NEW BOOK ALERT! - Data Science in Metal Forming

We are very happy to share the publication of <Data Science in Metal Forming> (ISBN: 978-0-443-29145-6), authored by MFG members, Heli LIU and LiLiang Wang, in collaboration with Elsevier.

💡 Key fact: In the era of AI, data is KING, 70–80% of the effort in AI tool development goes into collecting high-quality data.

This first-of-its-kind book provides a practical framework to collect, visualise, and analyse metal forming data, enabling smarter design, more efficient production, and innovative applications. Highlights:

✔️ Data collection: Practical methods for capturing high-quality metal forming data

✔️ Data processing: Strategies processing for information absent or fragmental metal forming datasets

✔️ Data application: Turning metal forming data into tangible design & manufacturing impact

🤝 Data packages for training AI tools are available upon reasonable request. You are warmly invited to contribute your own data to enrich this shared resource. For inquiries, please contact Heli LIU.

2025

- Have you seen the ‘DNA’ of manufacturing processes?

- Celebrate Research Excellence in the Metal Forming Group

- Ever wonder how digital technology is changing metal forming?

- How to activate ceramic-assisted ion transport in composite solid electrolyte?

- Best Paper Award!

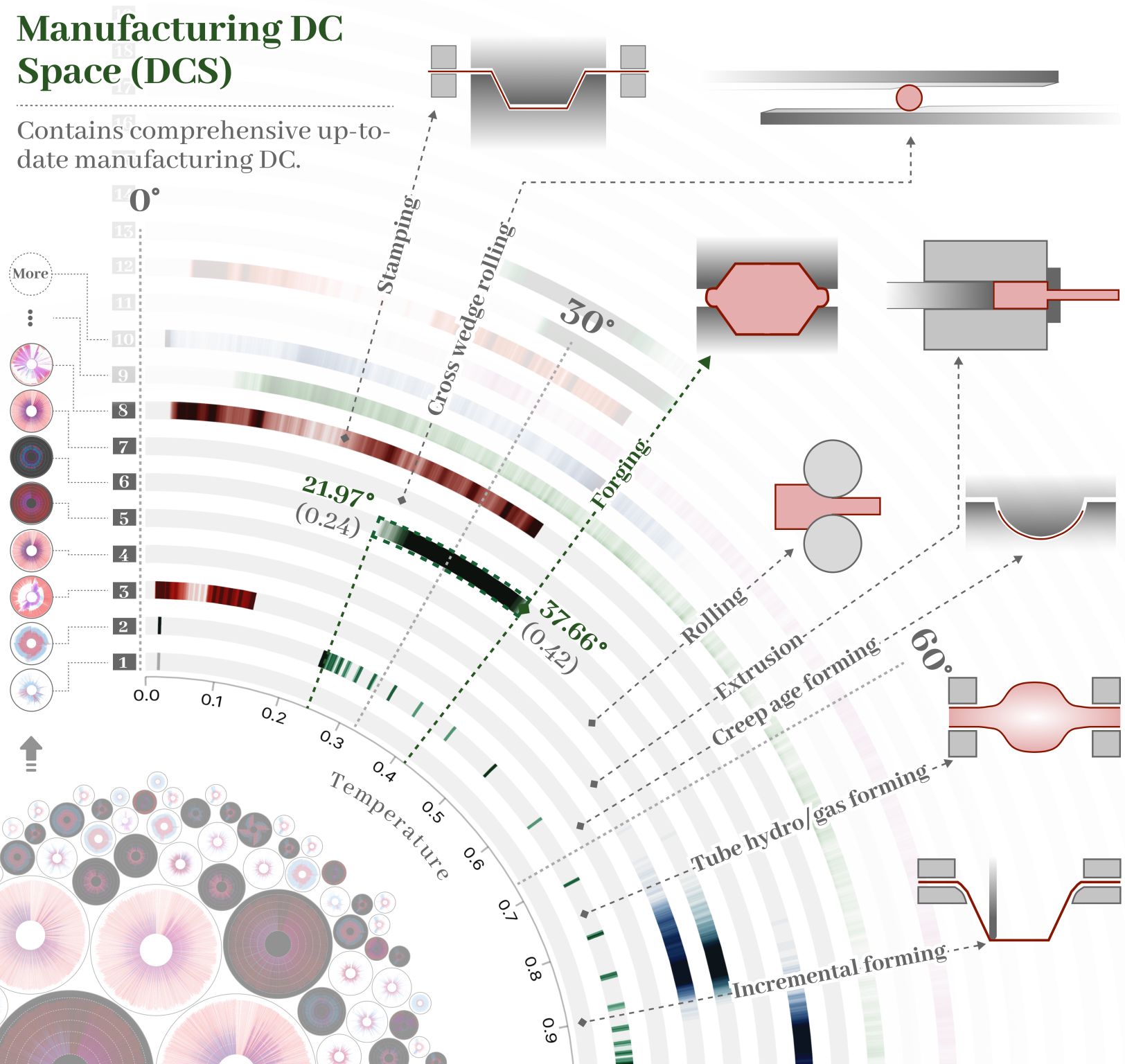

90% of metal products rely on forming processes - yet their data is often information absent and fragmental. Our latest research, published in JMSY, cracks the code!

90% of metal products rely on forming processes - yet their data is often information absent and fragmental. Our latest research, published in JMSY, cracks the code!

Using an information absent data processing framework enabled by Evolutionary Binary algorithm, we achieved:

- Over 90% accuracy in recognising missing features of metal forming processes with sparsely labelled data.

- Mapped the ‘DNA’ of manufacturing processes - digital characteristics (DC) - to trace data origins with over 90% accuracy.

- Paving the way for DC-aided engineering, diagnostics, and DC-aided sustainable manufacturing.

Check the full article here: ‘Genetic exploration’ of metal forming processes through information absent and fragmental data processing - ScienceDirect

We are proud to share that for three consecutive years (2022–2024), PhD students from our group have received the prestigious Unwin Postgraduate Prize for the best PhD thesis in Mechanical Engineering at Imperial College London.

🏆 2022 - Dr. XIAO YANG

Thesis: Lubricant 4.0: Digitally Enhanced Lubricant Development for Metal Forming Applications

Collaborated with global industry leaders, Dr. Yang made fundamental scientific contributions to tribology in metal forming through the development of a novel theoretical framework, interactive friction modelling, and a digitally enhanced lubricant evaluation scheme. These advances enabled the precise selection of lubricants for full-scale hot stamping of lightweight automotive components. Her work resulted in 20+ journal and conference publications - including one in Nature Communications (Editor’s Highlight) - and the deployment of new digital tools on the SmartForming platform.

🏆 2023 - Dr. Wei Wang

Thesis: Microstructural Understanding for Achieving High-quality and Low-cost Solid-state Bonding

Dr. Wang has pioneered research in understanding microstructural evolution and metallurgical bonding formation. His research bridged various domains: interfacial micromechanics in surface physics, solid mechanics in physics, metallurgical bonding in materials science, surface adhesion and tribology. His emergence has been marked by significant recognitions, including the Unwin Postgraduate Prize, Margaret Fishenden Centenary Memorial Prize, and the 1st prize award at the Fusion Manufacturing Challenge 2023. He has made fundamental scientific and technological contributions to bonding technologies as evidenced by over 20 publications in Acta Materialia, JMPS, IJMTM etc.

🏆 2024 - Dr. Heli LIU

Thesis: Data Science in Manufacturing: Unlocking Digital Characteristics of Metal Forming Processes

In collaboration with global industry leaders, Dr. Liu developed a pioneering data science framework for metal forming - akin to decoding the “DNA” of metal forming processes - enabling the extraction of valuable process insights from extremely sparse and fragmental industrial data. His work led to over 30 publications, including Nature Communications (Editor’s Highlight) and Journal of Manufacturing Systems, attracting more than 1,000 citations. He developed over 200 intelligent modules on the SmartForming platform and delivered four invited international talks, including plenary and keynote presentations. Dr. Liu is also authoring a book entitled "Data Science in Metal Forming" (Elsevier, ISBN: 978-0-443-29145-6).

The Unwin Prize is awarded annually to one PhD student for outstanding research. These recognitions reflect the Metal Forming Group’s commitment to academic excellence, impactful collaboration, and the training of future engineering leaders.

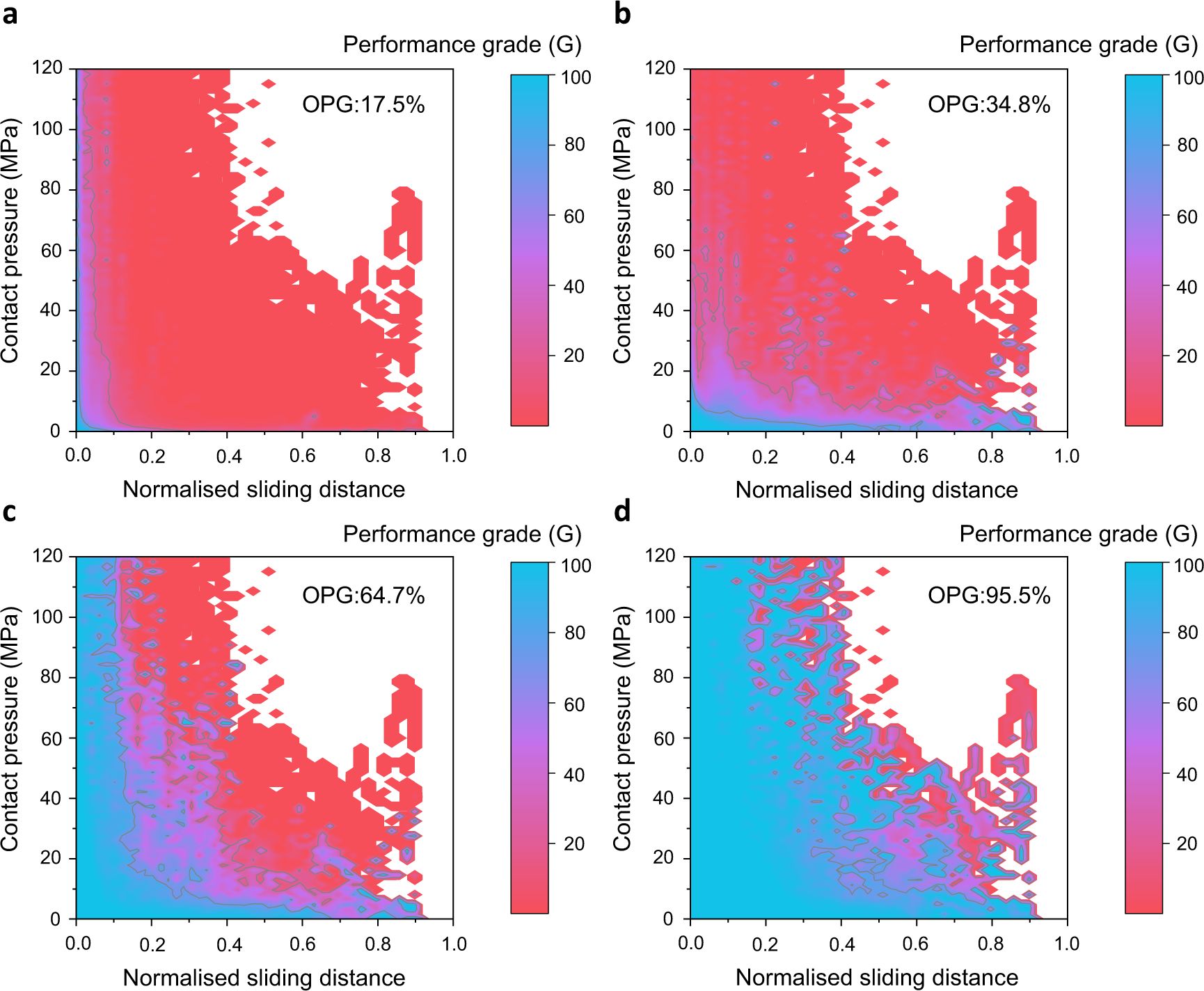

We'd love to share insights from our research, which was selected as one of "The Editors' Highlights" in Nature Communications, Nature Magazine: https://lnkd.in/eDqP968C. Thanks very much for the great efforts from the authors XIAO YANG, Heli LIU, Saksham Dhawan, Denis Politis, JIE ZHANG, Daniele Dini, Lan Hu, Mo M. Gharbi, and LiLiang Wang.

This research combines the implementation of digital characteristics (DC) of the target forming process, data-guided lubricant testing and mechanism-based accurate theoretical modelling, enabling the development of data-centric lubricant limit diagrams (LLDs) and intuitive and quantitative evaluation of the lubricant performance.

Why it matters:

⭐ Enables smart, physics-informed selection of lubricants tailored to the transient contact conditions in hot stamping process.

⭐ Bridges the gap between simulation-driven design and real-world industrial application.

⭐ Paves the way toward AI‑augmented tribology, elevating quality and sustainability in manufacturing.

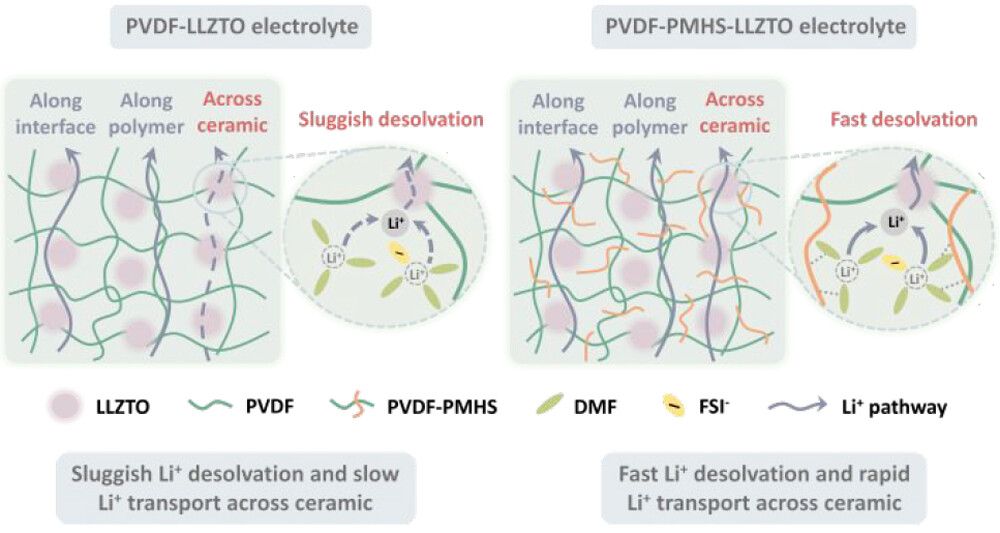

We're excited to share our research published in ACS Energy: https://lnkd.in/e8sr5jYj. This work introduces polymethylhydrosiloxane (PMHS) crosslinking with PVDF to promote Li⁺ desolvation from [Li(DMF)ₓ]⁺ complexes, which are the primary Li⁺ carriers in PVDF-based composite solid electrolytes (CSEs). This unlocks fast ceramic-involved Li⁺ pathways, achieving:

🔹 PMHS-derived stable interfaces

🔹 High ambient ionic conductivity of 7.5×10⁻⁴ S/cm

🔹 Record performance of 11,800 hours for Li|Li symmetric cells

🔹 More than 2,200 cycles at 2C (81.9% retention) for NCM811|Li solid-state cells

Why it matters:

⭐ Offers a novel route to unlock the full potential of ceramic fillers in CSEs

⭐ Breaks conductivity bottlenecks in solvent-coordinated ion transport within CSEs

⭐ Paves the way for next-generation durable solid-state lithium batteries

We are delighted to share that the MFG member Lemeng Z. has received the Springer Nature Best Paper Award for the paper “Experimental and modelling studies of the temperature effects on the interfacial heat transfer coefficient (IHTC) during hot stamping of AA6111 aluminium alloy” at the 22nd International Conference on Manufacturing Research (ICMR) 2025, hosted by the University of Brimingham.

This achievement is a testament to the hard work, innovation, and dedication of the entire research group. We sincerely thank and congratulate all co-authors, Xiaochuan Liu, Heli LIU, Xuheng HAN, Ziyi Chen and LiLiang Wang, for their valuable contributions to this success.

👏 Congratulations once again to Lemeng Z. and the group for this well-deserved recognition!

Vacancies

6 PhD Studentships in Mechanics and Characterisation of Next Generation EAF Recycled Steels for Forming and Welding Applications.

Contact details

For any questions regarding our work, please contact: