Cracking of concrete structures is a common problem due to the intrinsic brittleness of the material. This may lead to severe loss of durability and water tightness. Conventional methods for mitigating this problem such as providing additional reinforcement or movement joints in new structures and resin injection to seal cracks in existing structures may not always be appropriate or sufficient.

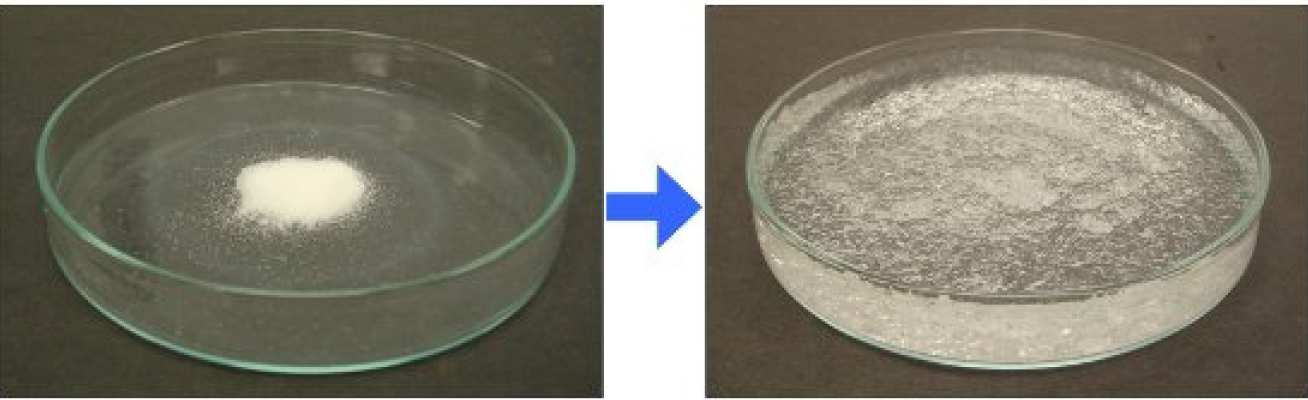

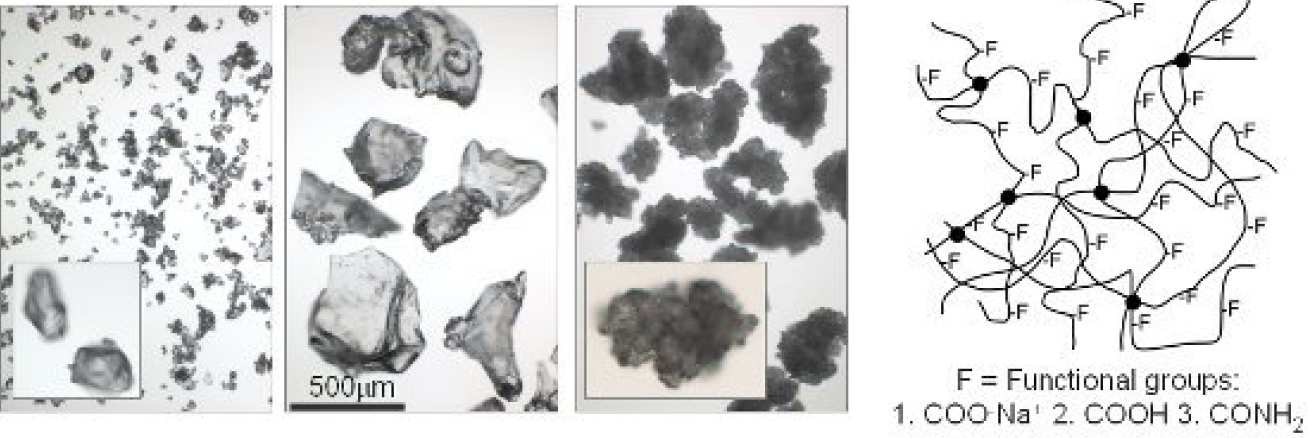

The aim of this study is to investigate the potential of superabsorbent polymers (SAP) as an admixture for self-sealing cracks in concrete. SAP are unique cross-linked polymers that can absorb a vast amount of liquid and swell substantially to form a soft insoluble gel (Fig. 1 & 2). Common types of SAP are poly(acrylate) and poly(acrylate-co-acrylamide) that are widely used in personal care products such as nappies.

Other applications of SAP include biomedical bandages, agricultural soil conditioning, waste solidification and meat packaging1. The swelling of SAP is highly dependent on pH, ionic content and concentration of the solution2,3. For example, SAP swells significantly in deionised water (~200g/g), but only slightly when added to concrete (~5-20g/g). This unique feature allows SAP to be exploited for self-sealing cracks.

Self-Stealing mechanisim

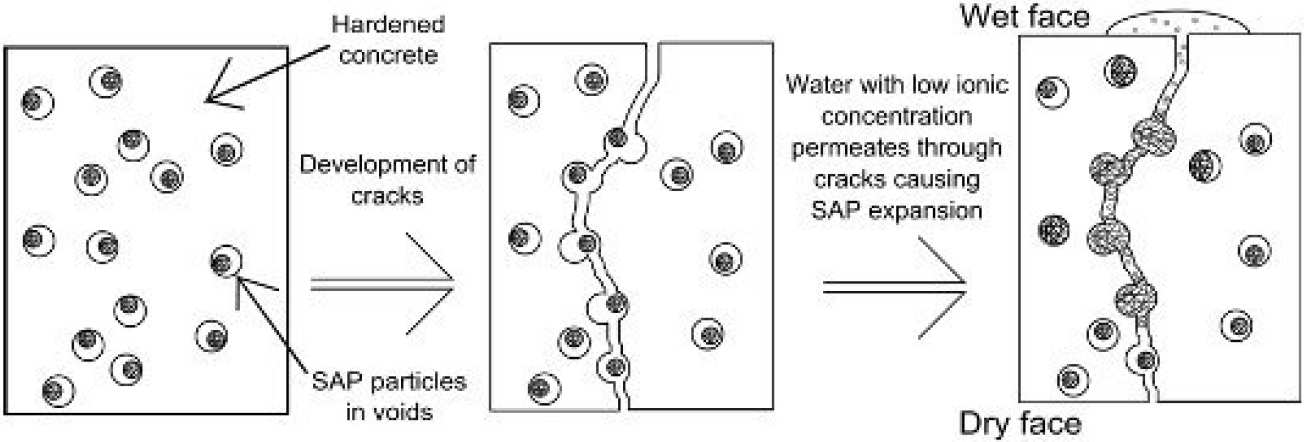

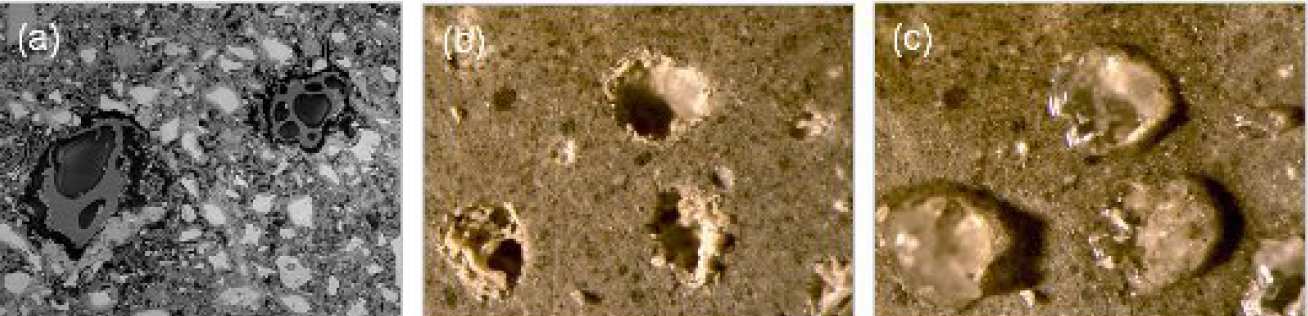

As concrete hardens, the SAP releases water and shrinks (Fig. 3), leaving behind pores with sizes ranging from tens to hundreds of microns. The SAP then lie dormant in the microstructure until cracking occurs. When the concrete is subjected to external wetting, ingress of moisture via cracks causes the SAP to swell again. Fluids with ionic concentration lower than the concrete pore solution, e.g. shallow ground water, triggers the SAP to swell beyond the pore and into the crack (Fig. 4). This subsequently blocks the crack and reduces flow.

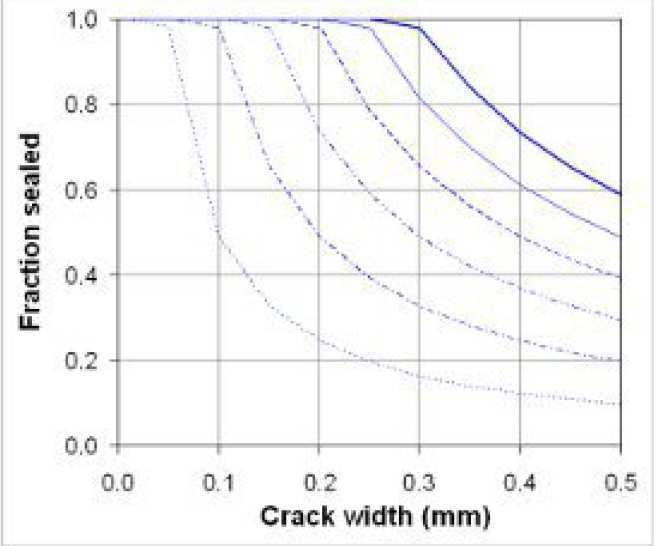

The fraction of crack sealed depends on crack width, dosage and swelling ratio of the SAP. Assuming that the swelling ratio of SAP in the cement paste and crack are 10g/g and 80g/g respectively, our modelling shows that the dosage of SAP required to completely block a 300μm crack is about 0.6% wt. cement (Fig. 5).

Effect of SAP on transport properties

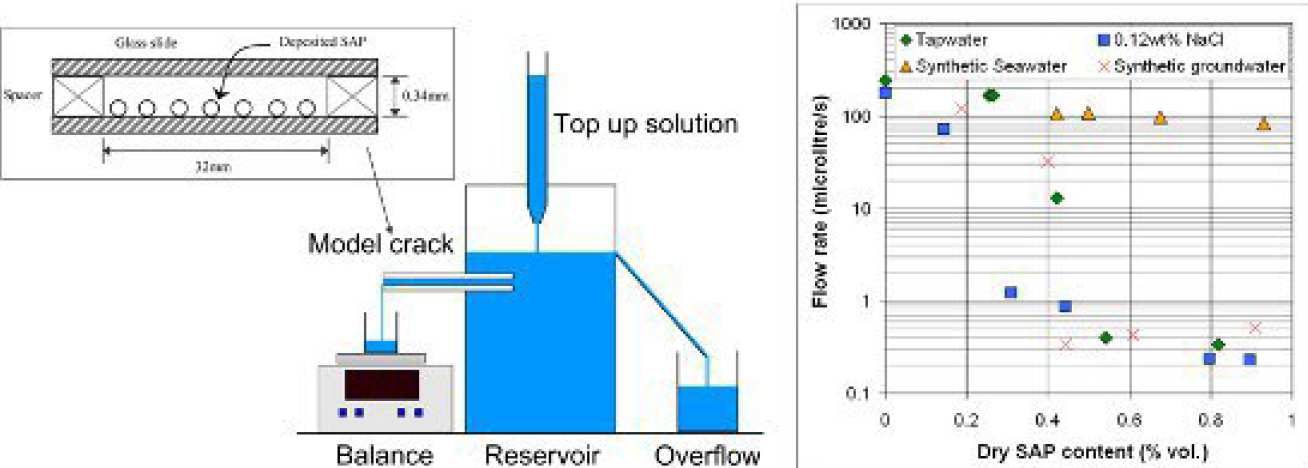

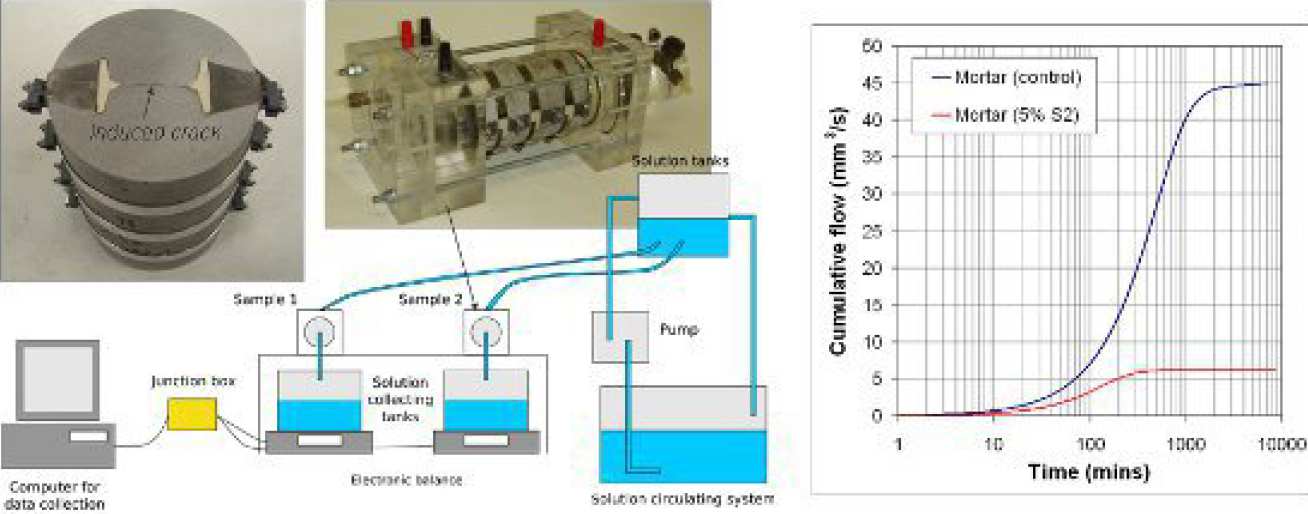

Measurements of flow through model cracks, pastes and mortar specimens containing different types and amounts of SAP have been carried out4,5. Results show that the flow rate through a 330μm model crack drops significantly when the SAP content is greater than 0.4% vol. (Fig. 6). The flow rate and cumulative flow of dilute NaCl solution through cracked cement paste and mortar specimens containing SAP were significantly lower than the control (Fig. 7).

Conclusions

The potential of SAP as an admixture to develop self-sealing concrete has been demonstrated with experimental and modelling work. Further work to gain a better understanding of the effect of SAP on the mechanical properties and durability of cracked concrete is on going.

References:

- F. Buchholz & A. Graham (1998), Modern superabsorbent polymer technology, John Wiley, New York.

- T. Tanaka et al. (1980), Phase transitions in ionic gels, Phys. Rev. Lett., 45, 1636-1639

- J. Ricka & T. Tanaka (1984), Swelling of ionic gels: quantitative performance of the Donnan theory, Macromolecules, 17, 2916-2921

- H.X.D. Lee, H.S. Wong & N.R. Buenfeld (2010), Potential of superabsorbent polymer for self-sealing cracks in concrete, Advances in Applied Ceramics., 109, 296-302

- H.X.D. Lee, H.S. Wong & N.R. Buenfeld (2010), Self-sealing cement-based materials using superabsorbent polymers, RILEM Conference on the Use of Superabsorbent Polymers and Other New Additives in Concrete, 15-18 Aug, TU Denmark.

- H.X.D. Lee, H.S. Wong, N.R. Buenfeld (2010), Estimating the swelling ratio of superabsorbent polymers in cement-based materials, RILEM International Conference, Use of superabsorbent polymers and other new additives in concrete, Lyngby, 15-18 Aug, 163-170

- H.X.D. Lee, H.S. Wong, N.R. Buenfeld (2008), The potential of superabsorbent polymer for self-sealing cracks in concrete, 28th Cement and Concrete Science Conference, University of Manchester, 15-16th Sept, IOM3

- H.X.D. Lee, H.S. Wong, N.R. Buenfeld (2015), Self-sealing cracks in concrete using superabsorbent polymers, Cement and Concrete Research, In press

Contact us

Prof Nick Buenfeld

Tel: +44 (0)20 7594 5955

E-Mail: n.buenfeld@imperial.ac.uk