3d print and test

The development of a mesoscale structural model, rather than a continuum model, allows for additive manufacturing of the resulting structure. With suitable manipulation of the bone adaptation algorithm, 3D printing in materials including a wide range of polymers and metals, permits the manufacture of frangible bone simulants for use in experimental testing, as well as the potential design and manufacture of bioresorbable scaffolds and orthopaedic implants, sympathetic to the remaining skeletal structural architecture.

A preliminary study was funded by the Defense Science Technology Laboratory (DSTL), in cooperation with Imperial College London, which constitutes a Phase 1 manufacture of a human lower limb frangible surrogate for use in ballistic, impact and blast testing, indicating realistic injury patterns. It was designed as a proof of concept for the production of such surrogates using additive manufacturing based on computationally derived bone structures.

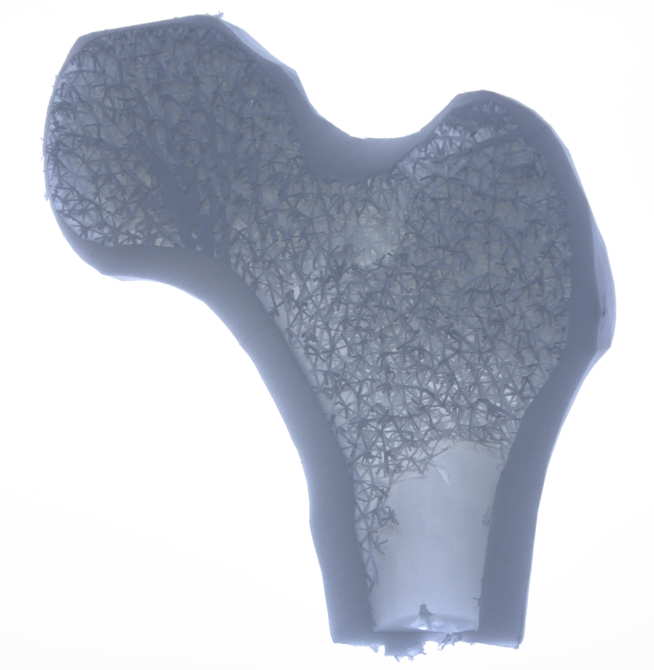

As a result, frangible surrogates representing individual pelvis, femurs, tibia/fibula systems with membrane and ligaments were designed based on the mesoscale models. A picture of a half proximal femur print is given in Figure 1. Figure 2 shows the print of the right pelvis trabeacular bone. Nylon material tests were conducted prior to the surrogate manufacture to inform the surrogate design. A full lower limb surrogate including knee, knee ligaments, and a representation of soft tissue in the thigh and the shank was also designed and manufactured (Figure 3).

Researchers

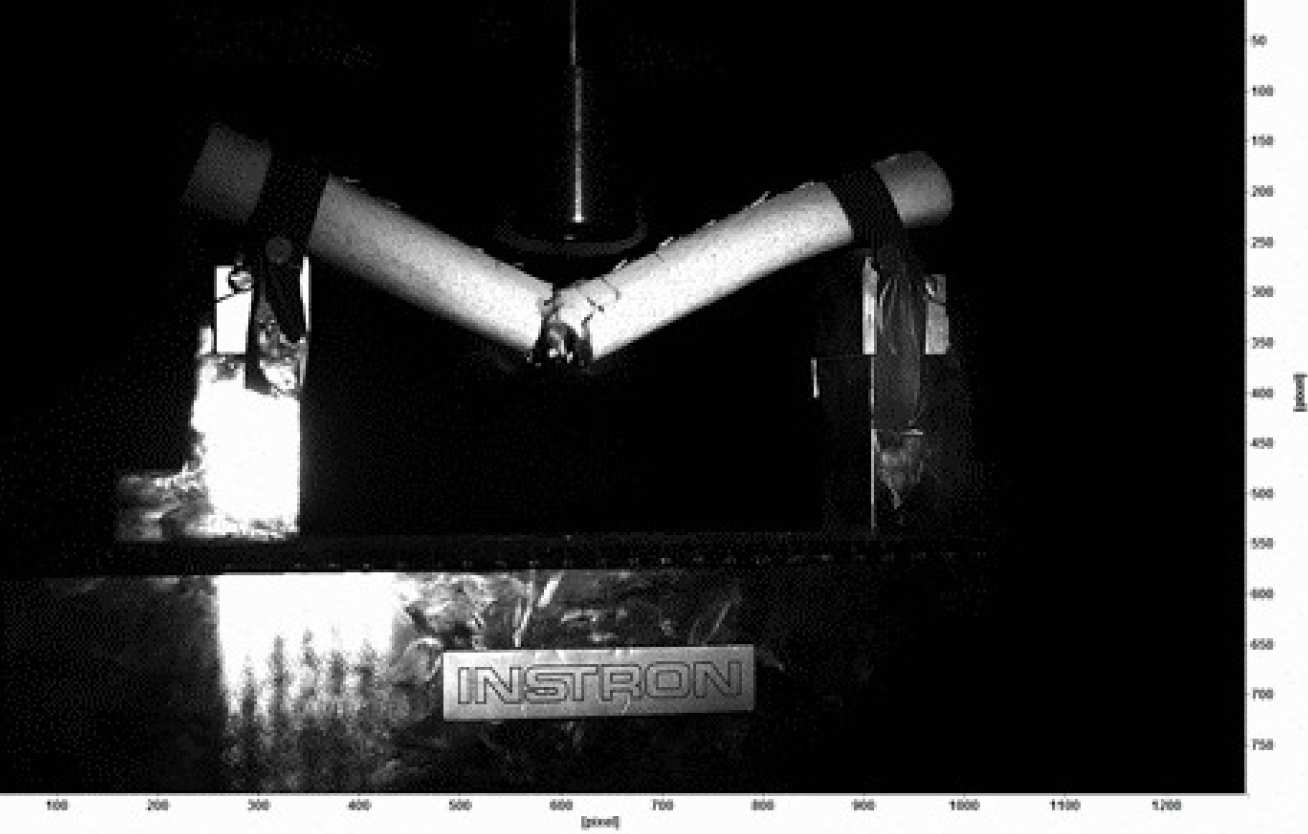

The individual bones were mechanically tested in compression and bending at different loading rates including impact. They presented mechanical behaviour qualitatively similar to real bone, such as the butterfly fracture pattern in bending tests shown in Figure 1.

The full lower leg was tested in a scenario of solid blast in seated configuration (Anti-vehicle Underbelly Blast Injury Simulator) and exhibited an expected failure at the ankle. Further development of these surrogates will focus on designing materials able to accurately represent bone and ligaments behaviour in a quantitative manner, while being compatible with the manufacturing pipeline used.

Researchers

Dr Claire Villette

Dan Zaharie

Dr Andrew Phillips

AnUBIS 3D-printed Frangible Surrogate test

Anubis test

Contact us

Dr Andrew Phillips

Imperial College London

Structural Biomechanics

Skempton Building

South Kensington Campus

London SW7 2AZ, UK

Creative Commons license

This work by Imperial College London, Structural Biomechanics is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.