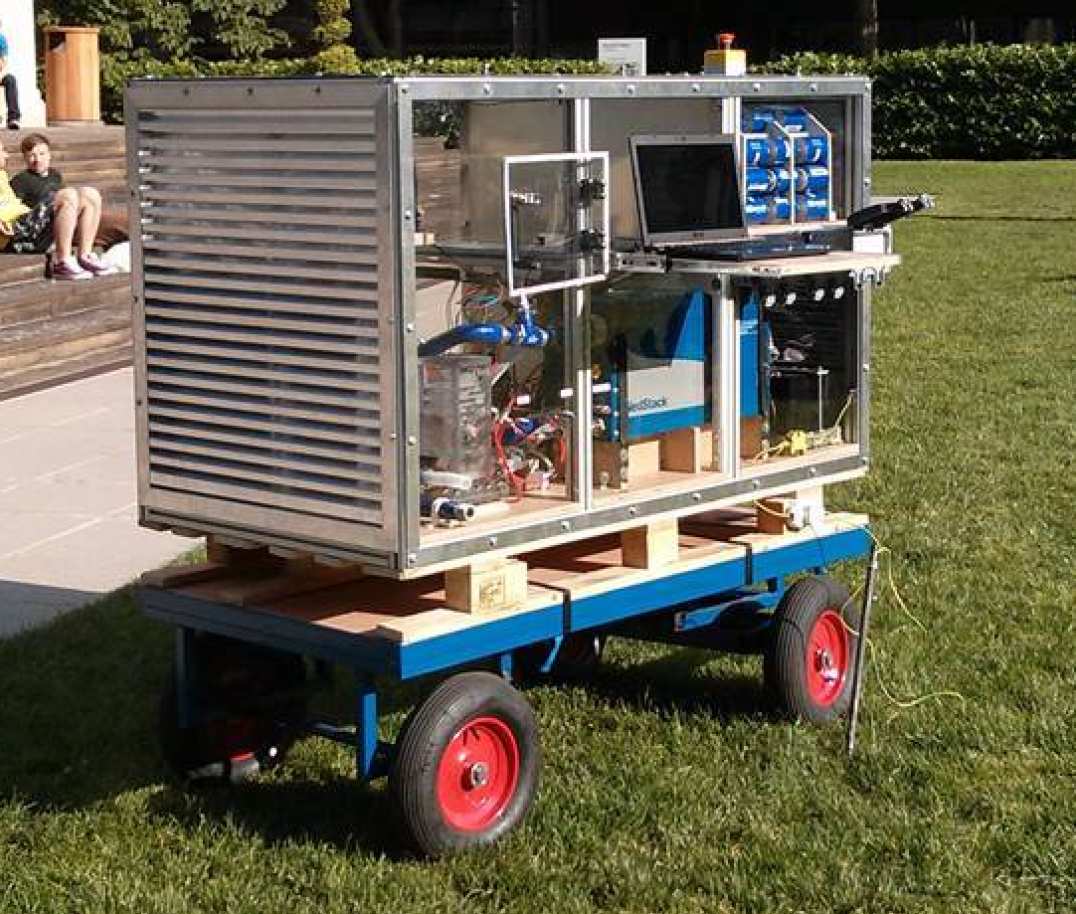

As part of the Racing Green programme at Imperial, which is an undergraduate teaching project aimed at developing fuel cell, battery and hybrid electric vehicles, I help to supervise the fuel cell research and development division of Racing Green with Dr. Greg Offer and Dr. Fred Marquis.

In the past, we have developed a 9.5 kWe low temperature proton exchange membrane fuel cell in collaboration with Johnson Matthey and Nedstack who provide the fuel cell components.

Check out when we took the FC power generator to BBC television studios and appeared on BBC Breakfast News and Blue Peter and when we appeared in the Hybrid and Electric Vehicles magaine.

Check out a demonstration of the zero-emission FC generator at the H2Supergen BBQ as well as video of the rig in action below.

http://www.youtube.com/watch?v=dcG6Rc--xlo

Design and testing of a 9.5 kWe proton exchange membrane fuel cell-supercapacitor passive hybrid system. Billy Wu et al. International Journal of Hydrogen Energy. 2014

The fuel cell-supercapacitor power generator

Publications:

A lung-inspired approach to scalable and robust fuel cell design. P. Trogadas, J.I.S.Cho, P. Neville, J. Marquis, B. Wu, D.J.L. Brett and M.-O. Coppens. Energy & Environmental Science. 2017

A systematic study on the use of short circuiting for the improvement of proton exchange membrane fuel cell performance. Gaurav Gupta, Billy Wu, Simon Mylius and Gregory Offer. International Journal of Hydrogen Energy. 2016.

Real-time monitoring of proton exchange membrane fuel cell stack failure. Billy Wu, Michael A. Parkes, Luca de Benedetti, Andrew J. Marquis, Gregory J. Offer and Nigel P. Brandon. Journal of Applied Electrochemistry. 2016

Design and testing of a 9.5 kWe proton exchange membrane fuel cell-supercapacitor passive hybrid system. Billy Wu, Michael A. Parkes, Vladimir Yufit, Luca De Benedetti, Sven Veismann, Christian Wirsching, Felix Vesper, Ricardo F. Martinez-Botas, Andrew J. Marquis, Gregory J. Offer and Nigel P. Brandon. International Journal of Hydrogen Energy. 2014

Hydrogen PEMFC system for automotive applications. Billy Wu, Mardit Matian and Gregory J. Offer. International Journal of Low Carbon Technologies. 2011

Redox flow batteries

Redox flow cells are electrochemical devices ideally suited for large scale grid energy storage applications. They store and release energy by changing the oxidation state of electrolyte which is pumped into an electrochemical cell, simialr to a fuel cell. They have advantages in that they can decouple power and energy which means that they can be sized more easily than battery technologies.

Featured research

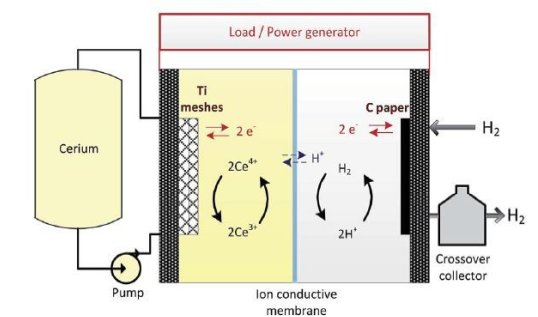

Flow batteries have the potential to have a lower cost than lithium-ion batteries for large scale energy storage however their low power density results in a high system cost. In this work we develop a novel hydrogen-cerium flow battery which has a higher operating voltage compared to traditional all vanadium flow batteries. This liquid-gas configuration also has the potential to enhance the rate-capability of the system enabling system down sizing.

A novel regenerative hydrogen cerium fuel cell for energy storage applciations. Harini Hewa Dewage et al. Journal of Materials Chemistry A. 2015

Publications:

The current and future prospects for vanadium flow batteries in China. Mianyan Huang, Eric Finlayson, Hanmin Liu, Jim Stover, Xiaofeng Xie, Billy Wu. The International Flow Battery Forum. 2017

A novel regenerative hydrogen cerium fuel cell for energy storage applciations. Harini Hewa Dewage, Billy Wu, Anthony Tsoi, Vladimir Yufit, Gregory Offer and Nigel Brandon. Journal of Materials Chemistry A. 2015

Additive manufacturing

Additive manufacturing, which is more commonly known as 3D printing, allows for the creation of complex geometries not possible with traditional subtractive techniques. His research activities in additive manufacturing include:

- Direct metal laser melting

- Fused deposition modelling

- Electrochemical additive manufacturing

- 3D printed chemical reactors

- Metrology and characterisation

Featured research

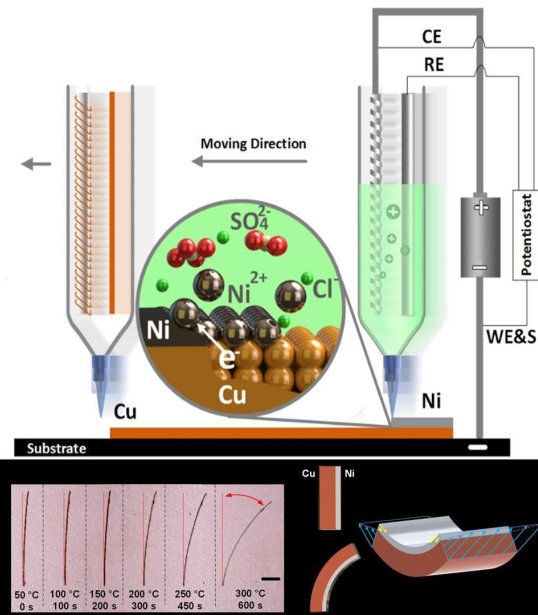

Direct metal laser melting is the main form of metal 3D printing however the high cost of the lasers and the need for inert gases limits its mainstream adoption. Electrochemical 3D printing is a low-cost method of achieving metal 3D printing without the need for high power lasers. Metal is deposited through the electrodeposition of metals from a solution. In our work we demonstrate the first multi-metal electrochemical 3D printing approach to make 4D structures.

Multi-metal 4D printing with a desktop electrochemical 3D printer. Xiaolong Chen et al. Scientific Reports. 2019

Publications

Electrospun composite nanofibre supercapacitors enhanced with electrochemical 3D printed current collectors. Xiaolong Chen, Xinhua Liu, Mengzheng Ouyang, Peter Childs, Nigel Brandon and Billy Wu. Journal of Energy Storage. 2019.

Multi-metal 4D printing with a desktop electrochemical 3D printer. Xiaolong Chen, Xinhua Liu, Mengzheng Ouyang, Jingyi Chen, Oluwadamilola Taiwo, Yuhua Xia, Peter Childs, Nigel Brandon and Billy Wu. Scientific Reports. 2019

The value of additive manufacturing: future opportunities. Billy Wu, Connor Myant and Shoshana Weider. 2017

A low cost desktop electrochemical metal 3D printer. Xiaolong Chen, Xinhua Liu, Peter Childs, Nigel Brandon, Billy Wu. Advanced Materials Technologies. 2017.

3D printed structural psuedocapacitors. Xinhua Liu, Rhodri Jervis, Robert C Maher, Ignacio J Villar‐Garcia, Max Naylor‐Marlow, Paul R Shearing, Mengzheng Ouyang, Lesley Cohen, Nigel P Brandon, Billy Wu. Advanced Materials Technologies. 2016

Electrical conductivity and porosity in stainless steel 316L scaffolds for electrochemical devices fabricated using selective laser sintering. Khairul Ibrahim, Billy Wu and Nigel Brandon. Materials and Design. 2016

The current landscape for additive manufacturing research. Jing Li, Connor Myant and Billy Wu. 2016.

Beyond the hype: 3D printing grows up. Billy Wu, Jing Li and Connor Myant. 2016.

Additive manufacturing for solid oxide cell fabrication. Marina Lomberg, Paul Boldrin, Farid Tariq, Gregory Offer, Billy Wu and Nigel Brandon. ECS Conference on Electrochemical Energy Conversion & Storage with SOFC-XIV

Group members

PHD STUDENTS

- Genlin Liu - Acoustic diagnostics of batteries (Co-supervised with Dr. Lorenzo Picinali and Dr. Yunlong Zhao)

- Charlotte Roe - Immersion cooling of lithium-ion batteries (Co-supervised with Dr. Chandra George)

- Yang Tu - Modelling of lithium-ion batteries (Co-supervised with Dr. Emilio Martinez-Paneda)

- Haamidah Sana - Additive manufacturing (Co-supervised with Professor George Britovesk)

- Oisin Shaw - Fuel cells (Co-supervised with Professor Gregory Offer)

RESEARCH ASSOCIATES/assistants

- Dr. Mayur Bonkile - Modelling of lithium-ion batteries

- Katie Lukow - Battery digital twins

ALUMNI

- Dr. Max Naylor-Marlow - Battery packs (Co-supervised with Dr. Mirko Kovac)

- Dr. Anna Tomaszewska - Battery fast charging (Co-supervised with Dr. Gregory Offer)

- Dr. Teddy Szemberg O'Connor - Thermal management of high power lithium-ion batteries

- Dr. Chenzhen Ji - Battery diagnostics and phase change materials for battery thermal management

- Dr. Weilong Ai - Modelling of lithium-ion batteries

- Dr. Jorge Varela Barreras - Modelling of lithium-ion batteries

- Dr. Ganesh Madabattula - Lithium-ion capacitors

- Dr. Jingyi Chen - Modelling of lithium-ion batteries

- Dr. Xiaolong Chen - Additive manufacturing (Co-supervised with Professor Peter Childs)

- Natasha Figg - Battery pack design tools

- Dr. Ashkan Kavei - Proton Exchange Membrane Fuel Cells (Co-supervised with Professor Nigel Brandon and Dr. Vladimir Yufit)

- Dr. Xinhua Liu - Battery materials and manufacturing

- Dr. Tasnuva Khaleque - Additive manufacturing of solid state hydrogen storage reactors

- Dr. Yu Merla - Lithium-ion batteries (Co-supervised with Dr. Gregory Offer)

- Dr. Gan Lu - Design and optimisation of fuel cell powertrains (Co-supervised with Dr. Gregory Offer)

- Dr. Gaurav Gupta - Post-doc - Proton exchange membrane fuel cells (Co-supervised with Dr. Gregory Offer)

- Dr. ChiYoung Choi - Post-doc - Proton exchange membrane fuel cells (Co-supervised with Dr. Gregory Offer)

- Dr. Jing Li - Post-doc - Additive Manufacturing Network manager (Co-supervised with Dr. Connor Myant)

Projects

- BAFTA (Battery Advances for Future Transport Applications) - Innovate UK funded project on development of battery pack design tools, cell diagnostics and state-estimation. Partners: Aston Martin and Dukosi.

- Mat2Bat - Innovate UK funded project on the development of battery pack design tools. Partners: Ansys (Granta) and Denchi Power.

- HyStERIAA (Hydrogen Storage to Energise Robotics In Air Applications) - Innovate UK funded project to develop 3D printed solid state hydrogen storage reactors. Partners: H2GO Power.

- Faraday Institution Multi-Scale Modelling - EPSRC funded project on modelling lithium-ion batteries

- ABLE (Advanced Battery Lifetime Extension) - Innovate UK funded project on the use of 2nd life batteries in solar home systems. Partners: M-Kopa Solar and Denchi Power.

- IMPACT (IMproved Power bAttery Cooling Technology) - Innovate UK funded project on cooling technologies for high power batteries. Partners: Arcola Energy, Flint Engineering, Reaction Engines and Brunel University.

- Joint UK-India Clean Energy Centre (JUICE) - EPSRC funded centre between the UK and India for the integration of renewable energy

- ALICE (Advanced Lithium-Ion Capacitor Electrodes) - Innovate UK funded project on scale up of lithium-ion capacitor technology. Partners: Johnson Matthey, Cummins, Delta Motorsports, WMG and Oxford University.

- ZEBRA (Zero Emission Buses by Range Extension with fuel cells) - Innovate UK funded project on integration of hydrogen fuel cells into buses. Partners: Arcola Energy.

- Imperial Additive Manufacturing Network - Imperial College funded network fund to bring together researchers working in additive manufacturing

- Materials and process development for low cost 1-10kW UK fuel cell stack manufacturing - Innovate UK funded project to develop fuel cell manufacturing capability in the UK. Partners: Arcola Energy.

- Lithium-ion battery modelling for power network optimisation and whole system analysis - EPSRC funded project to develop lithium-ion battery models for grid optimisation purposes.