Permanently Installed Crack Monitoring

Motivation:

Monitoring cracks in critical sections of steel structures can be advantageous because it reduces the access cost for repeated inspection, improves detection sensitivity and improves accuracy of crack growth rate prediction.

Existing Problem:

Existing high frequency ultrasonic techniques have good detection sensitivities but poor inspection coverage, which would require an impractical number of transducers to monitor large areas such as welds. Low frequency guided waves have relatively higher inspection coverage and are used for corrosion detection in long-range, guided wave inspection of pipelines, but possess insufficient sensitivity for many crack detection applications.

Solution:

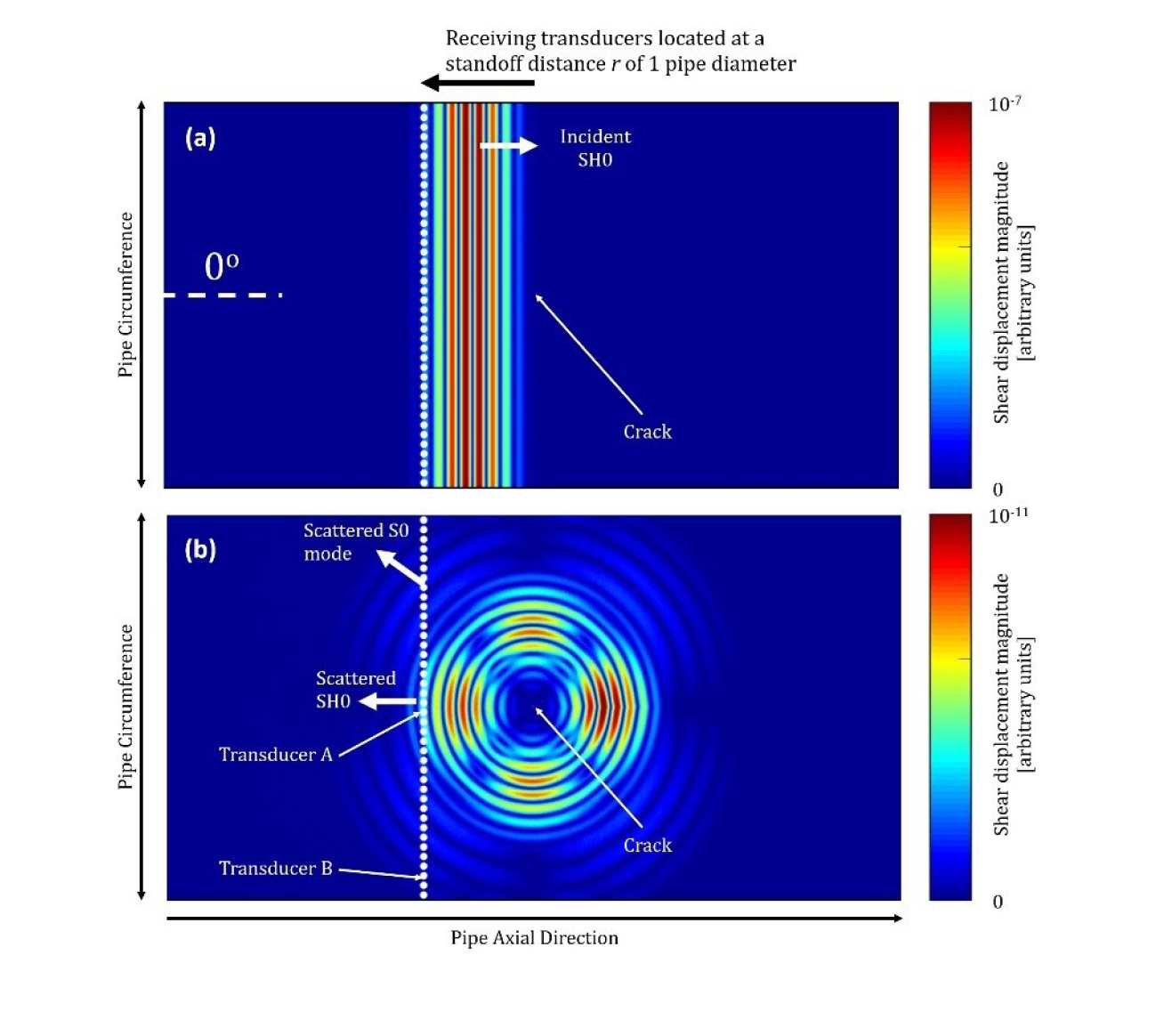

This project focuses on the use of a short-range monitoring system that uses relatively high-frequency SH0 guided waves to monitor critical sections, by exploiting the capture of relatively high-energy scattered SH0 waves and baseline subtraction for signal-to-noise improvement.