Many of the fundamental tools developed in the three competence areas of Product & Process Design, Operations & Control and Modelling & Model Solution Tools are motivated by the challenges arising in this application domain. Through this domain, we serve several process industries such as bulk chemicals (including petrochemicals and oil & gas), pharmaceuticals & agrochemicals, specialty chemicals and biofuels.

The work of the Chemical Manufacturing Systems Engineering application area has several strands:

Multiscale Modelling of Biorefineries

There is a large body of literature regarding the choice and optimization of different processes for converting feedstock to biofuels and bio-commodities; moreover, there has been some reasonable technological development in bioconversion methods over the past decade. However, the eventual cost and other important metrics relating to sustainability of biofuels production will be determined not only by the performance of the conversion process, but also by the performance of the entire supply chain from feedstock production to consumption.

Moreover, in order to ensure world-class biorefinery performance, both the network and the individual components must be designed appropriately, and allocation of resources over the resulting infrastructure must effectively be performed. The goal of this project is to develop a framework and methodology for multi-scale modelling of flexible biorefineries, and the integration of process models with supply chain models to answer holistic supply chain questions, such as what are the prospects for second generation bioenergy crops, where are the main cost

and efficiency bottlenecks, etc.

Synthesis of Chromatographic Strategies of Antibody Purification Processes

The strategies employed in chromatography steps play a key role in downstream processes for monoclonal antibody (mAb) manufacture. A key decision for mAb purification is the selection of the chromatography sequence. There usually exist multiple chromatography steps in the mAb purification process, and each step has a number of suitable candidate resins/types for selection.

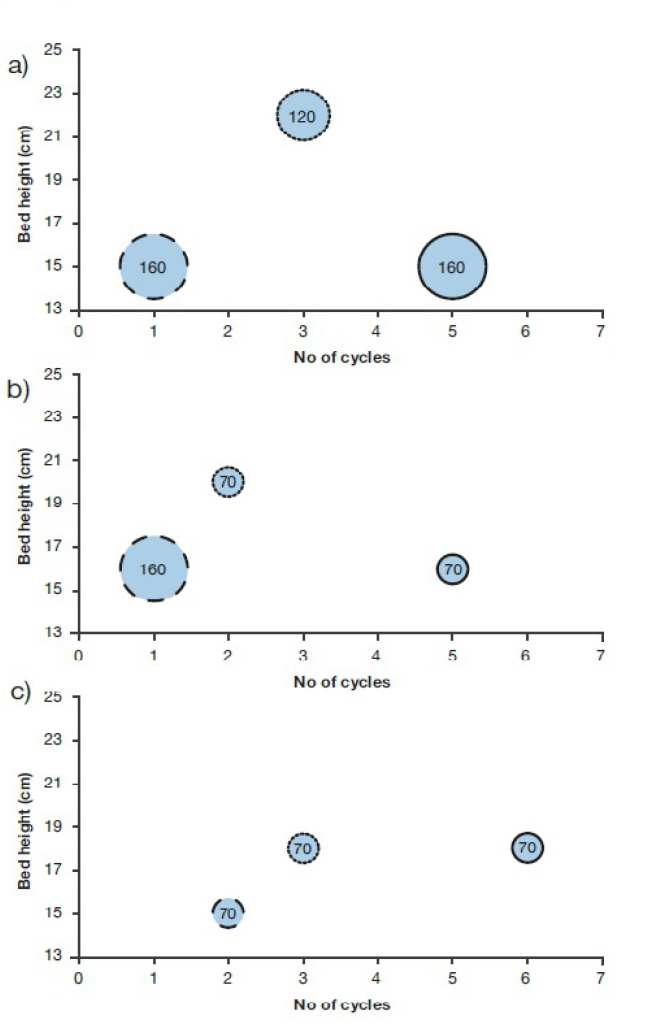

The candidate resins often have different characteristics, e.g., yield, price, dynamic binding capacities. Here an importation issue is how to choose the best combination of resins/types for all chromatography steps to be of most benefit to the whole downstream process. Also, at each chromatography step, another key decision is the column sizing strategy, e.g. opting to run a smaller column for several cycles so as to reduce resin costs or a large column for fewer cycles so as to save time and labour costs. Decisions on the chromatography column sizes include the selection, the bed height and diameter of each column and the number of cycles to run and the number of columns to use in parallel.In this project, an integrated optimisation-based framework is proposed for chromatography step sequencing and column sizing in mAb purification processes.

Chromatography sequencing decisions include the resin selection at each typical step, while the column sizing decisions include the number of columns, the column diameter and bed height, and number of cycles per batch (see figure 2). A mixed integer nonlinear programming (MINLP) model was developed and then reformulated as a mixed integer linear fractional programming (MILFP) model. A literature approach, the Dinkelbach algorithm, was adopted as the solution method for the MILFP model.

Sustainable Manufacturing of Transparent Conducting Oxide (TCO) Inks and Thin Films

This project seeks to develop processes and resources towards sustainable and inexpensive high quality transparent conducting oxide (TCO) films (and printed tracks) on float glass, plastics and steel. In particular replacement materials for Indium Tin Oxide (ITO) and F-doped Tin Oxide (FTO). In this project we will develop sustainable upscaled routes to TCO materials from precursors containing earth abundant elements (titanium, aluminium, zinc) with equivalent or better figures of merit to existing TCOs. One the objectives of the project is to apply Life-cycle modelling and cost benefit analyses by taking a holistic approach to the considerations of energy, materials consumption and waste and, in consultation with key stakeholders and policy makers, identify best approaches to making improvement or changes, e.g. accounting for environmental legislation in nanomaterials, waste disposal or recyclability of photovoltaics.

Optimal Synthesis of Water Networks with Membrane Regenerators

Due to the high demand of water consumption together with the drive for achieving sustainable development, water network synthesis problems have received increasing attention in the PSE community. In the objective of minimizing freshwater use and wastewater generation, water can be reused by channelling the effluent from a water-using operation to other operations, and possibly recycled to the operations where it was generated. In further reducing freshwater and wastewater flowrates after exhausting recovery opportunities via direct reuse/recycle, water regeneration can be considered, which involves performing partial treatment on the effluent by using water treatment and purification units such as membranes and steam stripping prior to reuse/recycle.

The main objective in this project is to synthesize an optimal water network given the three elements of water sources with fixed flowrates and contaminant concentrations; water sinks with fixed flowrates and maximum allowable inlet concentration limits; and water regenerators. To this end, we have developed a source–regenerator–sink superstructure that allows all feasible interconnections of the elements to embed numerous alternative configurations for direct reuse/recycle, regeneration–reuse, and regeneration–recycle. The superstructure and regenerator models lead to a mixed-integer nonlinear program (MINLP) that optimizes the interconnections as described by total stream flows and concentrations. We successfully applied the MINLP model on a refinery case study that involves 28 sources including freshwater; 2 regenerators: mud trap-corrugated plate interceptor and a singlestage reverse osmosis network; and 14 sinks including two terminal sinks (effluent treatment plant and discharge to the environment). A globally optimal water network topology was attained with promising results of more than 50% annual savings in freshwater use.

Surrogate based Optimisation for Design of Pressure Swing Adsorption Systems

Pressure swing adsorption (PSA) is a cyclic adsorption process for gas separation and purification. PSA units have been installed in the process industry for applications such as air separation, hydrogen purification, and gas drying. Because of its low energy requirement it is considered to be a cheaper alternative to traditional absorption techniques.

In this study, a non-intrusive surrogate based optimisation procedure based on Kriging is suggested for design of PSA systems. The Kriging models are employed to guide the search more efficiently. To illustrate the significant improvement that could be achieved, we have compared surrogate based optimisation based on a genetic algorithm (GA) and multi-start sequential quadratic programming (SQP), and efficient global optimisation (EGO). The case study considered is the design of a dual piston PSA system. The general surrogate based optimization procedure

with Kriging has been shown to suffice with GA and multi-start SQP, while it also allows the use of other optimization methods.

.png)