Dunne widget

- Microstructure modelling of irradiated Zr alloys under long-term thermo-mechanical cycles

- In-site characterisation of load shedding in macrozones during dwell fatigue in Ti-6Al-4V

- Peridynamics and finite element crystal plasticity modelling oxidation of Zr alloys

- Alloying for impurity tolerance

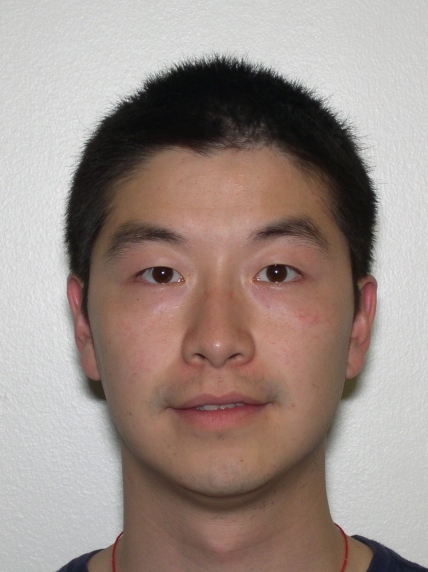

Dr Yang Liu (Research Associate)

Dr Yang Liu (Research Associate)

In collaboration with Rolls-Royce plc and UKAEA

Fatigue crack nucleation in Zr alloys under reactor-relevant conditions involves multi-physics conditions and is sensitive to the local microstructure. The model prediction and microstructure evaluation are crucial to long-term structural integrity assessment for these materials. This project aims to couple and incorporate the relevant physical mechanisms in burn-up zirconium alloy to investigate its mechanistic phenomenon compared with experimental observations.

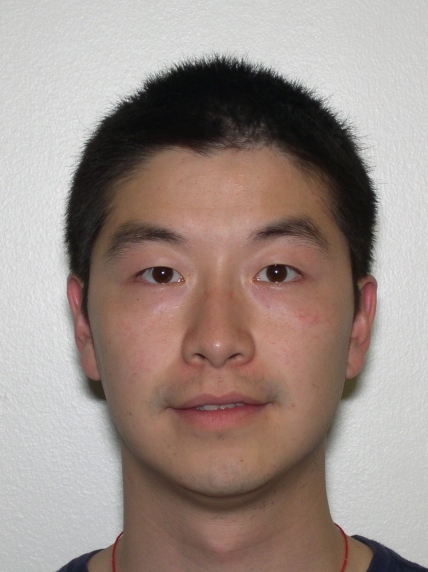

Yu Cao (Research Postgraduate)

Yu Cao (Research Postgraduate)

In collaboration with IHI

Cold dwell fatigue is a key failure mechanism in titanium alloys which considerably reduces life span. An important factor potentially influencing the susceptibility to dwell fatigue is the duration of the dwell time and its role in load shedding. My project is addresses in-situ high-resolution (optical) digital image correlation (DIC) characterisation of strain and resulting intragranular stress redistribution within macrozones, which takes place during stress dwell-loading in three-point bending tests. Stresses are estimated from knowledge of measured strains both during the stress hold and at the unloaded state. Hence spatially resolved creep and stress redistribution within hard and soft macrozones inside Ti-6Al-4V alloy have been quantified during dwell showing experimentally for the first time the explicit redistribution of stress onto grains badly orientated for slip. In addition, it has been possible to quantify the time constant associated with the redistribution in this alloy, which is compared with the results of a theoretical approach, facilitating comparison with other important Ti alloys.

Susannah Lea (Research Postgraduate)

Susannah Lea (Research Postgraduate)

Co-supervised by Dr Mark Wenman

Member of Nuclear Energy Futures CDT

The aim of the project is to understand the growthbehaviour of zirconium oxide and how the oxide layer affects hydrogen pickup. Currently hydrogen pickup is the life limiting factor for nuclear fuel, due to embrittlement by hydride formation and determining the oxide growth is key to understanding this, since there have been links made between parabolic and sub-parabolic growth of the oxide and hydrogen uptake. There is a transition associated with the formation of cracks at an oxide thickness of 1-2 microns and just before this transition is when the hydrogen uptake increases. Stress relief is a possible cause of crack nucleation, as the stress within the oxide increases with growth.

This project will develop an oxygen diffusion model where metal turns into oxide and includes the oxide expansion, leading to the stress states in both the oxide and underlying metal. The crack nucleation and growth in the oxide will also be explicitly modelled and linked to the metal microstructure. This will be validated by characterisation work of cracks at the microscale carried out by Jacobs and Rolls-Royce. The project will link a crystal plasticity model for Zircaloy-4 with models of brittle fracture of ceramics utilising a technique called peridynamics. This will be done in Abaqus by pinning a peridynamics mesh to a finite element mesh with tie constraints, so that stress in the oxide will drive deformation in the underlying metal and also back again into the oxide, leading to damage and cracks.

Katlo Batsile (Research Postgraduate)

Katlo Batsile (Research Postgraduate)

Co-supervised by Dr Daniele Dini and Dr Stella Pedrazzini

Member of Science Solutions for a Changing Planet Doctoral Training Partners & Transition to Zero Pollution

Recycling is an important aspect of the steel and iron industry's effort to attain circularity. However, one of the challenges pertains to the presence of impurity elements which accumulate with continued recycling, causing the deterioration of important mechanical properties like ductility and impact toughness of the steel. As a result, recycled steel has limited potential in high-value applications. In uncontrolled amounts, copper can be particularly detrimental, and understanding its effects on steels, the influence of elemental additions, and thermo-mechanical processing on mechanical properties is key to the design of impurity tolerant alloys. Through the use of advanced microscopy techniques and atom probe tomography, we aim to characterise the segregation of this impurity element and any changes as a result of alloying additions.