Development of Non-Destructive Ultrasonic Detection Methods of Macrozones within Titanium Alloys

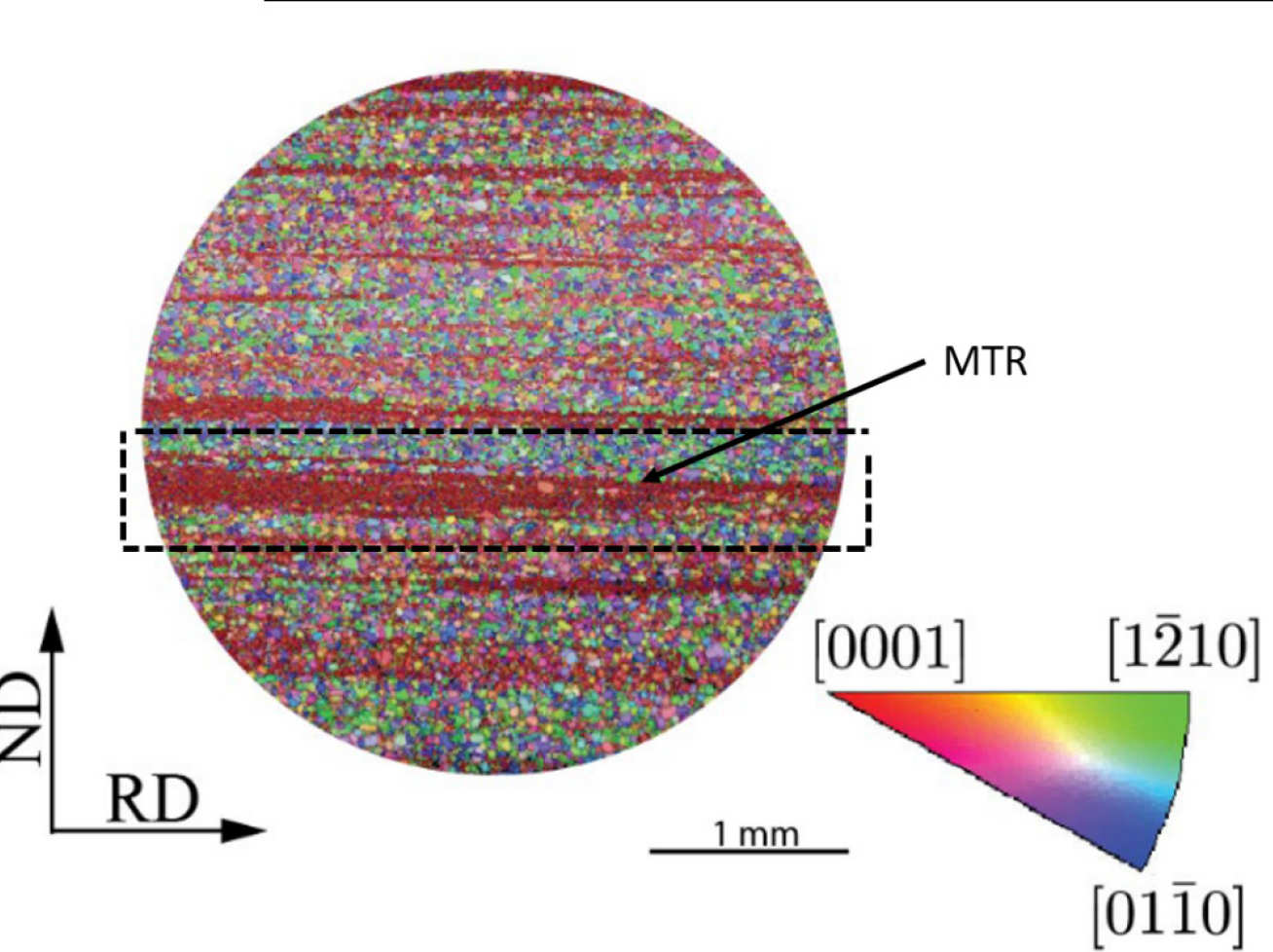

Titanium Alloys used within aero engine blades and disks are prone to suffering from Cold Dwell Fatigue (CDF), which occurs due to the complex loading cycle (load hold) they experience during flight. It is believed that the microstructure within the material is a leading factor in the severity of the dwell debit experienced by a given component. A material’s microstructure is effected by its processing history, and some processing methods may lead to the formation of regions of commonly oriented grains called Macrozones or Micro Textured Regions (MTRs). MTRs may vary in their size and morphology; hence their effect upon the dwell debit severity will also vary. The aim of this project is to firstly characterise which types of MTRs lead to a greater dwell debit through materials fatigue testing; once this is established the aim is to create a non-destructive method to reliably detect and characterise these MTRs. This work will build upon existing texture characterisation techniques which have been previously developed by the NDE group at Imperial.