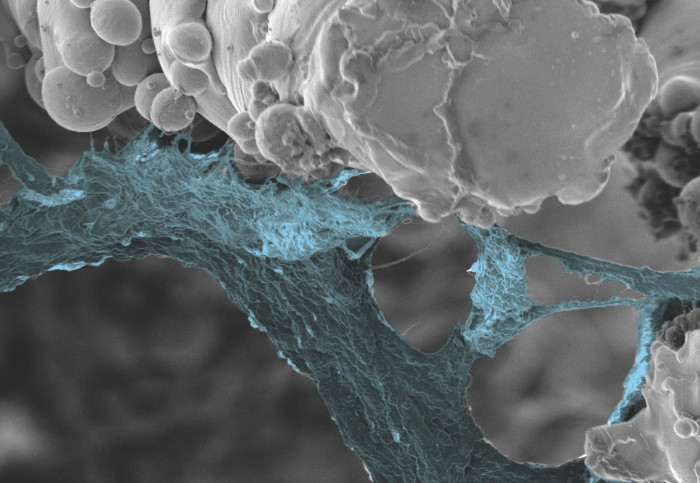

Bone, in blue, grows into an OSSTEC implant, forming a natural bond.

Imperial startup OSSTEC has raised £1.2 million to take its system of smart bone implants into clinical trials.

Not all knee replacements are equal. For an elderly patient, the goal tends to be pain reduction and restoration of mobility, while for patients under 65 the emphasis is on a return to active life. Providing these younger patients with implants that perform well and last longer is the goal of Imperial startup OSSTEC, which has just closed a £1.2 million funding round.

It is increasingly common for people under the age of 65 to have knee replacement surgery, rather than wait for the damage to become more severe in later life. But this changes the demands placed on the implants.

“A younger patient has about a 35% chance of implant failure during their lifetime, and the leading cause of failure is loss of fixation between the bone and the implant,” says Dr Max Munford, co-founder and Chief Executive of OSSTEC. “New technologies mean we can do much more for younger patients and provide a much more innovative solution than the existing, solid metal implants, and that is what we are doing here at OSSTEC.”

OSSTEC not only has an advanced technological solution, but also a credible plan to build a company around it. Dr James Groves Imperial College Enterprise Fund

The funding round that closed this week includes a contribution from the Imperial College Enterprise Fund, which invests in early-stage scientific and technology companies as they spin-out of Imperial.

“What grabbed my attention as an investor is that OSSTEC not only has an advanced technological solution, but also a credible plan to build a company around it and realise the innovation all the way from the 3D-printer to the operating theatre,” says Dr James Groves, the fund’s Investment Manager.

Living materials

Part of the problem with solid implants is that they do not behave in the same way as bone, which is a porous, living material that reacts dynamically to the strains placed upon it. Solid implants stifle bone’s natural healing response to damage, leading to problems over time.

“Rather than using solid materials, which are fairly alien in the body, we are using 3D printing technology to make titanium structures that replicate how bone naturally works,” Dr Munford says. “We are emulating how bone naturally heals itself, how bone naturally grows, and how it is maintained in the long-term.”

Being porous also means a better bond can be created between the implant and the bone. “Just like a tree grows roots into the ground, bone grows roots into the implant, so rather than relying on cements to fix an implant to the bone, you have a biologic fixation.”

The technology that OSSTEC is developing is based on research carried out in the Department of Mechanical Engineering on both the material’s structure and how it might be turned into implants using 3D printing. This is a technique that lays down thin layers of a material in a precise pattern, gradually building them up to produce an object.

“The design of the material structure is innovative, but the big step is how we turn that into a software platform to tell the 3D printer what to do,” he says.

Entrepreneurial intent

Dr Munford joined the research project as a PhD student in 2018, after short periods working in medical device consulting and surgical robotics. “In those roles I felt very detached from the impact and the value that was being provided, which led me towards my passion and dream of driving a venture forward,” he says. “I saw the PhD as a really good way to get involved and build something from the ground up.”

OSSTEC was formed through participation in the Venture Catalyst Challenge, an entrepreneurial competition for Imperial students and alumni, and the MedTech SuperConnector programme, which supports the early-stage development of innovative medical technologies.

In one building we can design, 3D-print and test implants, which is quite unique. Dr Max Munford OSSTEC

“The MedTech SuperConnector came with a small amount of funding, which was a huge amount of funding for us at the time, and that kickstarted the commercialisation,” Dr Munford recalls. “It enabled us to think very seriously about the process, and gave me the skills to map out the route to the market, how might we raise funds, and what goes into running the company.”

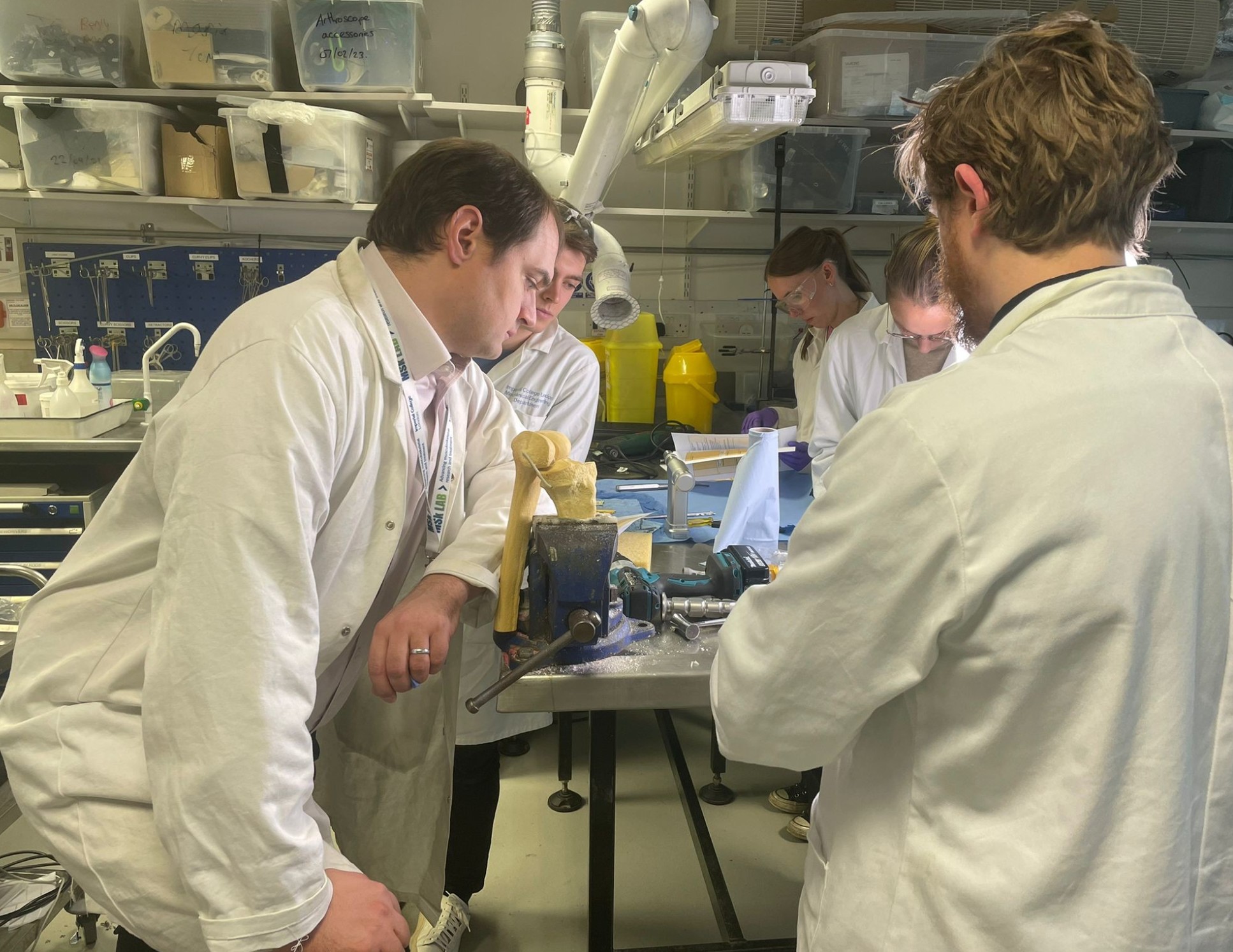

Last year Dr Munford was awarded a Royal Academy of Engineering Enterprise Fellowship to support the further development of OSSTEC within the Department, which remains the ideal environment. “In one building we can design, 3D-print and test implants, which is quite unique.”

Looking forward to surgery

Work is currently underway preparing for the first use of the implants in patients. “We have animal data to show that the structure works, that it heals bone better than conventional implants, and stimulates bone in-growth. And we have human cadaveric data to show that the transition from animal model to humans would hold.”

The next step is to refine the prototype implants and make sure they can handle the different loads and stresses that they will experience once fitted. “Now we are pulling all of our research from the past eight years into the real world,” Dr Munford says.

The present funding round, together with an Innovate UK grant that OSSTEC received in 2022, will allow the company to carry out the regulatory testing and development needed to begin clinical studies. “So, it’s finalising development, preparing to get to market, and establishing the quality management system.”

Having surgeons that champion our technology translates into demand and will attract the attention of potential commercial partners. Dr Max Munford OSSTEC

An important part of this process is talking to the medical profession about the potential of these new implants. “Listening to surgeons, being aware of what they need, and getting them involved in the process is absolutely crucial,” says Dr Munford. “Having surgeons that champion our technology translates into demand and will attract the attention of potential commercial partners.”

The Imperial College Enterprise Fund was the first to make a commitment to OSSTEC, providing a vote of confidence to enable Dr Munford to engage further investors and secure the remainder of the round. This was led by SFC and OION Growth Fund.

“Through a combination of our introductions to angel groups and Max’s tenacity, OSSTEC is now in a financial position to drive the company forwards towards hitting critical milestones,” says Dr Groves. “This is exactly what the ICEF should be doing, investing in early-stage high-tech companies from Imperial to set them on a path to generate both impact and a strong financial return.”

Supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ian Mundell

Enterprise