Aeronautics postgraduate students develop new composite Padel racket design

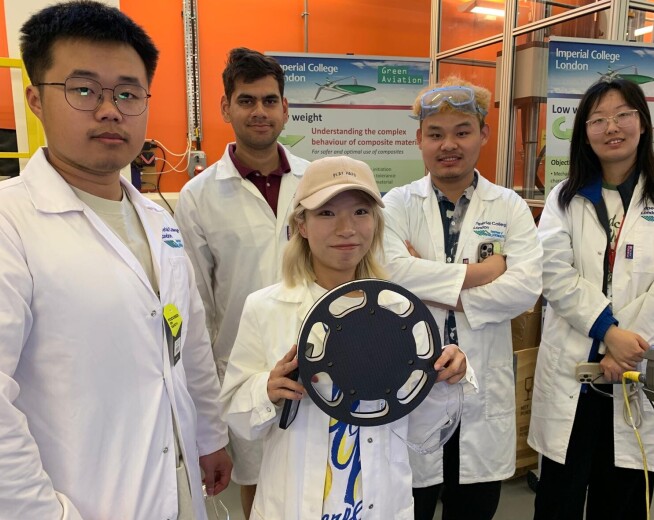

The MSc Advanced Composites students with Padel rackets

Imperial students designed and tested composite Padel rackets, blending advanced analysis, manufacturing, and real-world sports engineering skills.

Teams of MSc Advanced Composites students from the Department of Aeronautics at Imperial College London, under the guidance of Dr. Emiliano Bilotti and supported by graduate teaching assistant Piyapat Jameekornkul, embarked on a unique group project as part of their Composite Engineering Practice module. Their brief was to design, manufacture, and test an innovative Padel racket head, showcasing the possibilities of modern composite materials engineering within the rapidly expanding field of sports equipment design.

At the heart of the project were several important objectives. The students set out to deepen their understanding of why composites are so valuable in advanced engineering contexts, and to master the practical challenges of designing sophisticated composite structures. Alongside theoretical learning, they engaged in hands-on work – using finite element analysis to predict how their designs would perform under real-life stresses and then physically manufacturing prototypes for testing. The world of Padel, a sport experiencing a meteoric rise since its invention in 1969, provided an ideal context for this exploration. Unlike tennis rackets, Padel rackets have a solid, perforated sandwich structure made from composite materials – an engaging technical puzzle for aspiring engineers.

Each group had to design a Padel racket head capable of withstanding a simulated high-speed ball impact as well as a laboratory drop-weight test, without failing in either scenario. At the same time, the rackets needed to maximise the rebound height after impact while minimising the total racket mass. Padel upholds strict international regulations of their rackets, including limits on the sandwich structure’s thickness and the precise area and placement of perforating holes.

Throughout the project, the students navigated a multidisciplinary and iterative engineering process. Choosing the best combination of fibres, matrix, and core materials required careful research and consultation of reputable databases, as well as pragmatic judgment regarding what could be procured and fabricated in practice. The teams used ABAQUS finite element software for detailed modelling and repeatedly refined elements such as face sheet layup, core configuration, and hole patterns in search of the optimal balance between low weight and mechanical resilience. This process was underpinned by the careful selection and application of appropriate failure criteria, ensuring designs could withstand the extreme loading conditions they would encounter during testing.

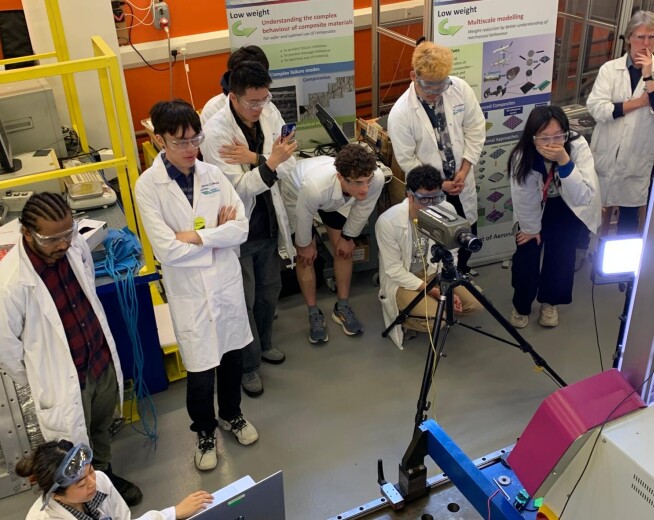

Shifting from design to build, each team worked closely with the technicians in the Composites Suite and Dynamic Fracture and Forming lab (DFF), manufacturing their racket heads using professional grade prepreg laminates, adhesives, and machining processes. The finished rackets were then subjected to a rigorous experimental challenge: a 2.3-kilogram weight was dropped onto the racket in a controlled impact test, and the maximum rebound height – scaled by the racket’s mass – provided an objective measure of each design’s specific power. The accuracy of each group’s computational predictions was put to the test against these experimental results.

The project culminated in a detailed technical report in which students described their design process, documented both numerical and experimental findings, analysed current commercial solutions, and offered recommendations for future development. Assessment considered all aspects of their work, from the rigour of their modelling and quality of manufacture to their capacity for innovation.

For the students involved, this project represented a complete engineering journey: from concept through analysis to manufacture and testing. Not only did it strengthen their technical expertise and teamwork, but it also allowed them to make a tangible contribution to the design of sports equipment in a growing global market. Above all, it provided invaluable experience in bridging the worlds of advanced theory and practical application – preparing them for the complex challenges they will face as future leaders in materials engineering.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Meg Orpwood-Russell

Department of Aeronautics