Research and development associated with the mechanical characterisation of composite materials and components is undertaken in the Composite Centre. Such studies provide an insight into the damage and failure mechanisms in these materials, and provide validation for predictive models. We have considerable experience in undertaking standard test methods for characterisation of new and current composite materials. But we have particular expertise in development of bespoke test methods to characterise composite materials, elements and components.

Measurements of the high strain rate response of advanced materials

Dr V. L. Tagarielli, Prof P. Curtis

Strong and brittle materials such as high performance fibres, composites and ceramics are often used in applications which involve intense dynamic loading. The measurement of their performance at high strain rates is therefore fundamental; however, established test methods, based on the Hopkinson's bar technique, are unable to provide reliable data due to the difficulty in achieving dynamic equilibrium in the tests.

Strong and brittle materials such as high performance fibres, composites and ceramics are often used in applications which involve intense dynamic loading. The measurement of their performance at high strain rates is therefore fundamental; however, established test methods, based on the Hopkinson's bar technique, are unable to provide reliable data due to the difficulty in achieving dynamic equilibrium in the tests.

We have developed a new test technique which allows reaching a very early dynamic equilibrium in mechanical tests and therefore provides valid dynamic measurements of the tensile stress versus strain curve in both the elastic and inelastic regimes. The new technique allows, for example, tensile testing of arbitrary lengths of high performance fibres, yarns, and monolithic materials, at strain rates up to 10000/s and in different environmental conditions including high and low temperature.

Delamination

Prof Greenhalgh, Prof P. Robinson

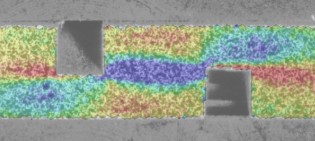

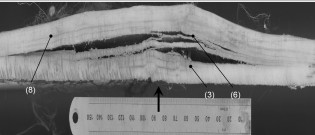

The Group at Imperial College has pioneered understanding, characterisation and development of modelling methodologies for delamination growth in composites. Researchers at Imperial College have led development of standard test methods to characterise delamination toughness of composites under mode I, II and mixed-mode (I/II) delamination. They have developed methods to characterise delamination resistance at high rates and under cyclic loading, which have provided validation for the development of delamination failure criteria. More recently, the Group has worked on delamination growth at non-zero ply interfaces, using fractographic insights to motivate the development of new test methods to characterise delamination migration processes. This has led to the development of novel test methods to characterise mode III and mode II/III delamination toughness. These profound insights into delamination growth processes have underpinned predictive model development and formulation of methodologies for damage tolerant design.

Environmental effects on composites

Prof E Greenhalgh, Prof S Pinho, Dr S Pimenta, Prof P. Robinson

The CTi project is in collaboration with Rolls Royce and University of Bristol, to characterising the influence of moisture, temperature and rate on the mechanical performance of highly toughened aerospace composites. Testing is being undertaken on interlaminar, intralaminar and translaminar loading modes, and the results are complemented by fractographic studies. Testing of these materials is presenting new challenges due to the heterogenous microstructure and interply toughened region. By investigating the equivalence of the fracture processes under different environmental conditions, we are developing new TTSP (time-temperature-humidity superposition principle) models which link rate, temperature and moisture effects in these materials. The overarching aim is by demonstrating equivalence under certain conditions, verified through fractographic observations, the certification process for components made from these materials can be shortened.

Translaminar Fracture Toughness

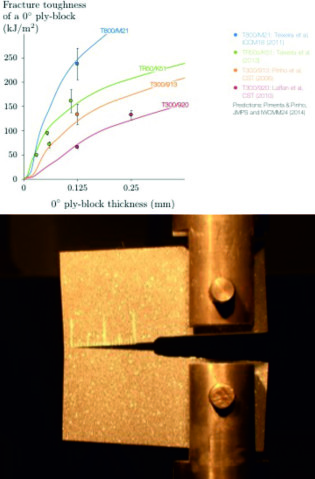

Silvestre T Pinho, Paul Robinson, Lorenzo Iannucci, Soraia Pimenta, Norbert Blanco (U Girona)

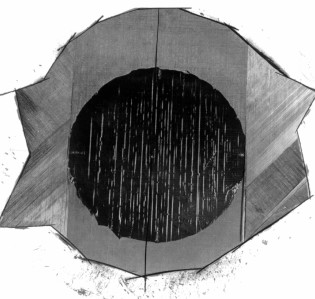

The translaminar fracture toughness of CFRP plies and laminates defines how translaminar cracks may propagate through a laminate. We proposed and demonstrated a test method to measure this property over a decade ago to permit, for the first time, a smeared crack approach for laminated composites. This is now the most widely adopted test method to measure this property. Over the last decade, we have used this test method to characterise different material systems, fibre architectures, recycled composites, size effects, and have also adapted the specimen design and test method to suit a variety of emerging materials.

Papers on this research can be found here [1,2,3,4,5,6,7,8,9,10,11,12].

Blast performance of composite sandwich panels

Prof J P Dear, Dr P Hooper, Dr H Arora

This research group has continued to develop and test composite sandwich panels against full-scale explosive charges, pushing the materials to their limits yet demonstrating their exceptional blast resilience. The high strength-to-weight ratios and energy absorption capabilities of composite sandwich panels make them an attractive choice for many demanding applications, including within the defence sector. The group has developed reliable large-scale experimental techniques to record panel response during air and underwater blast events.

Impact on composites

Prof L Iannucci, Prof E Greenhalgh, Prof P Robinson

Impact, and its subsequent effects on the mechanical performance of composite structures, has been an important focus of the research in the Composites Centre. We have characterised impact response and thresholds, the influence of impactor and component parameters, and issues such impact whilst under load. In parallel we have developed predictive models for the impact response, damage threshold, damage development and residual performance. We have investigated a spectrum of impact conditions, from low velocity impacts, medium velocity (e.g. runway debris) to high velocity (e.g. ballistic impact).

Contact us

The Composites Centre

Imperial College London

South Kensington Campus

London

SW7 2AZ

United Kingdom

Email: ae.composites@imperial.ac.uk