lab facilities

Structures Testing Lab

Lab includes a recent £14 M investment in infrastructure and equipment to provide a prestigious facility in the UK university sector for research into engineering structures.

- £1.9 M investment in new servohydraulic test equipment including static, dynamic and impact loading with high speed capabilities.

- Controlled concrete preparation, casting and curing facility.

- New workshop area and equipment.

Structural Lab testing facilities:

- Controlled-rate uniaxial load testing up to 10MN.

- Bi-axial testing of material and structural specimens.

- High rate uniaxial testing of material and structural specimens by impact and rapid hydraulic systems.

- Controlled cylindrical triaxial testing of materials at up to 700 MPa radial stress.

- Cyclic/fatigue testing of large and small scale components.

- Material creep testing.

- Fixing technology for concrete and masonry structures.

- A range of instrumentation and data acquisition systems.

- Manufacture and testing of material and structural specimens, including beams, column, slabs, connections and test frames.

- Controlled environmental specimen conditioning.

Concrete Durability Lab

The lab houses state-of-the-art facilities for investigating all aspects of concrete degradation. Research aims to develop more effective methods for the design, life assessment and repair of concrete structures and is usually based on establishing a better understanding of deterioration processes.

Concrete Durability Group capabilities include:

- Simulated/accelerated environmental exposure.

- Assessment/monitoring of corrosion and concrete deterioration.

- Measurement of the pore structure and mass transport properties of concrete.

- Advanced micro-structural imaging including optical microscopy, fluorescence microscopy, scanning electron microscopy and laser confocal microscopy and expertise in image analysis and 3D visualisation.

- Compositional analysis of cement and concrete using energy dispersive X-ray spectrometry and micro X-ray fluorescence spectrometry.

- Computer-based modelling of transport and deterioration.

Spotlights - A brief focus on how the laboratory has been used to provide experimental data to validate research findings

- Data validation for predictive methods being applied to the behaviour of coastal armour units

- Study of early-age and long-term cracking in reinforced concrete walls with base restraint and with combined base and end restraint

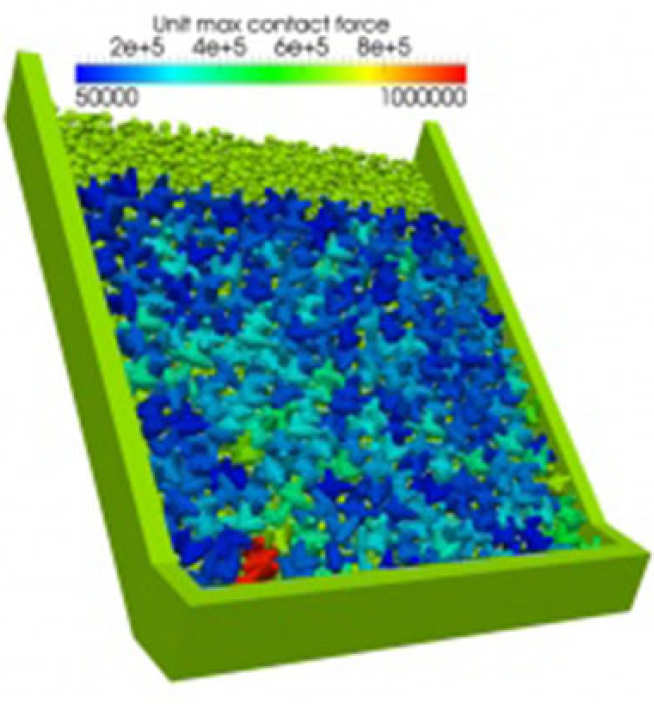

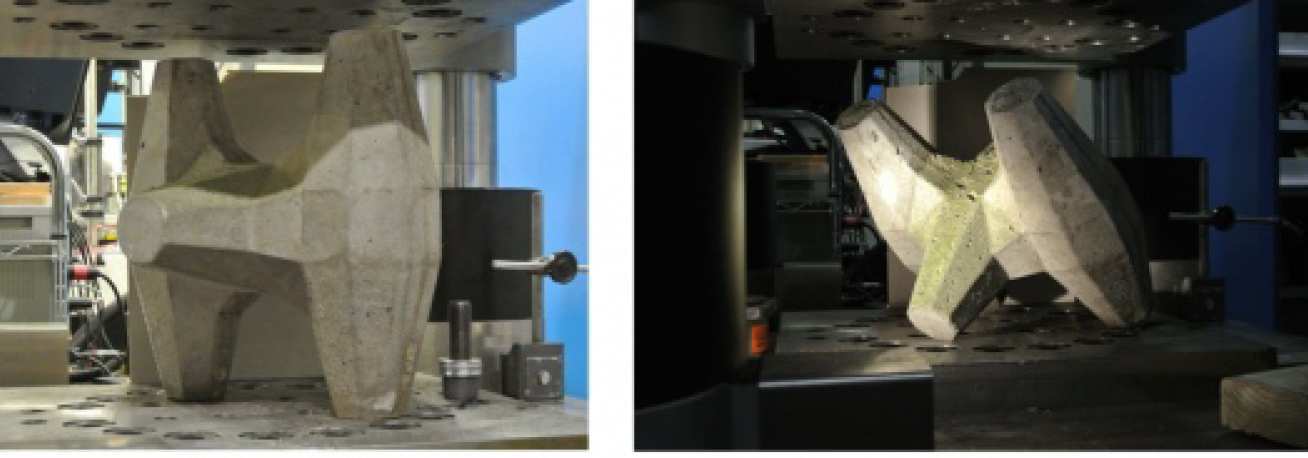

Massive concrete armour units are used extensively around the world in harbour breakwaters and coastal defences. A range of experiments are being carried out in the Structures Laboratory, to support the development and validation of computational methods (in the Department of Earth Science and Engineering http://vgest.net/applications/coastal-engineering/stresses-in-armour-units/) aimed at predicting the behaviour of multi-body systems comprising such units in the loading regimes typically experienced in reality. In-elastic models including plastic and fracture behaviour are being introduced into the computational models.

The real armour units in use today have a range of shapes and are typically 2.5 to 4.5m high, weighing between 15 and 60 tonnes. The laboratory test programme is using scale models (around 1/8 and 1/50). For example, these 350mm high units will be loaded in compression in a 3500KN capacity servo-hydraulic test rig, in both four-point and six-point loading configurations.

Individual “arms” have been cast onto rigid mountings to allow the frictional and damage characteristics of interactions between units to be assessed.

Contacts:

Department of Civil and Environmental Engineering;

- Andy Pullen, Structures Laboratory; a.pullen@imperial.ac.uk

- Professor Bassam Izzuddin, b.izzuddin@imperial.ac.uk

Earth Science and Engineering;

- Dr John-Paul Latham, j.p.latham@imperial.ac.uk

In practice, when casting concrete elements on site, it is difficult, if not impossible, to avoid having any form of restraint whatsoever, which is a potential cause of cracking. Example applications include (but are not limited to) reinforced concrete (RC) walls cast on stiff foundation bases (base restraint) and RC wall panels cast between previous pours on a stiff base (combined edge and end restraints) such as in retaining walls, liquid-retaining tanks and underground structures including tunnels.

Cracking in RC structures is problematic not only because it jeopardises aesthetics and durability but also because it may cause water leakage problems in liquid-resisting structures. Crack widths may, however be controlled by steel reinforcement.

A series of tests are carried out in the Structures Laboratory within the Department of Civil and Environmental Engineering at Imperial College London to investigate parameters affecting cracking and crack widths in walls with base restraint and with a combination of base and end restraints. Tested walls are typically 3.5m long and vary in height between 0.5 and 0.75m. Steel fixing as well as concrete mixing and casting is carried out by qualified laboratory technicians in the Structures Laboratory. Following casting, the RC walls are monitored for cracking during early age thermal contraction and long term shrinkage. In addition, quality control tests such as cube and cylinder strength tests are also carried out within the Structures Laboratory.

Temperatures are constantly monitored using thermocouples cast within the concrete. Transducers monitor horizontal and vertical wall displacements whereas DEMEC strain gauges and electric strain gauges are used to monitor compressive and tensile strains in the RC wall and restraining steel beam. Cracks are monitored and crack widths measured using a crack width microscope.

Preparation for casting the ends of a wall with combined restraint

- PhD candidate: Marianna Micallef

- Laboratory technician: Leslie T. Clark

- Supervisors: Dr Robert L. Vollum; Professor Bassam A. Izzuddin

- Project funding: Laing O’Rourke

Contact Structures

Structures

Civil and Environmental Engineering

Skempton Building

Imperial College London

South Kensington Campus

London, SW7 2AZ

Telephone:

+44(0) 207 594 6040

Email: r.bello@imperial.ac.uk

Alternatively view our people lists

We are located in the Skempton Building (building number 27 on the South Kensington Campus Map). How to find us