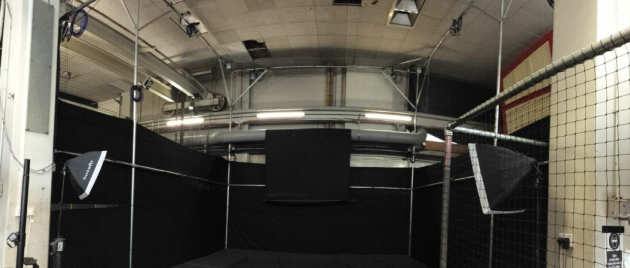

Vicon Flight ArenaFlight Arena

A large enclosed 10x6.2x5.5m flight arena, equipped with 16 Vicon T40 tracking cameras, capable of tracking multiple flying objects in 6 degrees of freedom, with millimetre accuracy. Tracking data can be used for closed loop control of vehicles.

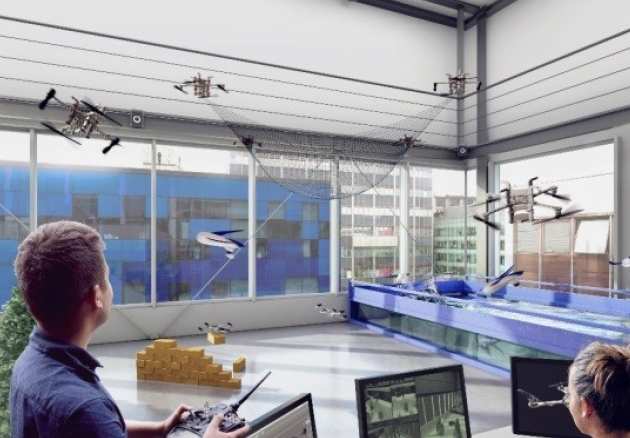

New Flight Arena ready in 2017

The new drone testing facility, the £1.25m Brahmal Vasudevan Aerial Robotics Lab, will allow development and testing of next-generation flying robots. The facility is currently under construction and is due to be completed in Summer 2017

Microthruster Lab

Microthruster Lab

Flight test lab with full fume extraction (air replaced 15 times/hour),DPSS laser allowing for the safe indoor testing of combustible fuels and rocket engines for micro aerial vehicles. The lab is equipped with a 8-camera Optitrack system for vehicle tracking, a water tank for aerial-aquatic tests, and a protected observation area.

Hydrodynamics Lab

- 9m Water Flume

- 0.6m x 0.7m

- Flow speed 1m/s

- Carriage speed 2.8m/s

- Ti 1%

Aerodynamics Lab

- 3 High Speed and 2 low speed PIV systems (Dantec and LaVision)

- 2 Digital LDA systems (Dantec)

- 5 Multi channel pressure scanning systems

- Reconfigurable multi-axis traverse assemblies

- Range of high and low speed digital cameras

- New high-precision 3-axis traverse systems for the new wind tunnels.

- 5 ATI 6-component Digital force balances.

- Streamline and Mini-CTA hot wire anemometry

- High precision 3D vibrometer

- External 3-component wind tunnel force balance

Flight Simulator

Newly designed Flight Simulator Laboratory for aircraft flight modes and performance research & teaching, with flexible engineering simulator capabilities, 6-dof full motion platform, modern flight and control development workstations.

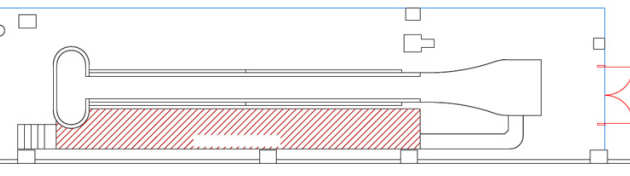

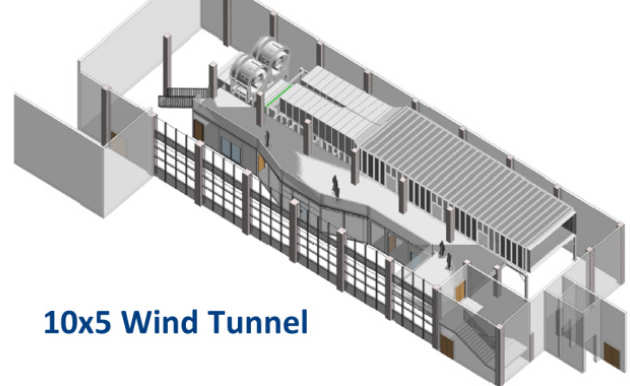

Wind Tunnels

The Aeronautics department has a comprehensive series of wind tunnels, covering speeds from a few metres per second to Mach 9. Wind tunnels are unique facility to study UAVs in extreme weather conditions allowing the development of high-performance aerial robots that can operate in real world outdoor environments. Flow studies in shear, Turbulence studies, Road Vehicle Aero, Aircraft Aero, Environmental testing, Wind Turbine testing, Cross-wind Flight Arena.

Novel Pressure – Vacuum systemSupersonic Wind tunnel

- Operates between M0.5 to M5

- Optimised for Shockwave/boundary layer interaction experiments

- Storage pressure of 40bar

- Max settling chamber pressure 5bar

- Temperature range 20 to 500 deg.C

- Run time 10 sec (typical)

- Recharge time 20 mins

Structures, Composites and other Testing Labs

Laser Micromachining System

Objet 350 Connex Rapid Prototyping Machine

SCS Labcoater Parylene Deposition System

Thermoforming Equipment

FDM Rapid Protyping Systems

Faro 3D ScanArm

CO2 Laser Cutter

Instron test machines

High Precision Water Jet Cutting Machine

Scanning Electron Microscope - Hitachi S-3700 Variable Pressure SEM

C-Scan System

Hypaject MK III resin injection machine

XPERT 80 Digital Cabinet X-ray System

Automated Layup Cutter

DSC (Differential scanning calorimeter)

Dynamic Mechanical Thermal Analysis (DMTA)

Heated vacuum table

Composites repair kit: Leslie & Anita

Contact us

Prof. Mirko Kovac

Department of Aeronautics

Office hours Thursday 2-3pm

Email: m.kovac@imperial.ac.uk

Tel: +44 (0)207 594 5063

Twitter

@AerialRobotics

@MKovacRobotics

See Our location (Google maps)

See South Kensington Campus map