Composite Characterisation facilities

X-radiography

Digital X-ray inspection can be performed using our stand alone x-ray system. This equipment allows fast and easy x-ray inspection of parts. If required, we can treat our composite parts with a contrast media for better defect detection.

Digital X-ray inspection can be performed using our stand alone x-ray system. This equipment allows fast and easy x-ray inspection of parts. If required, we can treat our composite parts with a contrast media for better defect detection.

- Energy range: 10 kV – 100 kV

- Tube Current: 180 mA – 1.0 mA

- Resolution: 5-45 µm

- Maximum sample size 350mm x 430 mm

- Chamber height 410mm

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

TAS thermal vacuum chamber

We have a Thermal Vacuum Chamber manufactured by Temperature Applied Sciences LTD

We have a Thermal Vacuum Chamber manufactured by Temperature Applied Sciences LTD

- Temperature range -70 to 180°C

- Pressure range ambient to 185kPa absolute

- Vacuum range ambient to -2kPa absolute

- Humidity range 10 to 98%

- Temperature ramp rate 5.2°C/min linear heating and cooling (-55 to + 80°C payload 500 x 500mm aluminium sheet 700g)

- Chamber dimensions 500mm Dia x 500mm depth

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

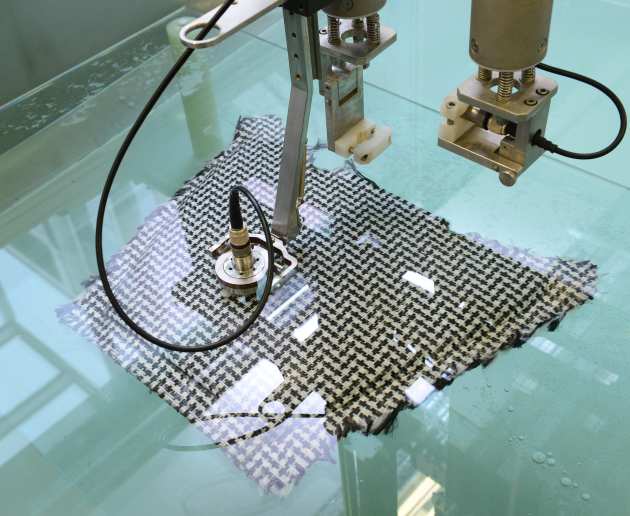

Ultrasonic inspection

We inspect manufactured and tested panels and parts using our Ultrasonic C-scan. The large tank allows even large structures to be inspected. Curved specimens can be analysed, using a device to ensure that the ultrasonic probe is aligned normal to the test surface throughout the scan. In addition to the pulse-echo set-up, we can also test in through transmission mode. A portable, hand-held ultrasonic inspection device (DolphiCam) is also available which does not require the specimen to be immersed in water. This allows inspection of composite parts of up to 8mm thickness in the field.

We inspect manufactured and tested panels and parts using our Ultrasonic C-scan. The large tank allows even large structures to be inspected. Curved specimens can be analysed, using a device to ensure that the ultrasonic probe is aligned normal to the test surface throughout the scan. In addition to the pulse-echo set-up, we can also test in through transmission mode. A portable, hand-held ultrasonic inspection device (DolphiCam) is also available which does not require the specimen to be immersed in water. This allows inspection of composite parts of up to 8mm thickness in the field.

- Immersion tank: 1700 x 1300 x 500 mm

- Max. scanning speed: 500mm/s

- Min. acquisition index: 0.1mm

- Probes 1MHz – 15MHz

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Optical microscopy

We do have a dedicated materials lab for micrography and fractography inspection of composite materials. Our Zeiss optical microscope is equipped with a motorised stage. This allows automated imaging of large areas at high magnification, including image stitching.

We do have a dedicated materials lab for micrography and fractography inspection of composite materials. Our Zeiss optical microscope is equipped with a motorised stage. This allows automated imaging of large areas at high magnification, including image stitching.

- Mangification...

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Inspection microscopy

We do have a dedicated materials lab for micrography and fractography inspection of composite materials. Our Olympus stereo optical microscope is equipped a variety of light sources. This allows automated imaging of large areas at high magnification, including image stitching.

We do have a dedicated materials lab for micrography and fractography inspection of composite materials. Our Olympus stereo optical microscope is equipped a variety of light sources. This allows automated imaging of large areas at high magnification, including image stitching.

- Magnification...

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Scanning electroni microscopy

We have a scanning electron microscopy (thermionic emmission) with a large chamber which is dedicated to characterisation of polymeric composites.

We have a scanning electron microscopy (thermionic emmission) with a large chamber which is dedicated to characterisation of polymeric composites.

- Magnification...

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

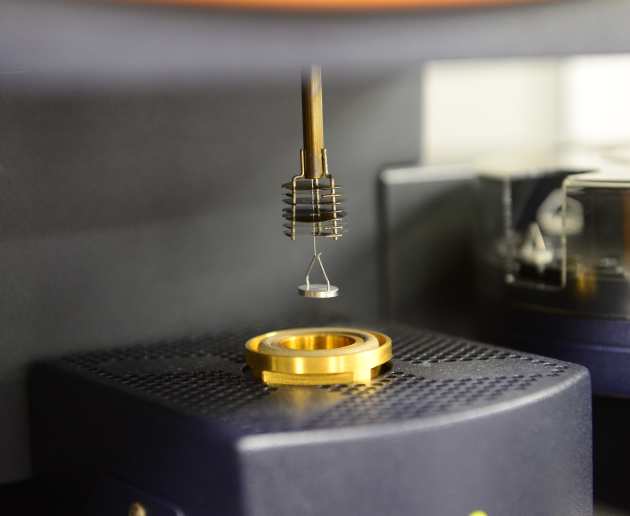

Glovebox and potentiostat

For assembly and characterisation of multifunctional materials we have a glovebox which permits assembly of materials under an inert (argon) and moisture free atmosphere. We can characterise the resulting electric devices with our potentiostat

For assembly and characterisation of multifunctional materials we have a glovebox which permits assembly of materials under an inert (argon) and moisture free atmosphere. We can characterise the resulting electric devices with our potentiostat

Technical Details:

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Dynamic mechanical thermal analysis (DMTA)

For characterisation of polymeric materials we have.

For characterisation of polymeric materials we have.

Technical Details:

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Differential scanning calorometry (DSC)

For characterisation of polymeric materials we have.

For characterisation of polymeric materials we have.

Technical Details:

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Contact us

The Composites Centre

Imperial College London

South Kensington Campus

London

SW7 2AZ

United Kingdom

Email: ae.composites@imperial.ac.uk