Helium supply

We use helium to prevent oxidation of the mirrors that focus the X-ray beam. As continuous extended exposure of the optics to intense radiation in air may degrade performance, make sure that helium is always flowing. The two indicators near the separation wall on the X-ray deck should read about 20.

Replacing a helium cylinder

To the left of the facility door are spare helium cylinders. At least one should always be full. Unused cylinders can be recognized by a pink plastic seal across the outlet.

The following instructions for swapping cylinders are taken from the Matheson Guide to Regulators. A printed copy can be found by the helium cylinders.

- Close the valve of the empty cylinder, remove the regulator and swap the empty cylinder for a full one. Secure the cylinder against the wall. Be careful with cables on the floor.

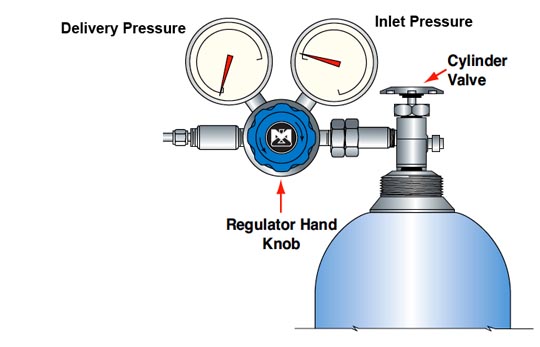

- Close the regulator by rotating the hand knob in a counterclockwise direction.

- Break the seal on the cylinder by twisting and reattach the regulator.

- Slowly open the gas cylinder valve. Check that the inlet pressure reads about 200 bar. Low cylinder pressure may indicate a leaking valve, which can be a serious safety issue.

- Open the cylinder valve completely.

- Adjust delivery pressure to 10 psi (0.7 bar) using the regulator hand knob.

- After flow is established, the set delivery pressure may decrease slightly. Check delivery pressure and make any necessary adjustments.

- Make sure that the flow indicators by the separation wall on the X-ray deck read about 20. If necessary, adjust the flow using the black knobs underneath the indicators.