Aeronautics student wins Airbus competition with novel space manufacturing plant

by Ayesha Khan

Erikas Kymantas led a team to huge success at the Airbus Space competition with a new in-space assembly concept.

Erikas was recently announced winner of the annual Airbus Space competition with a unique manufacturing approach that will help to deliver space projects of the future, including hotels, solar stations, large satellites etc.

The rapid development of space technologies, demand of space missions and physical size of projects is unmet by traditional spacecraft manufacturing, deployment and launch methods. A resolve is to use in-space assembly technologies that can cater to build large space structures and reduce operating costs.

Erikas (below right), and teammate Jake Ward (below left) from the University of Bristol, were challenged to pitch a vision for an in-space assembly project that could achieve reality by 2040.

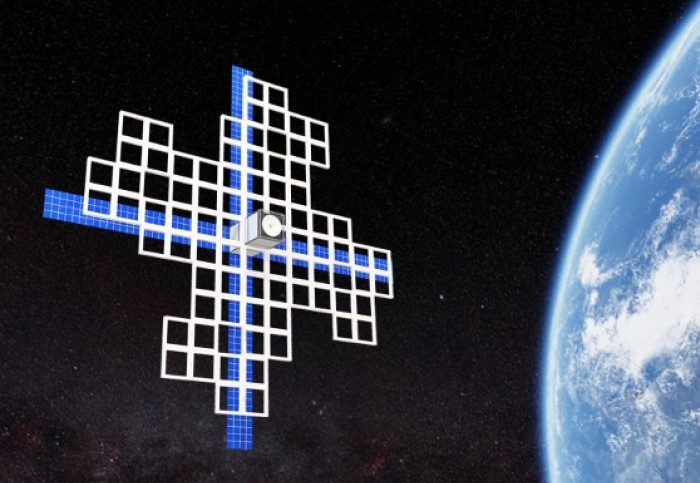

The winning idea came in the form of ‘Astra Lattice’ – a flexible in-space, in-orbit assembly architecture that illustrates an end-to-end solution. The scaffold-like framework is able to receive pre-packaged parts, assemble via autonomous robotic arms and release a complete space structure. The concept would also have the ability to undergo self-maintenance, make real-time smart data-driven decisions and complete on-site verification and learning. Human interaction, from the ground, would be used to complement day-to-day tasks, but would not be relied upon.

The winning idea came in the form of ‘Astra Lattice’ – a flexible in-space, in-orbit assembly architecture that illustrates an end-to-end solution. The scaffold-like framework is able to receive pre-packaged parts, assemble via autonomous robotic arms and release a complete space structure. The concept would also have the ability to undergo self-maintenance, make real-time smart data-driven decisions and complete on-site verification and learning. Human interaction, from the ground, would be used to complement day-to-day tasks, but would not be relied upon.

On the competition, Erikas said: "It was very enjoyable to deeply explore a future space mission that can facilitate the large upcoming spacecraft featuring within an increasingly important space sector to society.

"To develop a winning concept that has direct links to current ESA and NASA calls for research has been an amazing experience and has since led to many interesting conversations and opportunities."

The success of the Astra Lattice idea is also drawn from considerations to not produce space debris, having the ability to complete concurrent assemblies and being fully autonomous in the near future.

The flexibility of the Lattice allows for it to serve a wide customer base, including ambitious projects such as Space Telescopes and space-based Solar Power Stations, commercial companies who would incur lower costs with in-space assembly of spacecraft and the scientific research community in providing a platform for trialling prototypes.

Following the win at Airbus’ Defence and Space Headquarters in Stevenage, Erikas’ team were invited to present their idea at the National Student Space Conference 2023.

The annual Airbus Student Space Competition is open to all UK undergraduates and Master’s students. Students are invited to propose technologies to address current issues using creative thinking and research.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ayesha Khan

Department of Aeronautics