New CO2 separating membranes could make carbon capture more efficient

by Sara West

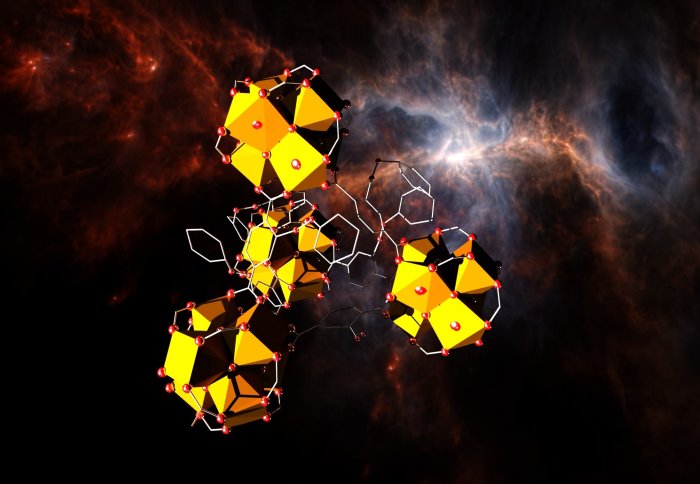

Cover image for Prasetya et al., J. Mater. Chem. A, (2018)

The composite membrane can make separation, storage and release of carbon dioxide easier, meaning more can be extracted from power plant emissions.

The membrane, developed by researchers at Imperial College London and published today in Journal of Materials Chemistry A, performs better than traditional materials when used for carbon dioxide (CO2) capture from power plants.

Carbon capture and storage (CCS) is one of the key technologies for reducing CO2 emissions from power plants, by preventing them from reaching the atmosphere. This CO2 can then be passed on to industries that need it.

Recent CO2 shortages brought several industries, including food and drink, to a standstill, demonstrating the importance of ensuring year-round supplies. CCS is also widely recognised as playing a vital role in supporting the UK to meet its climate change goals.

To capture the CO2, it first has to be separated from the other gases emitted by power plants, and this is where the new membrane comes in.

The membrane is made of a UV-responsive material and a polymer, which can absorb and release CO2 with the application of UV light. This is a less energy-intensive way to release the CO2, which would otherwise require the application of heat or pressure.

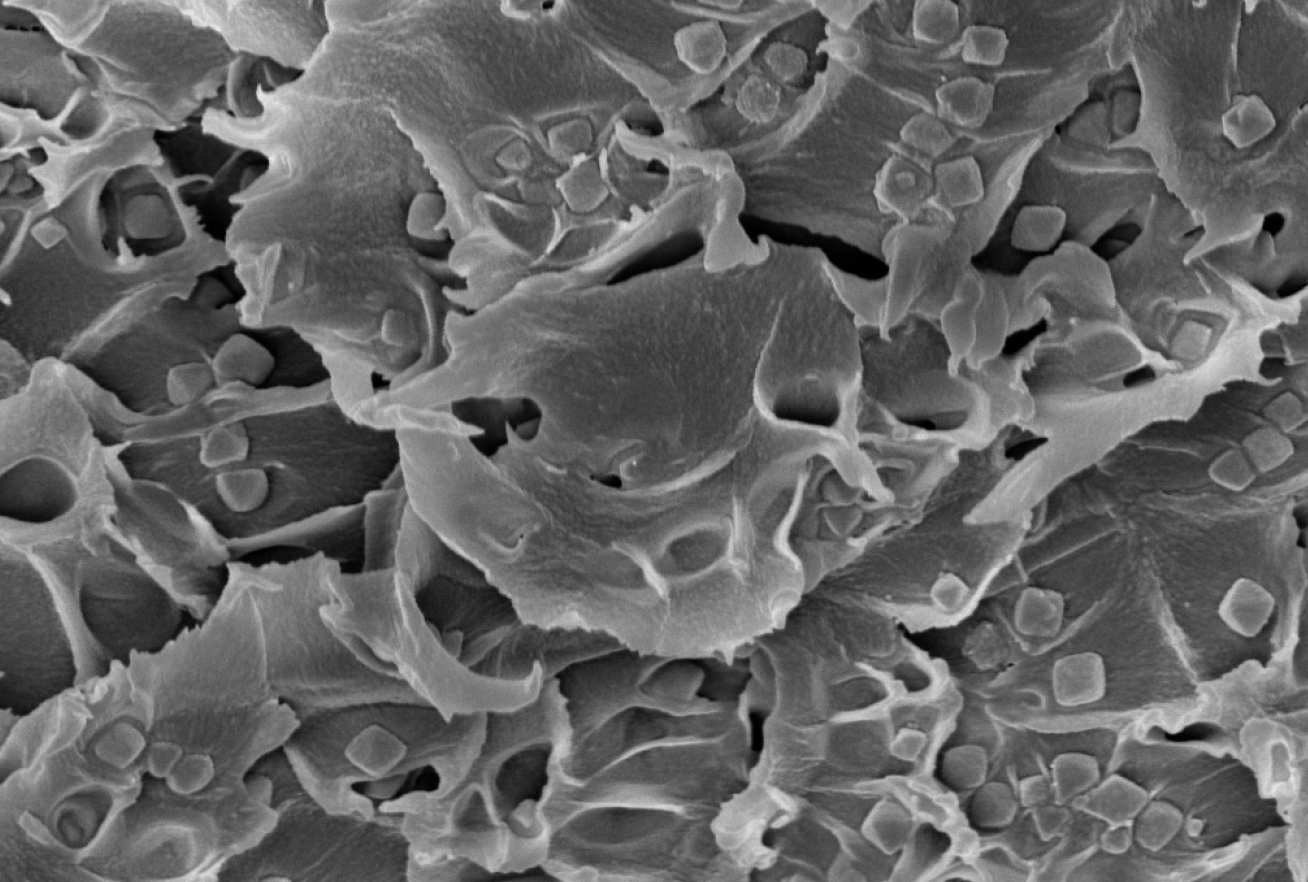

The composite material, developed by PhD student Nicholaus Prasetya and Dr Bradley Ladewig from the Department of Chemical Engineering at Imperial is the first of its kind. Initial research shows its ability to effectively separate carbon dioxide and nitrogen in post-combustion processes; for example treating flue gas from a power plant.

Dr Ladewig said: “Our previous work already showed that photo-responsive materials can be used as carbon dioxide sorbents, but this is really innovative - we have shown that it’s possible to make photo-responsive carbon dioxide separation membranes.”

This research has opened the door for further exploration of innovative applications for UV-responsive materials in the carbon capture and post-combustion stage of carbon capture and storage (CCS) processes. When CO2 is filtered more efficiently in these processes, the result is that less CO2 is released into the atmosphere and more can be stored for further use in other industries that have a demand for it.

As an emerging area of research, further experimentation is required, but initial results are promising. An important element of the carbon capture and storage process, this work could lead to a new generation of more efficient, longer lasting, and cheaper to develop membranes.

A new and highly robust light-responsive Azo-UiO-66 for highly selective and low energy post-combustion CO2 capture and its application in a mixed matrix membrane for CO2/N2 separation, Journal of Materials Chemistry A (2018), is available at https://dx.doi.org/10.1039/C8TA03553A

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Sara West

Communications Division