High Accuracy Ultrasonic Monitoring of Metal Components

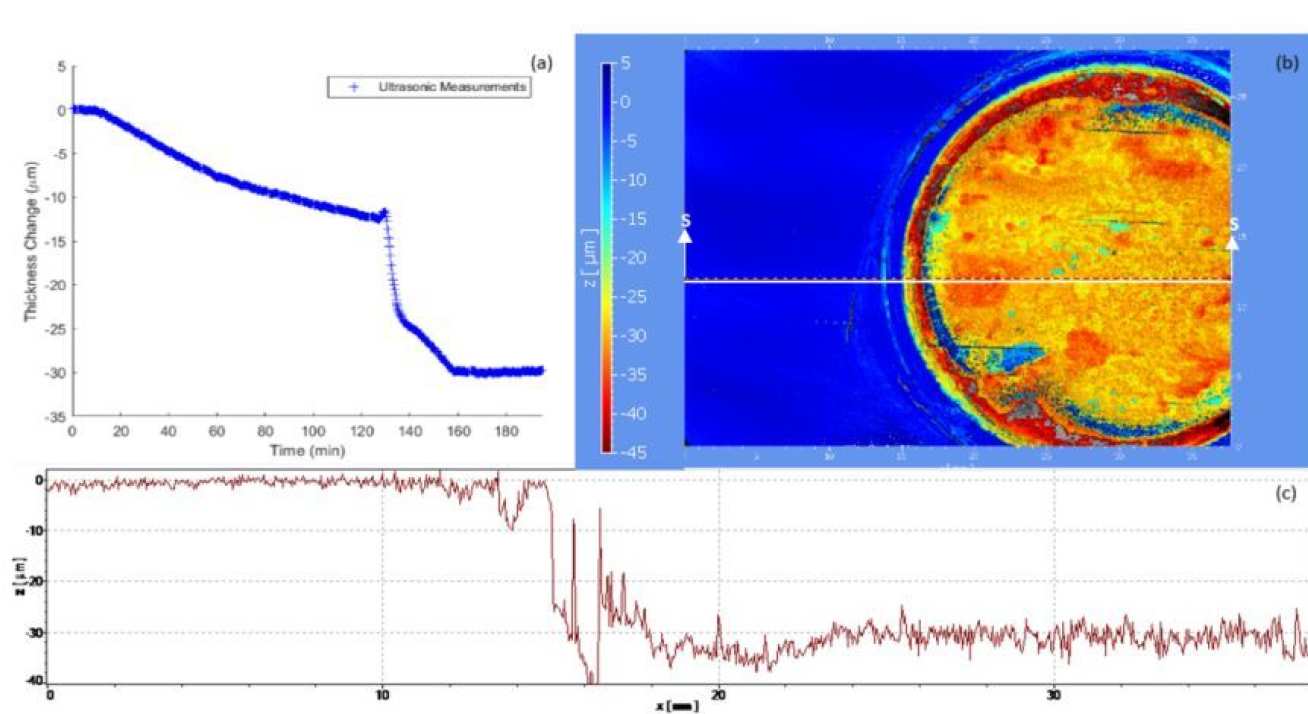

Surface phenomena such as corrosion and oxidation are difficult to observe but failure to understand them can lead severe consequences, financial loss and even casualties. In a very well controlled laboratory environment, the precision of in situ ultrasonic wall thickness tracking can attain the order of tens of nm. However, its precision deteriorates rapidly with widening temperature range and transient heat flux. The project will first investigate advanced temperature compensation strategies to improve the resolution and robustness of the ultrasonic wall thickness tracking technique.

In addition, recent studies revealed that certain oxides and corrosion products exhibit corrosion inhibiting effects and can potentially be used as natural corrosion inhibitors. Knowledge about their formation mechanisms and corrosion inhibitive capabilities can be greatly enhanced if thickness of the deposition layer can be measured in situ. Ultrasonic waves are sensitive to changes of material acoustic properties and can thus be used for monitoring material deposition. This project will then explore the use of ultrasonic transducers to monitor complex surface chemical reactions where wall-thinning corrosion and film deposition occur concurrently.