Improved Guided wave inspection of buried and coated structures

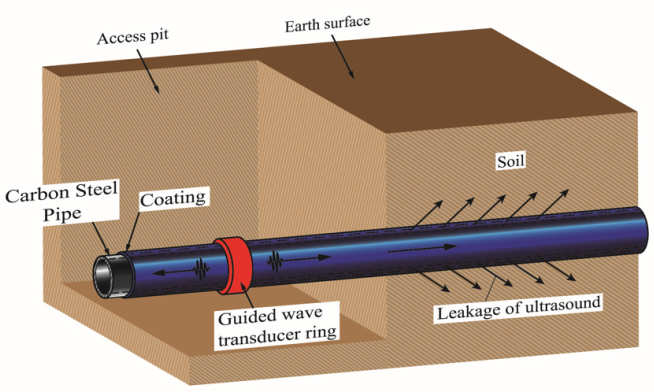

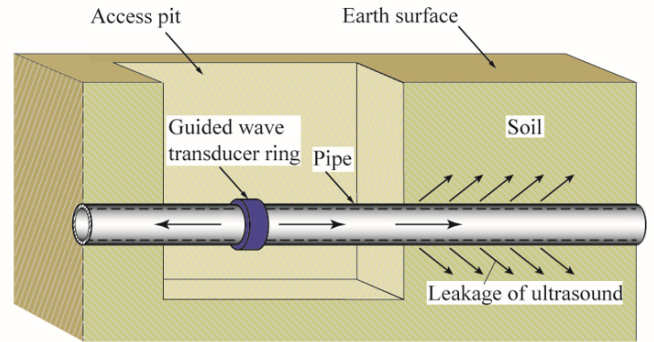

The inspection of pipelines by long-range Guided Wave Testing (GWT) has been routinely used for over a decade in a variety of applications in the petrochemical, power and nuclear industries. The method employs ultrasonic signals guided by the inspected structure and offers the possibility of rapid screening over long lengths of pipework for the detection of corrosion and other defects. The common application of the method is to bare- or thinly epoxy-painted pipes. However, when the method is applied to pipes buried in soil, test ranges tend to be significantly reduced compared to bare pipes and unpredictable as the attenuation varies from case to case. Buried pipes are generally tested by digging a pit to expose the pipe where the transducer ring is to be attached and then testing as far as possible in each direction from this position.

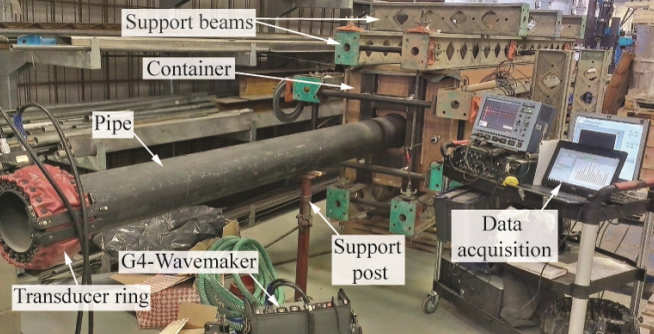

A comprehensive full-scale experimental investigation has been undertaken to characterise the damping of guided waves propagating in pipes buried in sand under a range of controlled physical conditions. Model predictions were used to reproduce the experimental results and to gain better understanding of the dominating physical mechanisms, providing the scientific basis for the improved inspection of buried pipes.

Typically for modern pipeline engineering practices, coating materials, e.g. fusion-bonded epoxy (FBE), coal-tar-enamel and high-density polyethylene (HDPE), are either factory- or field-applied to pipes that are buried in the ground in order to provide insulation from harsh environments and protection from corrosion. The guided wave attenuation in coated or embedded waveguides is due to leakage of energy radiating out into the embedding material, and damping by energy-absorbing materials of the waveguide system, resulting in a severe reduction of the test range. The extent of leakage depends on the material properties of both the pipe and the embedding material.

The work conducted on buried-coated-pipes has shown the attenuation is essentially governed by the acoustic impedance contrast between the pipe and the soil. This has led to the development of a designated pipe-coating that offers ultrasonic isolation to buried pipes, effectively reducing the attenuation of guided wave modes in the pipe by decoupling the influence of the soil on the pipe. The large reduction in guided wave attenuation for ultrasonically isolated pipes would lead to greatly increased GWT test ranges; such coatings would be attractive for new pipeline installations.

References

- Leinov E, P Cawley and MJS Lowe. 2014 Investigation of guided waves propagation in pipe buried in sand. The 40th Annual Review of Progress in QNDE, Baltimore, USA.

- Leinov E, P Cawley and MJS Lowe. 2014 Guided wave attenuation in pipes buried in sand. The 41st Annual Review of Progress in Quantitative Nondestructive Evaluation (QNDE). Boise, USA.

- Leinov E, P Cawley and MJS Lowe. 2015 Guided wave attenuation in coated pipes buried in sand. The 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation (QNDE). Minneapolis, USA.

- Leinov E, MJS Lowe and P Cawley. 2015 Investigation of guided waves propagation and attenuation in pipes buried in sand. Journal of Sound & Vibration, Vol. 347, 96-114. (doi:10.1016/j.jsv.2015.02.036)

- Leinov E, MJS Lowe and P Cawley. 2016 Ultrasonic isolation of buried pipes. Journal of Sound & Vibration. Vol. 363, 225-239. (doi:10.1016/j.jsv.2015.10.018)