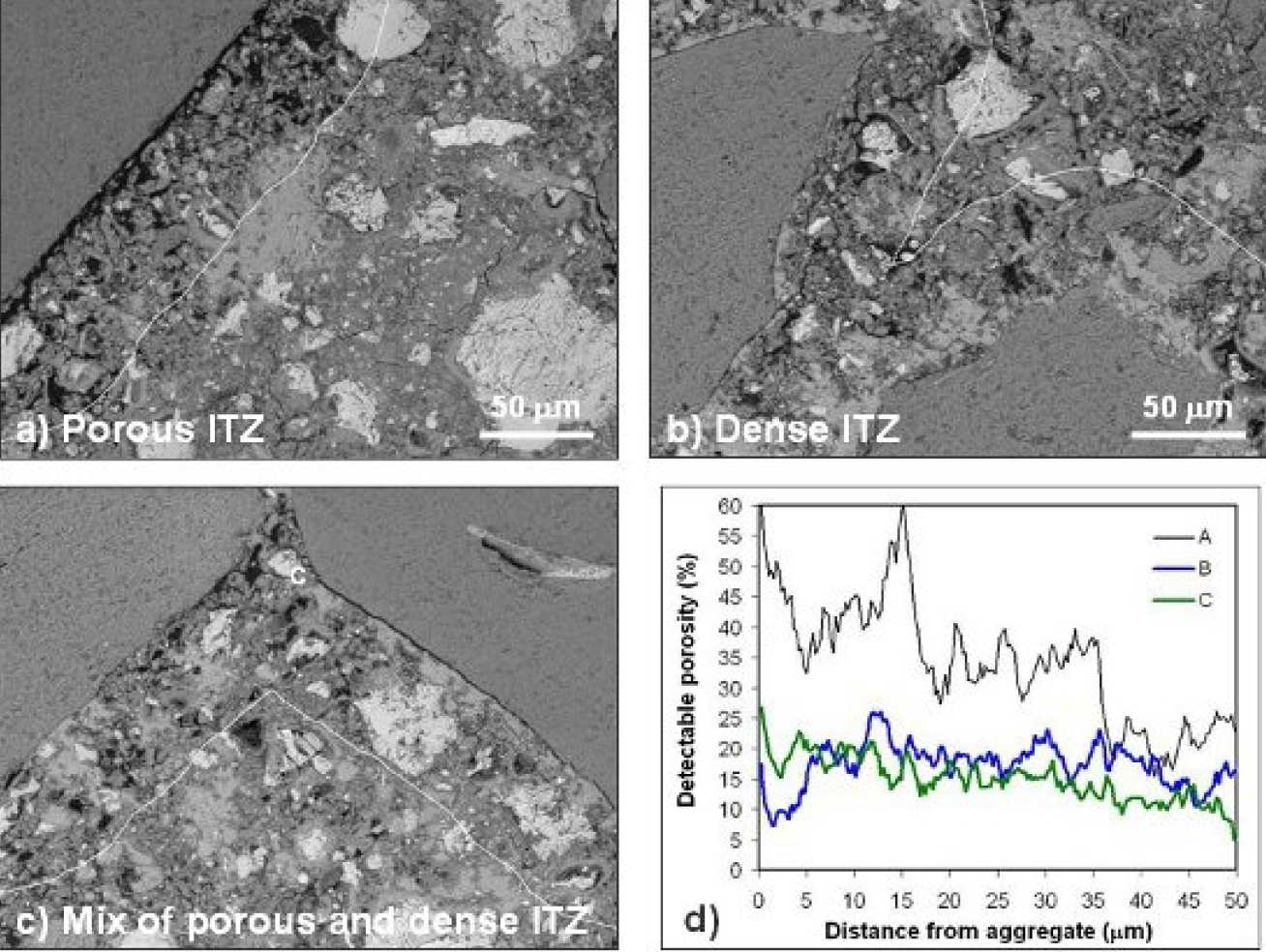

The ‘interfacial transition zone’ (ITZ) refers to the paste region surrounding each aggregate particle in concrete. The ITZ is structurally inferior because it contains higher porosity (Fig. 1) and lower cement content than the ‘bulk’ paste region farther away. Microcracks often initiate and propagate preferentially in the ITZ. It is generally thought that penetration of deleterious species occurs mainly through the ITZ and this forms the basis of many transport models for concrete.

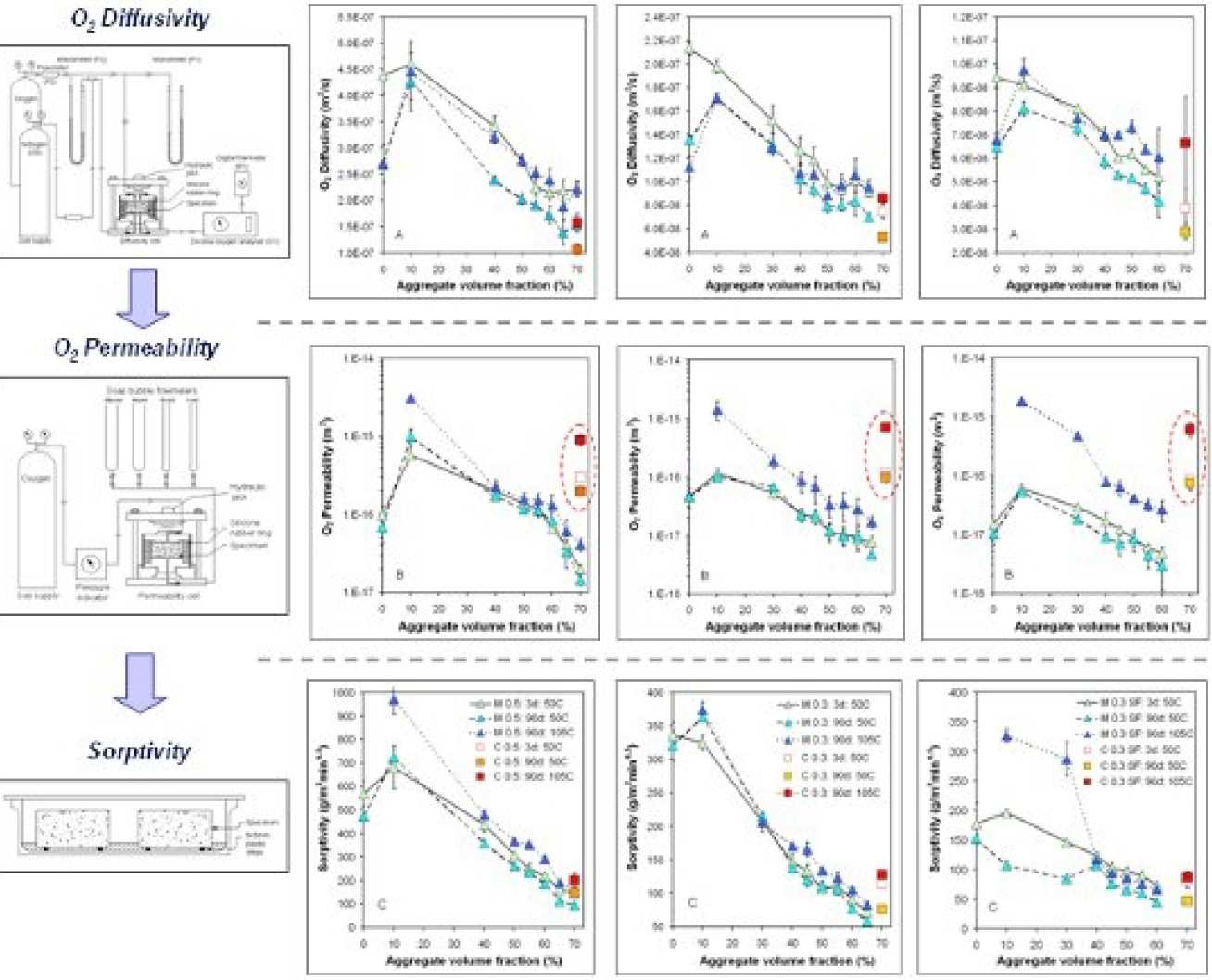

In this study1, we presented a critical review of the ITZ that highlights inconsistencies in previous studies, and carried out an extensive experimental study to determine the relative importance of ITZ and microcracking on three transport mechanisms. Over 200 samples of pastes, mortars and concretes were tested. Variables include w/c ratio, cement type, aggregate content, curing age and conditioning temperature.

The study concluded that the net effect of the ITZ on macro transport properties is small, even though the ITZs are overlapping and may have higher porosity and higher local transport properties than the bulk paste. Total porosity and the presence of microcracks far outweigh any effects of the ITZ on transport properties, particularly for pressure-induced flow. Thus, mass transport is governed by the entire pore structure within the cement paste and not just within the ITZ.

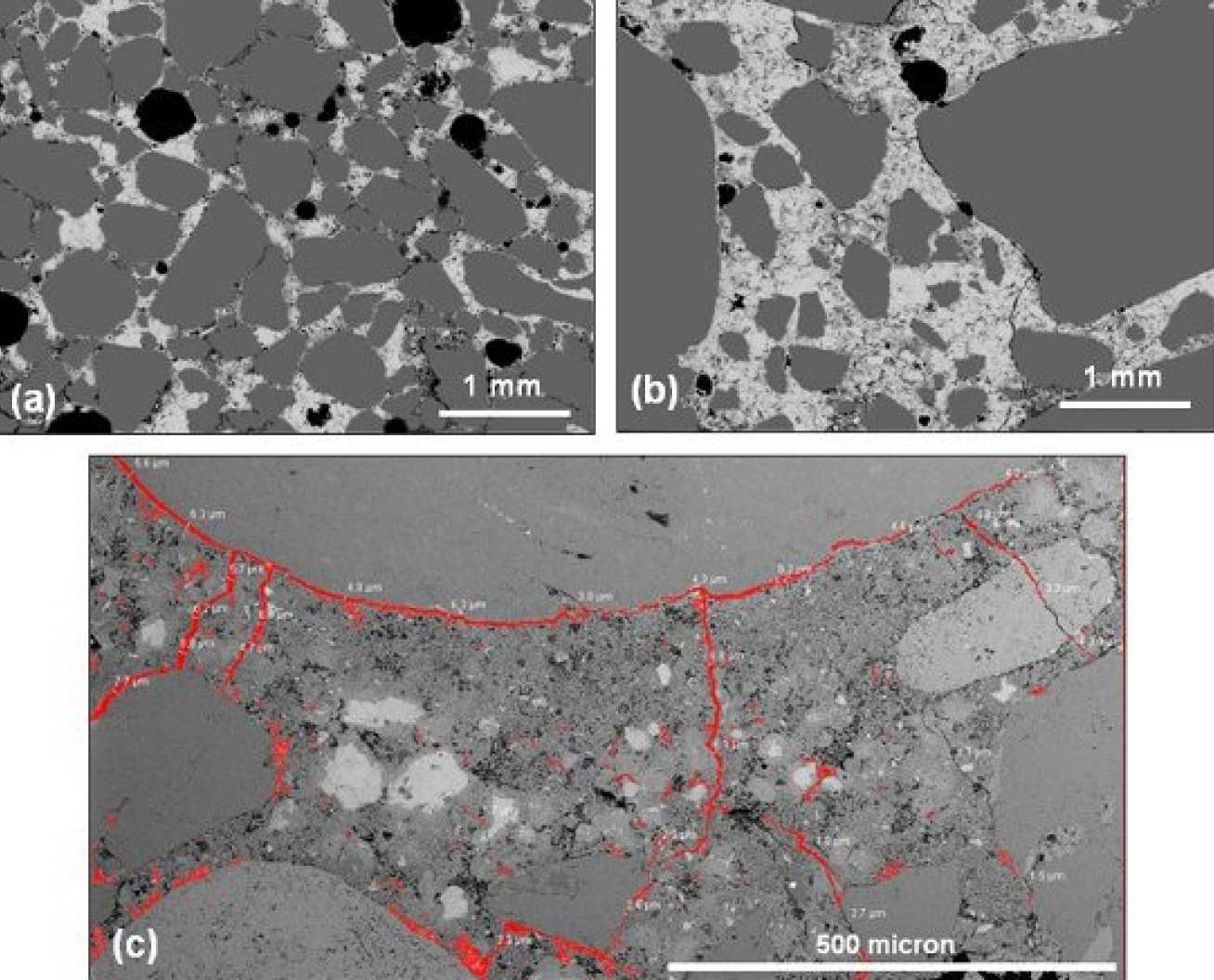

Transport resistance of mortars increased with increasing ITZ fraction for all cases. No critical threshold sand content linked to an ITZ percolation effect was found, even in samples that were deliberately damaged by drying at 105oC. Severe oven-drying induces microcracks with widths of 0.5-10mm that are interconnected and randomly orientated as shown in Fig. 3.

The microcracks have a significant influence on permeability, which increased by up to a factor of 30, when comparing the same sample dried at 50°C and 105°C. Diffusivity and sorptivity increased by only a factor of 2. Despite a lower ITZ fraction, concretes have about the same diffusivity and sorptivity, but significantly higher permeability than mortars with the same aggregate fraction. Results from image analysis (Fig. 3) suggest that the higher permeability of concrete is attributable to more microcracking.

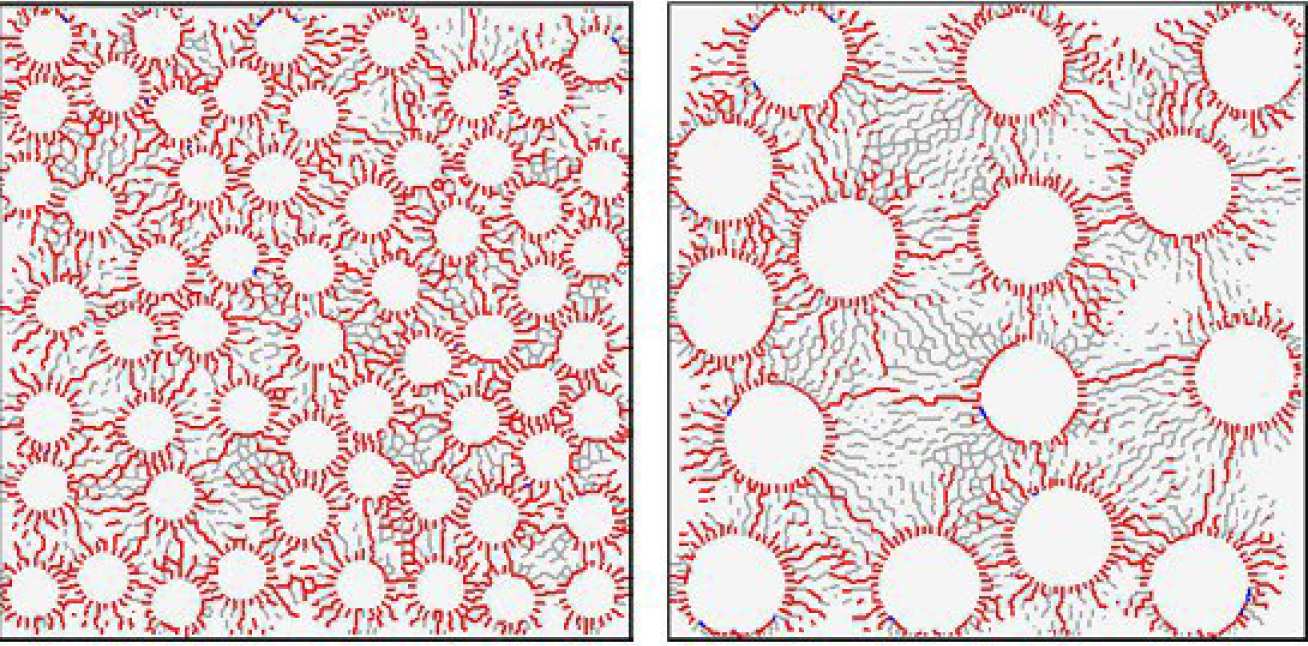

The experimental results are supported by numerical modelling, for example by applying a three-phase composite sphere model to examine the influence of ITZ on steady-state chloride diffusivity2. Results from lattice-based finite element modelling of shrinkage-induced microcracking (Fig. 4) also showed that the higher permeability in concrete is due to wider cracks that form, as a result of the larger aggregate size in concrete.

References:

- H.S. Wong, M. Zobel, N.R. Buenfeld, R.W. Zimmerman (2009), Influence of the interfacial transition zone and microcracking on the diffusivity, permeability and sorptivity of cement-based materials after drying, Mag. Concr. Res., 61, 571-589.

- J.J. Zheng, H.S. Wong, N.R. Buenfeld (2009), Assessing the influence of ITZ on the steady-state chloride diffusivity of concrete using a numerical model, Cem. Concr. Res., 39, 805-813.

- P. Grassl, H.S. Wong, N.R. Buenfeld (2010), Influence of aggregate size and volume fraction on shrinkage induced micro-cracking of concrete and mortar, Cem. Concr. Res., 40, 85-93.

- H.S. Wong, A.M. Pappas, R.W. Zimmerman, N.R. Buenfeld (2011), Effect of entrained air voids on the microstructure and mass transport properties of concrete, Cem. Concr. Res., 41, 1067-1077

- Z. Wu, H.S. Wong, N.R. Buenfeld (2015), Influence of drying-induced microcracking and related size effects on the mass transport properties of concrete, Cem. Concr. Res., 68, 35-48

- M.K. Head, H.S. Wong, N.R. Buenfeld (2008), Characterising aggregate surface geometry in thin sections of mortar and concrete, Cem. Concr. Res., 38, 1227-1231

- H.S. Wong, N.R. Buenfeld (2006), Euclidean Distance Mapping for computing microstructural gradients at interfaces in composite materials, Cem. Concr. Res., 36 [6] 1091-1097

- S. Dehghanpoor Abyaneh, H.S. Wong, N.R. Buenfeld (2013), Modelling the diffusivity of mortar and concrete using a three-dimensional mesostructure with several aggregate shapes, Computational Materials Science, 78, 63-73.

Contact us

Prof Nick Buenfeld

Tel: +44 (0)20 7594 5955

E-Mail: n.buenfeld@imperial.ac.uk