Business

by Ian Mundell

Three universities join with industry to give graduates the skills and knowledge needed to scale up the benefits of engineering biology.

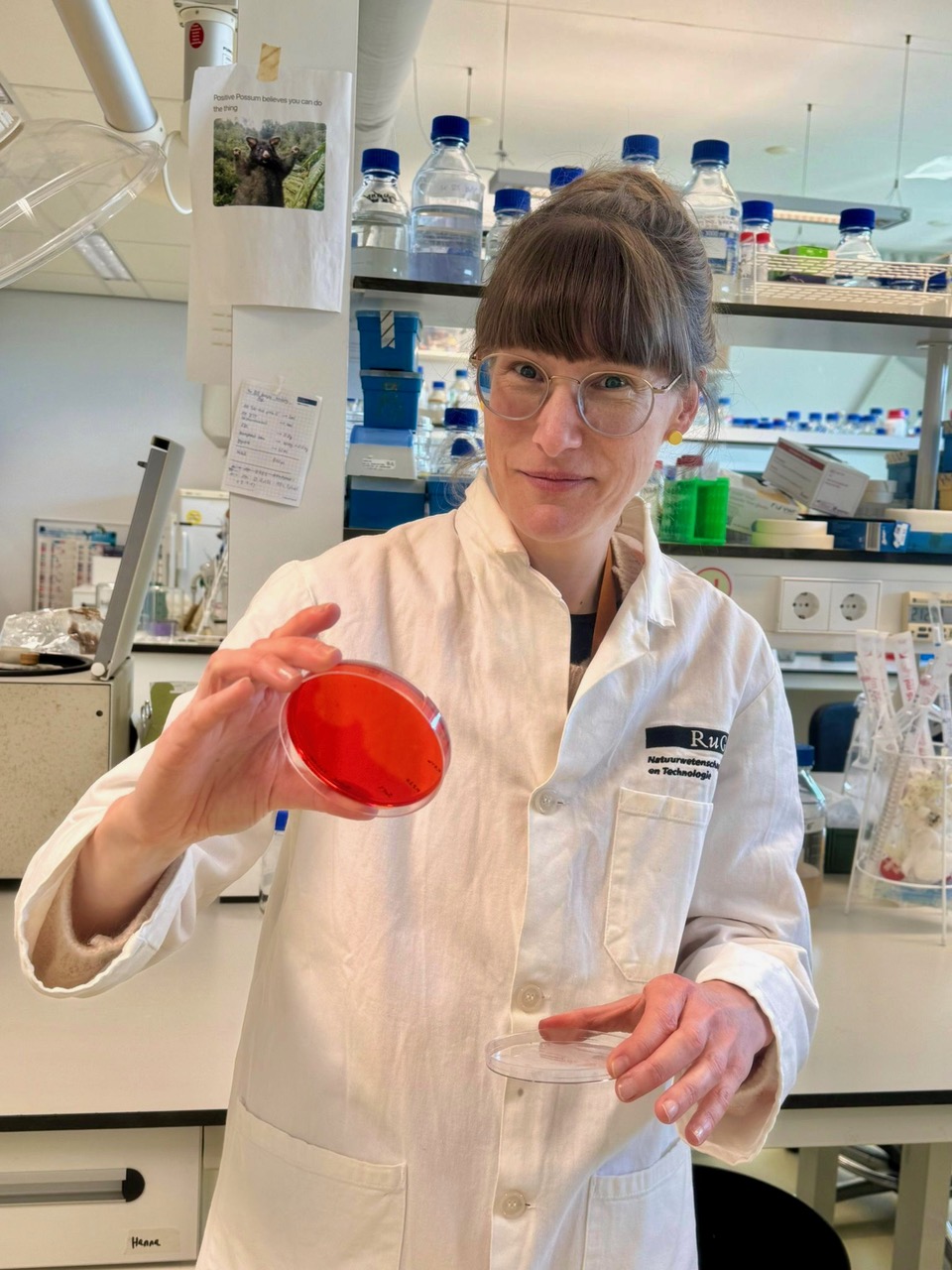

The science of engineering biology allows us to harness the power of microorganisms and mammalian cells to make chemicals, food ingredients and materials in a more sustainable way, or to create entirely novel products. But taking these innovations out of the laboratory and into industrial production is not straightforward.

A new PhD training programme, led by Imperial and BASF, aims to give students the knowledge and skills they need to make this scaling up happen.

At BASF, we're excited to join this PhD training programme in biomanufacturing, equipping future scientists with the skills and mindset to turn ideas into viable industrial solutions. Dr Averina Nicolae Open Innovation Manager, BASF

“In the lab we might be working with one litre or ten litres, whereas industry works with thousands of litres, and there is often a gap in both understanding and training when we have to move from one to the other,” says Dr Sonja Billerbeck of the Department of Bioengineering, who is co-director of the programme. “We are trying to bridge that gap, so that graduates learn what they need to know in order to use these processes at a really large scale.”

Engineering biology is opening the way for the sustainable production of food supplements and ingredients such as dairy proteins, fats and meats. It is supplying novel substances such as fabric dyes that do not rely on petrochemicals for their production, or need to be extracted from plants or insects. And it is producing innovative antimicrobial and antifungal compounds that can be used as biopesticides.

“At BASF, we see biotechnology as a key driver for a more sustainable chemical industry. Its success, however, depends on scalability and cost competitiveness. That’s why we’re excited to join this PhD training programme in biomanufacturing, equipping future scientists with the skills and mindset to turn ideas into viable industrial solutions,” says Dr Averina Nicolae, Open Innovation Manager at BASF. “We offer students real-world challenges, a holistic view of technical, economic, and regulatory factors, and the inspiration to become innovators.”

The programme, called the Sustainable Centre for AI-Leveraged Efficiency in Industrial Biotechnology (SCALE-IB), brings together the complementary expertise of Imperial, University College London (UCL) and Aberystwyth University. It is funded by the Biotechnology and Biological Sciences Research Council (BBSRC), with support from BASF, Bühler and a range of other companies with an interest in engineering biology.

"The commitment of BBSRC to support in-depth knowledge building and excellence in engineering biology for the food system reflects the need for innovation in an economically critical sector,” says Dr Ian Robert, Bühler’s Chief Technology Officer.

These companies, from multinationals to startups, will provide expertise and resources for the training programme, and offer students placements so that they can get hands-on experience of biomanufacturing at scale. This includes sourcing and handling the feedstock on which the cells or microorganisms feed, the configuration of fermenters and other processes to support their growth, through to extracting and refining the final products.

“We have partners along this whole biomanufacturing chain, so we can train students in every aspect of that process,” says Dr Billerbeck. “In this way they can develop the systems thinking they need, so that when they engineer their cells and design their processes, they already know what they are aiming for in terms of the product, how it will be produced and how it will be regulated.”

“Scaling innovations from the lab to industrial reality is a complex and challenging process,” says Dr Darren Budd, Managing Director, BASF plc. “Partnering with leading universities such as Imperial, UCL and Aberystwyth allows us to bring together brilliant minds but most importantly align research with real-world processes and requirements from the start. These kinds of collaborations are crucial for bridging the gap between the discovery and the deployment of new technologies.”

The three universities delivering the training programme have complementary expertise when it comes to engineering biology and a history of collaboration in the discipline.

Imperial has extensive expertise in engineering biology and AI, with a strong focus on developing alternative food products at the UKRI Microbial Food Hub and the Bezos Centre for Sustainable Protein. Spanning seven academic departments, this centre aims to advance research into precision fermentation, cultivated meat, bioprocessing and automation, nutrition, and AI and machine learning.

The UCL Department of Biochemical Engineering has expertise in process engineering that will underpin the industrial application of fermentation and bioconversion technologies, specifically, at the Manufacturing Futures Lab at UCL East.

Meanwhile, the Institute of Biological, Environmental and Rural Sciences at Aberystwyth will lead on technical training and equality, diversity and inclusion matters, and develop students’ expertise in biotechnology scale-up in its pilot-scale biorefinery. Co-located with Aberinnovation, a BBSRC-supported innovation hub, the institute can also draw on AI expertise from the Department of Computer Science.

Both UCL and Aberystwyth University participate in the Bezos Centre, operating one of its national ‘spokes’ through the EPSRC Cellular Agriculture Manufacturing Hub.

The programme is aimed at graduates with a range of backgrounds, from the life sciences to chemistry, food science, and AI and data science, but also business and regulation. “We want our cohorts to have diverse expertise, for peer learning, and we have different types of supervisors who can take on these students and guide their projects, ideally in a highly collaborative fashion,” says Dr Billerbeck.

The PhD projects will be co-developed by the leading industry partners together with the participating universities, and it is anticipated that more companies will get involved to co-create and co-fund projects in due course. Projects can also be put forward by enterprising students.

Those who complete the training will be well-placed to move into industry, where there is an urgent need for people with engineering biology and scale-up skills. “We currently don’t produce graduates who can immediately step into key roles in a company like BASF, for example, to take on critical scale-up projects,” says Dr Billerbeck.

Another likely career path is in entrepreneurship and startups. “Many startups are good at reaching technology readiness levels of four or five, where they can produce something at 10 litres,” Dr Billerbeck says. “But when they need to move forward and produce more in order to become economically viable, there is also a skills or knowledge gap about how to approach this scaling.”

Other options include working on regulation, which is particularly relevant for biomanufactured food products and ingredients, or continuing in academia or education.

The training programme will begin recruiting in December, with a total of 28 PhDs likely to be offered over the three years of the programme. These numbers may grow as further industrial partners are brought on board to co-create and co-fund projects.

Main image: Monty Rakusen/Getty Images

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Administration/Non-faculty departments

Engineering

Health

Imperial Global

Health

Health

Cross-faculty

Engineering

Discover more Imperial News

Search all articlesDiscover more Imperial News

Search all articles