Machine learning puts yeast on a fast track for efficient protein production

by Ian Mundell

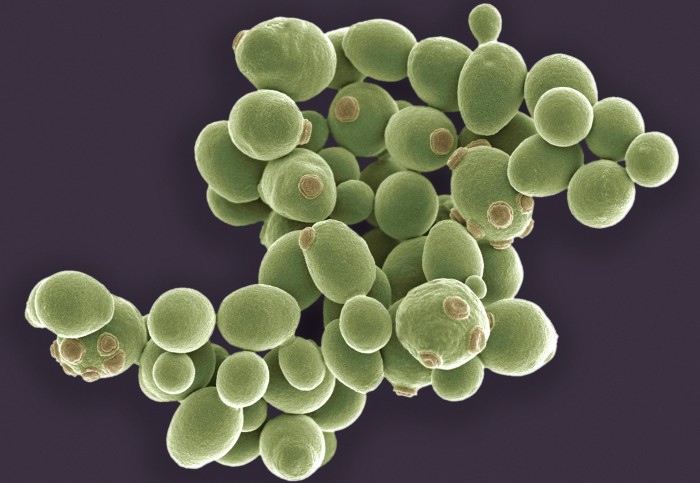

Yeast cells can be programmed to produce proteins

A startup with its roots at Imperial is using artificial intelligence to optimise yeast strains and so unlock the potential of precision fermentation.

Precision fermentation, which uses genetically engineered yeasts and other microorganisms to custom-make a wide range of molecules, is attracting a lot of attention. Startups and established companies alike are looking for ways to harness the technology and bring new products to the market, from pharmaceuticals and foodstuffs through to new materials. Meanwhile, high-profile commentators such as George Monbiot have seized upon the method’s potential to revolutionise food production.

(Getty Images)

Eden Bio, a startup with its roots at Imperial, is part of this trend. Based at Scale Space, in the burgeoning White City Innovation District, it aims to help precision fermentation companies working in a range of product areas realise the technology’s full potential.

“There has been a rise in the number of new companies trying to develop low-value products via precision fermentation, and they need a very high yield to make a strain commercially viable,” explains Dr Chris Reynolds, Eden Bio’s founder and chief executive. “The traditional process is not going to cut it for those strains, which is where we come in.”

Synthetic biologists already know there are a number of changes in the genetic make-up of yeasts that will make them more efficient at producing new substances. Deciding which changes will work best for a given substance is largely a matter of trial and error, however, and testing all possible combinations of changes would take so long that it is practically impossible.

Eden Bio offers a service based on machine learning that cuts through this difficulty for protein production. The first step is to carry out tests to see if yeast can be configured to produce the desired protein at all. “Even if it’s just nanograms of protein per microlitre, then our machine learning can go into action to start improving the strain and find interesting edits,” says Dr Rachel Shaw, Eden Bio’s chief operating officer.

Tweak, test, repeat

This process involves a combination of lab work and bioinformatics. The machine-learning system recommends a series of edits to the microorganism genome, which are then carried out using high-throughput genetic engineering. These results of the engineering are then fed back into the machine-learning system, which then recommends combinations of edits to be tested.

“We test a thousand edits per round, getting the yield as high as we can before sending the developed strain to our customer,” says Dr Shaw.

As time goes by, the system should become more expert. “The more strains we work on, the greater the data set our machine learning is guided by, and therefore the greater our ability to improve yield and help our customers.”

At present, Eden Bio is focusing on genetic changes that affect yeast’s ability to secrete proteins, but in the long run it wants to expand to the production of lipids and other biological products. “Our aim is to disrupt the whole industry,” says Dr Reynolds.

Dairy inspiration

Dr Reynolds’ entrepreneurial drive has its roots in an academic experience that had a strong practical dimension. He first came to Imperial for a bioinformatics PhD in the Department of Life Sciences, on a studentship part-funded by Equinox Pharma, an Imperial startup then based in the Imperial Incubator.

“This meant that my PhD was focused on direct value generation,” he recalls. “I gained experience of building partnerships and providing customers with a service. Then, in my synthetic biology postdoctoral work, a significant focus of the department was on commercial application and bringing engineering principles to science.”

At the beginning of 2020 he used this experience to co-found the company Better Dairy with the entrepreneur Jevan Nagarajah. Its goal is to develop animal-free cheeses using precision fermentation to make the proteins, fats and sugars found in milk. A machine-learning system was conceived to make this possible, and it proved decisive in getting Better Dairy to the point where it could start preparing for its Series A funding round.

The potential of machine learning to improve precision fermentation is vast. Dr Chris Reynolds Eden Bio

At that stage, Dr Reynolds decided he wanted explore the broader potential of machine learning in protein production, rather than apply it in just one sector. So, he stepped down as chief technology officer of Better Dairy, and started Eden Bio at the beginning of 2022 to take the idea further. “I wanted to look at how the machine-learning platform could be applied across more than just cheese, from other foods and biomaterials to industrial enzymes and therapeutics,” he says. “The potential is vast.”

Starting in Scale Space

Finding a home in Scale Space offered Eden Bio several advantages, including the possibility of renting a large laboratory and then subletting to other startups. “It reduces the cost for us now, and means that when we need to expand, we can do so easily without having to move labs,” Dr Shaw says. At present Eden Bio’s lab-mates are Arda Biomaterials, which is developing a vegan leather; FlexSea, which is working on plastic alternatives made from seaweed; and FoodSquared, which is creating vegan food alternatives.

Being able to learn from the broader community of startups at Scale Space has proved beneficial, as have the legal and business training courses provided to its residents. It has also helped Eden Bio arrange internships with Imperial students.

Through the I-HUB, we can trial new equipment and access resources and expertise built up over years. Dr Rachel Shaw Eden Bio

Being close to Imperial’s Translation and Innovation Hub (I-HUB) has been incredibly useful for Eden Bio, especially when it comes to getting them access to specialist equipment.

“There’s only so much you can afford to spend on machinery in the early days of a startup,” Dr Shaw explains. “Through the I-HUB, we can trial new equipment to be sure it’s right for our workflows, and gain access to all the resources and expertise they have built up over the years, which is a real positive for investors.”

Eden Bio has also built on Dr Reynolds’ connections with the synthetic biology community at Imperial. The company’s recent £1 million seed funding round was led by SynBioVen, a specialist venture fund whose board includes Professor Richard Kitney and Professor Paul Freemont, co-founders and co-directors of the SynbiCITE incubator. “The seed round allows us to expand our R&D and validate commercially,” says Dr Reynolds. “We’re already delivering for our first customer, and we’re excited for all the other contracts we’ll be working on over the coming year.”

Main image: Getty Images/Science Photo Library

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ian Mundell

Enterprise