New projects developed for remote learning

Staff in the Department of Materials have collaborated to design new practical projects for students.

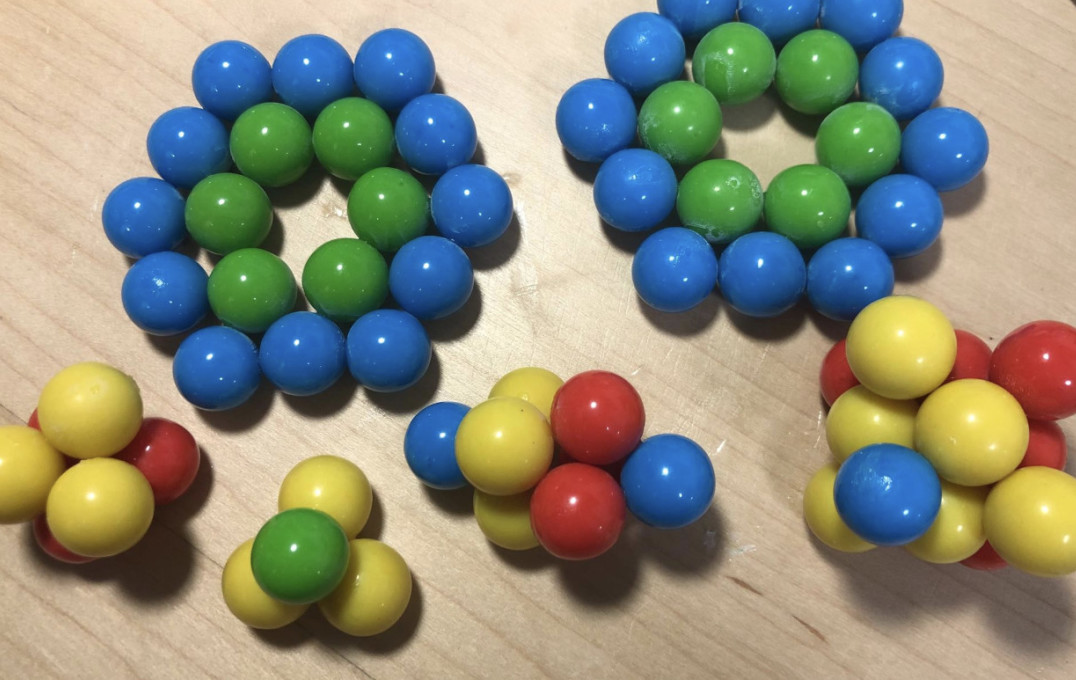

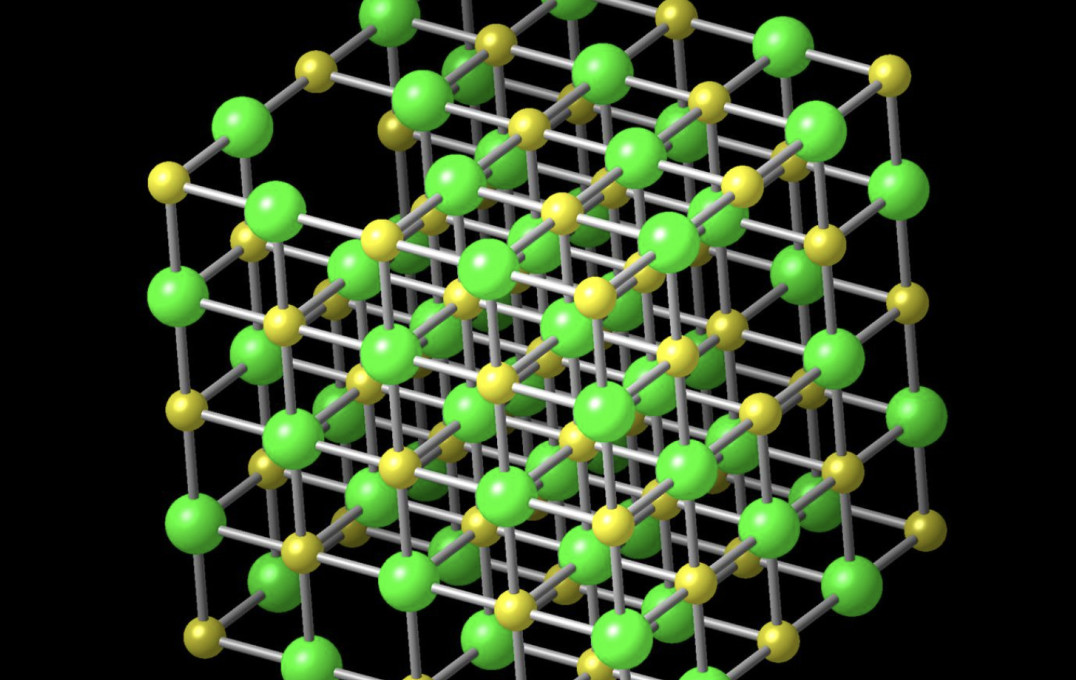

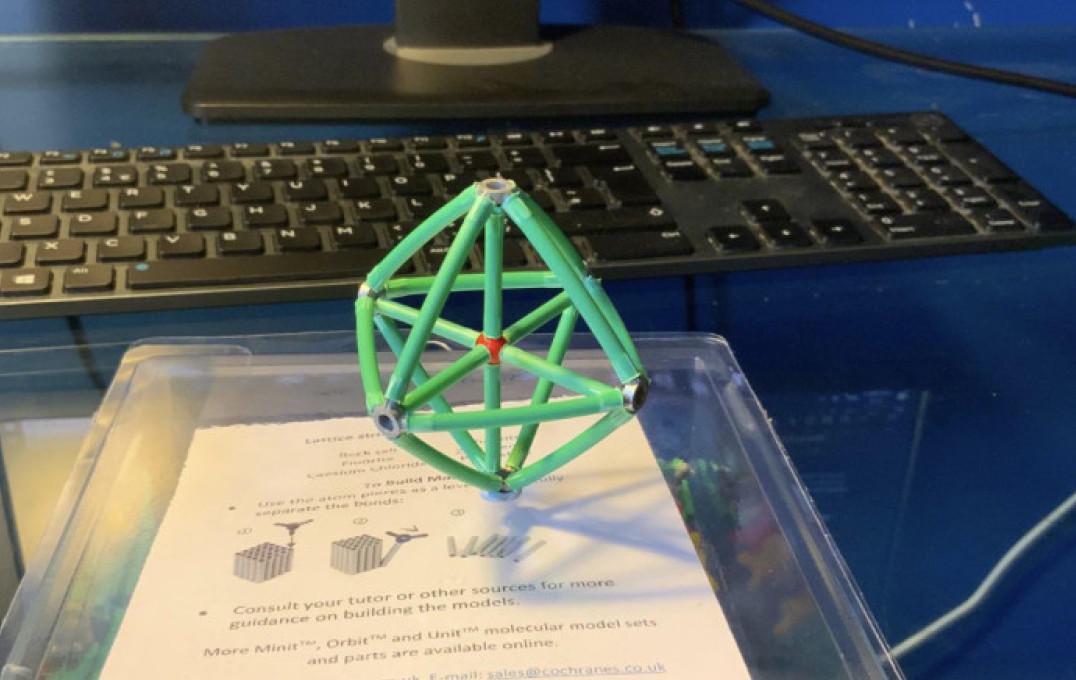

The projects were introduced due to COVID-19 restrictions on campus. The lab kits contained four packets of small plastic balls that could be stuck together to build crystal structures and a specially-designed molecular building system, with the aim to replicate crystallography labs from home.

Bringing the lab to the students

The remote kits allowed students to get hands-on with preparing models of cubic close-packed structures, visualise layer packing in the structure, the packing layers in the unit cell, and the unit cell's location in the overall structure. Students used this equipment to build their structures, replicating virtual structures created in a computer software called Crystalmaker.

First-year undergraduate, Kalea Booth, said "using the new lab kit for a crystallography lab made for an entertaining Thursday afternoon! I’m pleased with my end-product crystal structures. These models will now be kept as a useful aid to the inevitable ‘So what actually is Materials Science?’ questions from various family members!"

Researching beyond the lab

Professor Alexandra Porter led the design of the Biomaterials MEng projects for final-year undergraduate students. She was inspired to include opportunities for practical data collection, drawing on her current research on pollution. The project themes included investigating pollutants in London that can cause health problems, measuring pollution on the Underground and exploring the impact of microplastics on our environment.

Professor Porter explains, "I wanted to design exciting projects that could be applied in the real world. I drew inspiration from Professor Marian Yallop from the University of Bristol, who's an ecologist that we have collaborated with in the past. Her influence led me to study the impact of greenery on pollution, for which we received EPSRC, INHALE and COVAIR funded grants. With restricted access to labs this term, these projects allowed students to collect data in the world around them."

MEng student Jake Sidhu researched airborne pollution in London and investigated whether plants could reduce pollution in cities.

He said, "Getting a handle on the levels of pollution was interesting as there have been studies into the effects of air pollution and COVID transmission, which is particularly important to tackling the pandemic. I was able to go to the sites where we analysed pollution to take photos and videos alongside some notes I made on pollution sources at these locations. I also collected sand in Hyde Park, which will be analysed by the research group in the labs.

Whilst I have not been able to do lab work myself, I am grateful to my supervisor and the research group for all their assistance and support with this project. There have been many challenges, but I have really enjoyed working on a topic that has significant implications for wider society."

New projects ahead

Next term, first-year undergraduate students will engineer a machine from scratch as part of their Design Study module. The aim is to create a rheometer that will calculate the viscosity of different fluids by measuring how much energy it takes to stir the fluid.

Teams of students worldwide will collaborate to design and code the machine, which will then be 3D printed in the Department by research technicians.

Students have currently begun building prototypes using cardboard, touchpads and LED screens. They were also allocated specific roles within each team, similar to positions found in a real-life company. By each having a different role, students will lead different parts of the project, allowing for greater collaboration across virtual spaces.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Kayleigh Brewer

Department of Materials