Building an electronic device on textiles using electronic fibres paves the way to wearable applications based on their flexibility and breathability.1

Building an electronic device on textiles using electronic fibres paves the way to wearable applications based on their flexibility and breathability.1

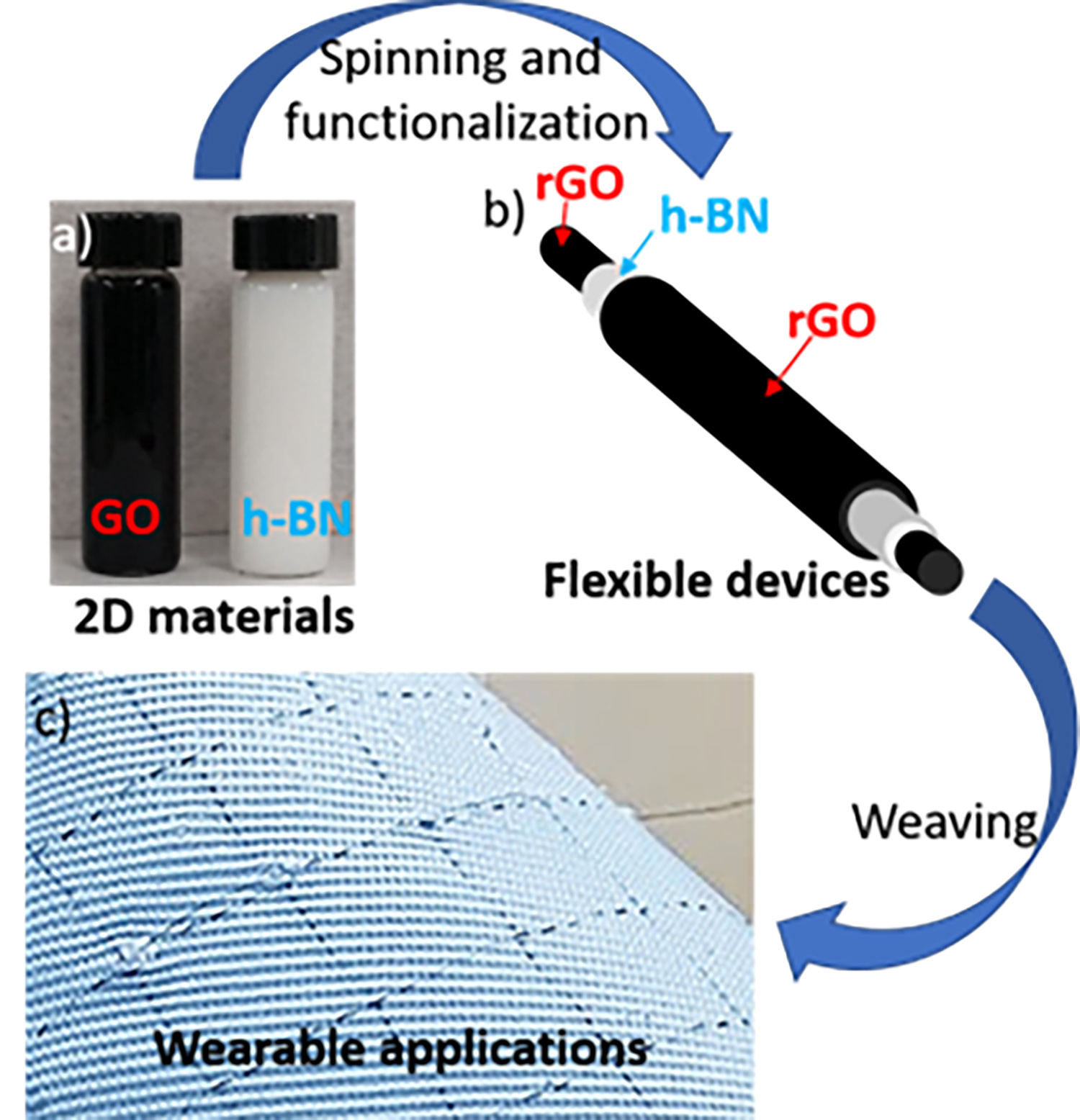

Two-dimensional (2D) materials, show reliable chemical stability, high mechanical strength, and attractive electrical and optical properties such as high conductivity or mobility, high optical transparency or light modulation efficiency.2

Together with their environmental stability some 2D materials are key elements to obtain wearable electronic devices enabling skin-contact biosensors, light emitting, and energy storage fabrics.2,3

Our group develops electronic fibres made of 2D materials (e.g., graphene oxide/reduced graphene oxide, hexagonal boron nitride, MoS₂) or biocompatible polymers using wet spinning processes or extrusion followed by fibre functionalisation to produce flexible electronic devices through various coating techniques.

We pioneer the designing and development of flexible capacitors, transistors and photodetectors, creating conducting and sending fibres with electrical and mechanical performance, high sensitivity and beyond state-of-the-art biocompatibility.

1 F. Torrisi and T. Carey, Nano Today, 2018, 23, 73–96.

2 S. Seyedin et al. Nanoscale, 2021, 10.1039/D1NR02061G

3 A. Lung et al. MRS Bulletin, 2021, 46,

Contact

Dr Felice Torrisi

Senior Lecturer in Chemistry of Two-Dimensional Materials

401A

Molecular Sciences Research Hub

White City Campus

f.torrisi@imperial.ac.uk

+44 (0)20 7594 5818