Water Electrolysis Hall Effect Thruster

Motivation and background

The dramatically rising price of xenon is driving the Electric Propulsion (EP) community to consider alternative propellants to meet the requirements of tomorrow. Like xenon, the ideal electric propellant must be easy to ionize, storable at high densities and chemically compatible with the thruster and the accompanying cathode.

So far, no current or proposed EP propellant has achieved this. Much like xenon, krypton is widely chemically inert and easy to ionize; however, the poor storage density of krypton has stopped widescale adoption. Another contender is iodine, which has fantastic storability due to it being stored as a high dense solid. A major issue with iodine is that it is not chemically compatible with traditional hollow cathodes.

We conceptualize an EP system in which water is utilized as a propellant by using in situ electrolysis. Water cannot be used as an EP propellant itself due to it reacting aggressively with the emitters within traditional hallow cathodes. Hydrogen has been shown to be very compatible with these cathodes. By supplying the oxygen from electrolysis to the thruster anode and the generated hydrogen to the hollow cathode, poisoning of the cathode emitters is mitigated. Such a system can benefit from the low cost, high storability and in situ resource utilization potential of water.

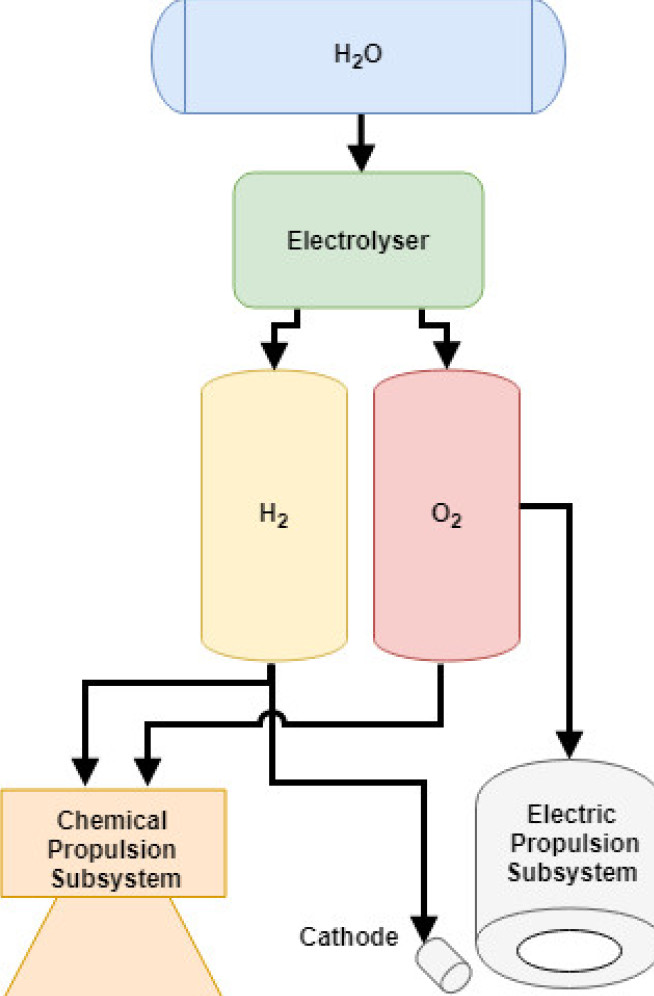

A water electrolysis EP system can offer exciting synergies with water electrolysis chemical propulsion systems, allowing for a single spacecraft to fly with both, for a multi-mode chemical-electrical propulsion architecture, as shown in figure 1. Water electrolysis can also be combined with fuel cells as an energy storage mechanism which can provide considerable mass savings over current lithium-ion batteries.

Approach

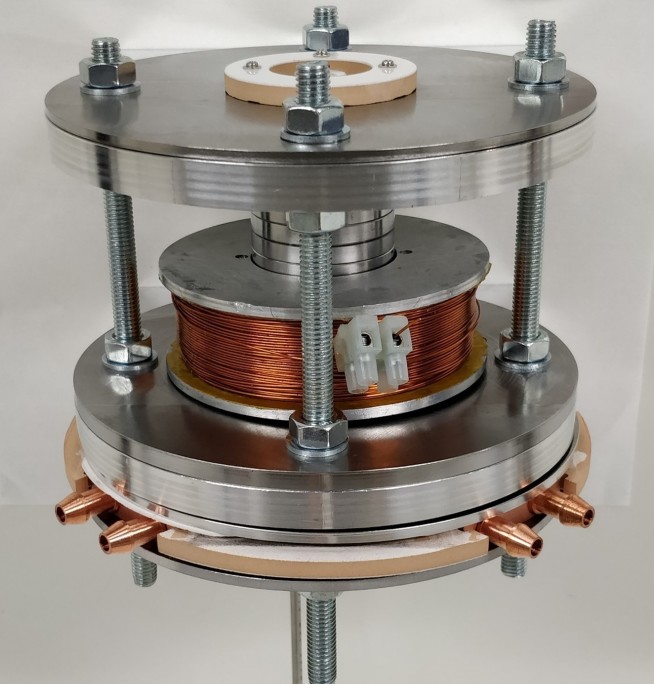

We have designed a Hall effect thruster (HET) optimized to operate on oxygen as a proof of concept for a water electrolysis EP system. Our design process began with zero dimensional kinematic Boltzmann solver to simulate the energy lost to the covalent bonds of the oxygen molecules in an environment similar to a HET. Next, we reduced the complexity of IPPL's PlasmaSim code to optimize the geometry of a HET to operate on oxygen. The water electrolysis Hall effect thruster (WET-HET) was designed from this optimized geometry. Iterative magnetic, thermal, and CAD modelling led to the final design that was manufactured in house (figure 2).

We have built the WET-HET prototype to serve as a testbed to experimentally characterize different thruster configurations and operating points for oxygen discharges. In comparison to traditional propellants, oxygen has a far smaller ionization cross section which results in a lower ionization fraction and thrust efficiency. To account for this we have designed the WET-HET thruster to have the unique ability to have both its magnetic topology and its channel depth to be dramatically varied in the laboratory. This allows us to explore a range of physical and magnetic configurations which differ substantially from those seen with typical xenon thrusters. We believe that thicker magnetic regions and deeper channels will increase the residence time of the neutrals, promote ionization, and ultimately increase the thrust efficiency of the device.

In March 2020 we began to characterize the WET-HET firing in the Boltzmann vacuum facility. We performed direct thrust measurements using a hanging pendulum style thrust balance which we developed in collaboration with ESA [1]. We have tested the thruster with different ceramic wall materials, at massflows ranging from 0.96mg/s to 1.85mg/s, and at discharge powers ranging from 400W to 1600W. We have changed the magnetic topology to determine how increasing the magnetic depth effects thruster performance.

Obtained and/or anticipated results

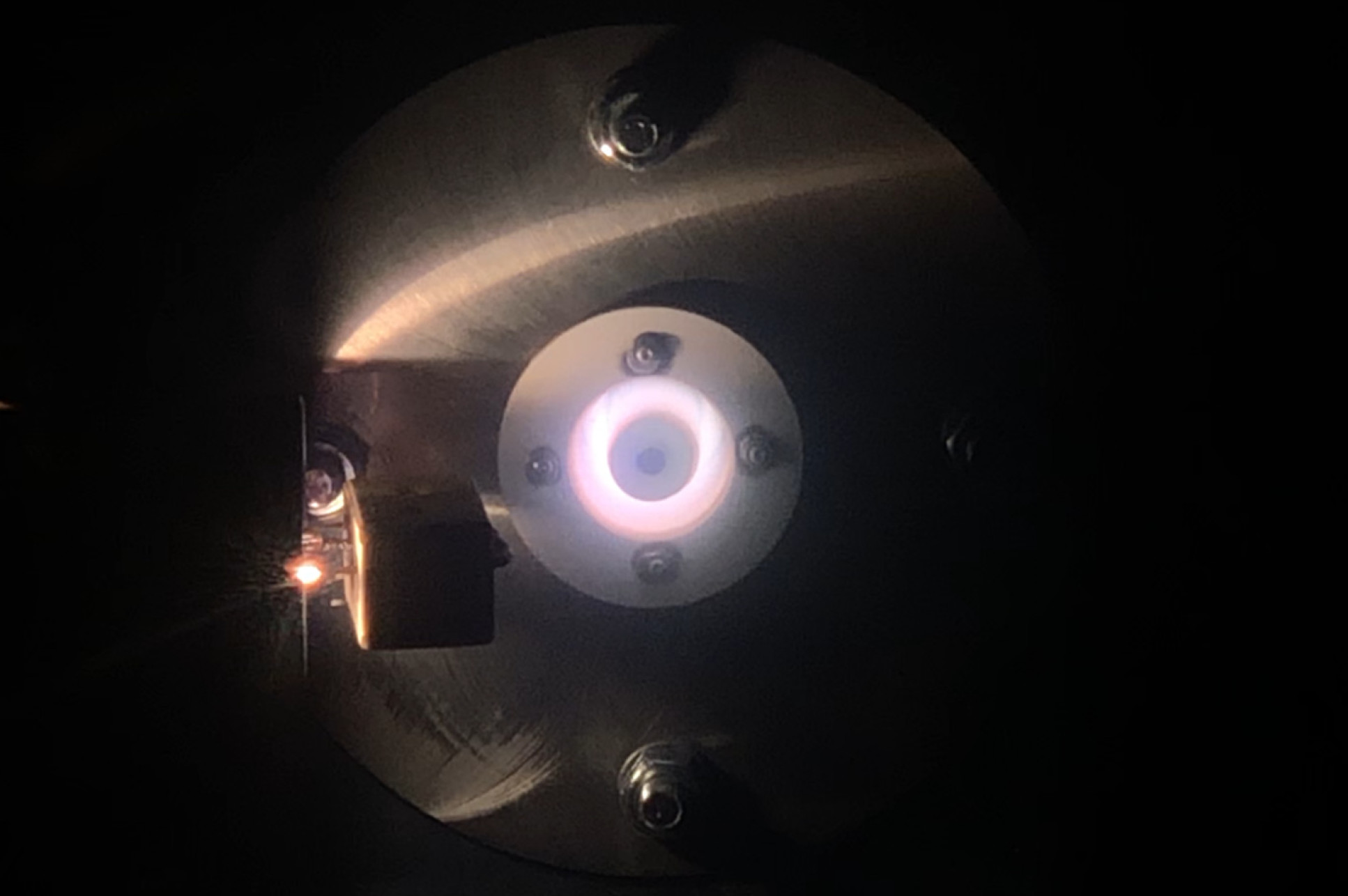

To date we have measured the WET-HET producing thrust ranging from 4.52±0.18 mN to 14.75±0.24 mN, specific impulses ranging from 324±12 s to 1570±26 s, and anode thrust efficiencies which range from 1.34±0.10 % to 8.0±0.27 % [2,3]. The thruster is shown operating in figure 3.

When changing the magnetic field topology, we have found that thicker magnetic fields reduce the thrust, specific impulse and thrust efficiency.

We have found that changing the discharge channel material from alumina to boron nitride increased the thrust generated by approximately 40% [3].

When operating at a discharge power of 1550 W, the WET-HET produces a very similar specific impulse to a comparable xenon thruster at the same discharge power. At this setpoint, the WET-HET operates at approximately 1/5th the massflow, meaning it has 1/5th the thrust, hence a considerably lower anode thrust efficiency. While the WET-HET cannot compete with a xenon thruster on performance alone, we believe that the device has demonstrated great potential due to system level advantages such propellant cost, storability, and availability, and the potential for synergy with chemical propulsion systems.

Relevant publications

- Schwertheim A., Rosati Azevedo E., Liu G., Bosch Borràs E., Bianchi L., Knoll A. (2021). Interlaboratory validation of a hanging pendulum thrust balance for electric propulsion testing. Review of Scientific Instruments 92, 034502. https://doi.org/10.1063/5.0037100

- Schwertheim A., Knoll A. (2021). Low power thrust measurements of the water electrolysis hall effect thruster. EAS Space Journal, 1–15. https://doi.org/10.1007/s12567-021-00350-y

- Schwertheim A., Knoll A. (2021). Performance characterisation of the water electrolysis hall effect thruster (wet-het) using direct thrust measurements. Space Propulsion Conference 2020+1, 17 - 19 March 2021. (Full-text available on ResearchGate)