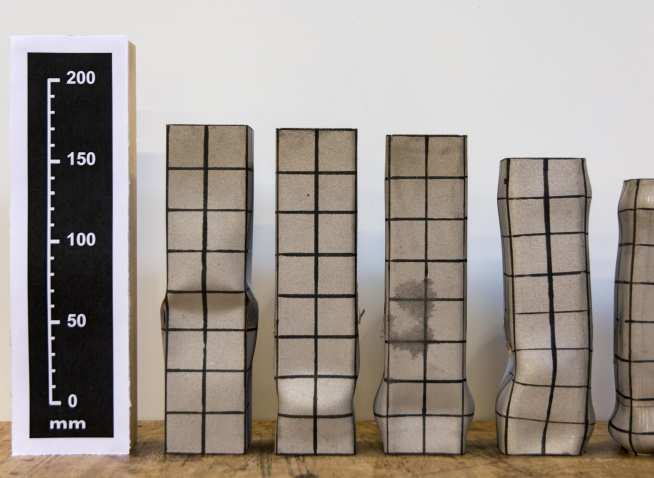

Additive manufacturing (AM), more widely known as 3D printing, is a production method in which material is built-up from successive layers to free-form geometries. Until now, metallic structural components that constitute buildings and bridges are typically prismatic in nature, with a substantial proportion of the material often not being fully utilised. AM, on the other hand, is capable of selectively placing material where it is structurally needed, which enhances design freedom and minimises material usage.

The advantages of AM are not limited to minimising material usage though; its unique ability to join layers of material can be used to form intricate geometries that may be too difficult, or even impossible, to achieve by conventional fabrication means. This is especially appropriate for the field of construction in which sustainability and new topology optimisation objectives are constantly driving the industry towards more structurally efficient designs.

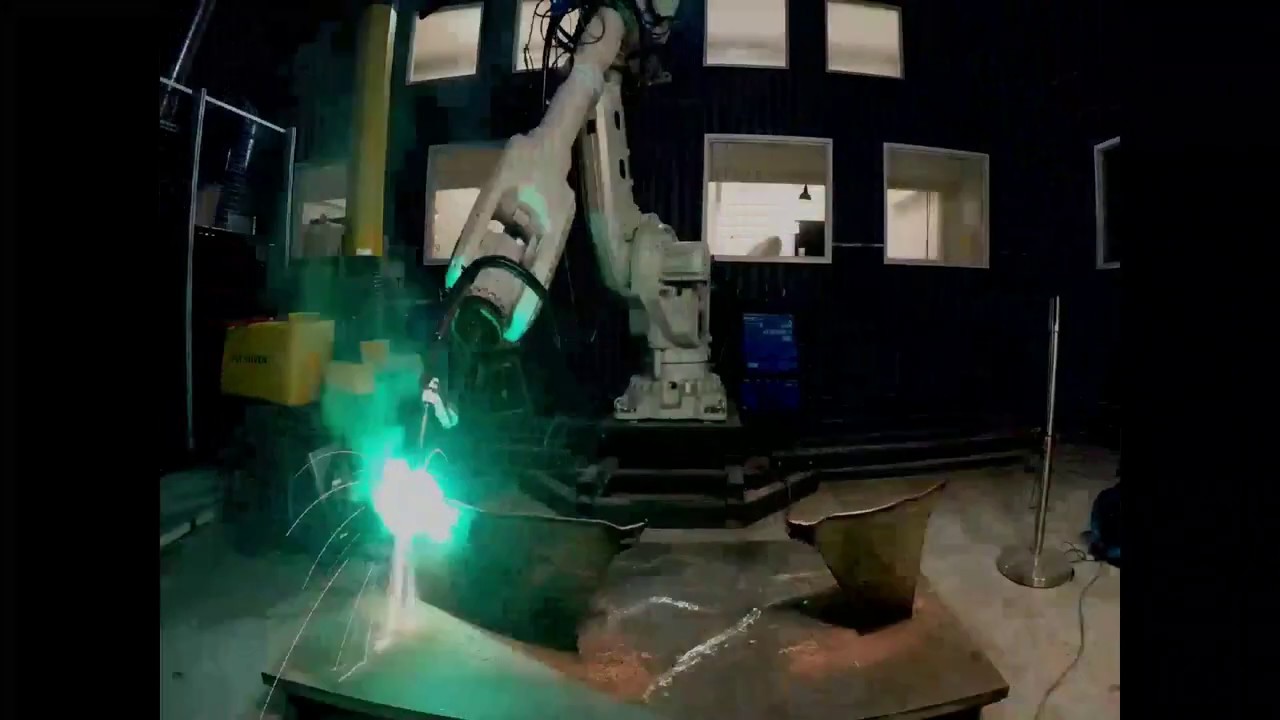

Researchers from the Steel Structures Research Group have tested material coupons and structural sections manufactured using two different 3D printing methods – Direct Energy Deposition (DED) and Powder Bed Fusion (PBF) [1]. In parallel with the laboratory testing, the group are currently working with MX3D on the world’s first 3D printed metallic bridge, which is projected for completion towards the end of 2018 in the centre of Amsterdam, Netherlands. A detailed finite element model, “The MX3D Digital Twin”, was also developed at Imperial College London and tests on the actual printed bridge were conducted in Amsterdam for the purposes of validating the numerical simulations.

News on the bridge and the underpinning research:

Prof Gardner presentation on MX3D bridge testing

Testing and simulation of the MX3D bridge

Researchers of the group are also involved in INTEGRADDE, a major European project, the goal of which is to develop a novel manufacturing methodology capable of ensuring the manufacturability, reliability and quality of a target metal component from the initial product design in strategic metalworking sectors.

INTEGRADDE combines research on building strategy optimisation, multi-scale and multi-physics modelling, hardware-independent building process, automatic building strategy generation, online self-adaptive control and inline quality assurance for the manufacturing of certified metal parts.

More details can be found in:

http://www.integraddeproject.eu/project

[1] Buchanan, Craig & Matilainen, Ville-Pekka & Salminen, Antti & Gardner, Leroy. (2017). Structural performance of additive manufactured metallic material and cross-sections. Journal of Constructional Steel Research. 136. 35-48. DOI: 10.1016/j.jcsr.2017.05.002.

Opportunities

Within the general area of steel structures, there are numerous ongoing research projects and opportunities for collaboration. Applications are welcome at any time of year.

Enquiries may be made to leroy.gardner@imperial.ac.uk