Drop and Plug formation in angled Microfluidic Junctions

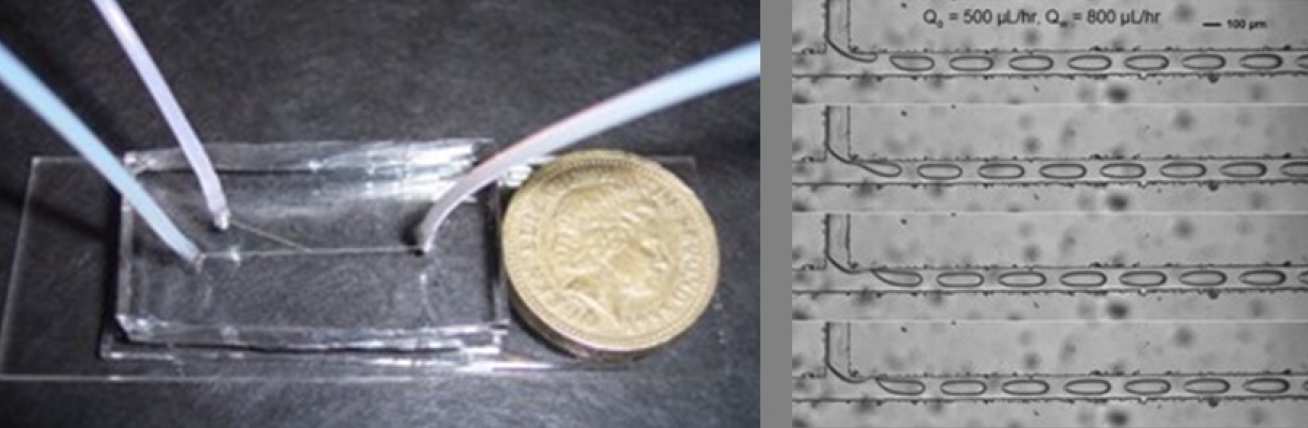

Microfluidics enables very precise handling of small volumes of fluid, and it involves flows in micrometric-scale channels. Those flows are characterised by low Reynolds number, Capillary numbers and significant boundary effects. There is an increasing demand for microscale devices allowing very precise control of drop and plug formation, useful for chemical analysis, microreactors, emulsion polymerisations, encapsulations... A very widespread geometry used to achieve this goal is the T-junction configuration; despite its apparent simplicity, the break-up processes in such geometries are just being deeply studied and explained.

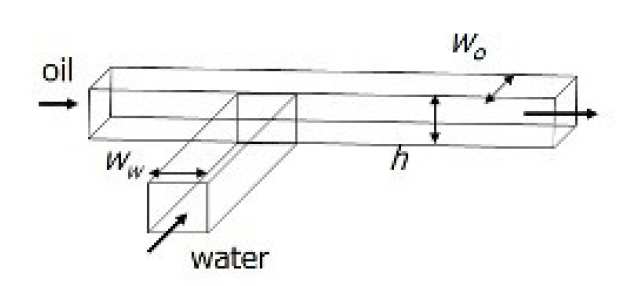

In a classical T-junction, two channels are connected at a right angle. The ‘continuous’ — or ‘carrier’ — fluid (oil) flows in the main channel, whereas the ‘discontinuous’ — or ‘dispersed’ — fluid (aqueous) flows in the secondary orthogonal channel. Three different forces play a role in the droplet break-up at the junction: the surface tension force, the shear stress force and the force resulting from the presence of the plug in the continuous flow, which increases the resistance to flow of the continuous fluid.