This group is led by Prof Christopher Gourlay.

Gourlay widget

- Microstructure evolution in electronic solders

- Third generation Pb-free solders for high reliability electronics

- Investigation of the influence of melt undercooling on the evolution microstructure of electronic solders

- Formation of Al-Mn-based intermetallic compounds in Mg-Al-Mn-based alloys

- Controlling intermetallic morphology by harnessing twinning during crystal growth

- Carbon inoculation of AZ91 Mg alloy and effects of grain morphology on the microstructure of Mg17Al12

- Undercooling – microstructure - performance relationships in Sn-based solders

- Intermetallic coarsening in Sn-3Ag-0.5Cu solder joints

- The effect of impurity Cu on recycled Mg alloys and solutions

Dr Jingwei Xian (Research Associate)

Dr Jingwei Xian (Research Associate)

Ag3Sn crystals are important in the performance of Ag-containing Pb-free solders. The size, shape and volume fraction of Ag3Sn crystals in forms of primary and eutectic influence the reliability of joints. This project focuses on characterising the crystal growth of primary Ag3Sn crystals during solidification and quantifying the coarsening mechanisms of eutectic Ag3Sn particles during isothermal ageing and thermomechanical cycling. The interplay between Ag3Sn crystals and beta-Sn dendrite arms during solidification is also studied by controlling the nucleation undercooling of beta-Sn. The project uses analytical electron microscopy combined with real-time synchrotron radiography to reveal Ag3Sn crystal growth characteristics and develops automated image analysis algorithms to quantify the Ag3Sn particle ripening and coalescing kinetics.

Chen-Lin Hsieh (Research Postgraduate)

Chen-Lin Hsieh (Research Postgraduate)

Solder joints are prone to fatigue and subsequent failure under high operation temperatures and wide temperature variations. Thermal fatigue is a particular challenge for the applications of electronic systems in automobiles and aircrafts. A series of solder alloys are being developed in order to address this issue. These alloys are essentially Sn-Ag-Cu (SAC) alloys with combined additions of Bi, Sb, and In up to 7%, termed third-generation Pb-free solder alloys. These alloys have been shown to display better fatigue lifetime than SAC alloys, mainly attributed to solid solution strengthening by dissolved atoms and dispersion strengthening by precipitates. Alloys with both Bi and Sb additions appear to further outperform other third-generation alloys, but the reason behind this is still unclear.

This project aims to investigate how combined Bi and Sb additions influence the microstructures of solder alloys, and how the consequent microstructures contribute to the optimum thermal fatigue performance. Scanning electron microscopy, electron backscattered diffraction techniques and thermal cycling tests will be applied to analysis the microstructures of solder joints before and after thermal cycling. By doing so, the roles of precipitates like SbSn and Bi in the damage evolution will be investigated in more detail. The knowledge developed from this work would be useful for manufacturers to design solder alloys with superior reliability under harsh environments.

Xiaomei Shen (Research Postgraduate)

Xiaomei Shen (Research Postgraduate)

In Sn-based solders, nucleation usually occurs at relatively larger undercooling. However, the lack of the relationship between the degree of undercooling and the evolution microstructure of electronics hinders the improvement of the performance in solder joints under harsh environment. Based on the study of Sn-Pb and Sn-Bi binary alloys, this project is exploring the influence of the cooling rate and melt undercooling on the competition between different microstructures, analysing the quantifying the undercooling-microstructure relationships by building a model, and optimising the microstructure of solders for improving electronic reliability through novel characterisation and quantifications techniques. This project uses differential scanning calorimetry providing different cooling rates on samples. Through the analysis of the data from optical microscopy and scanning electron microscopy, the sequence of microstructure in Sn-Bi and Sn-Pb binary alloys could be revealed. Combined with the establishment of mathematical models, the evolution of microstructure quantitatively could be shown at different degrees of undercooling.

Di Wang (Research Postgraduate)

Di Wang (Research Postgraduate)

In collaboration with the Future Liquid Metal Engineering (LIME) Hub

Mg-Al-Mn-based alloys are the most widely used Mg alloys. Mn is added into the system for better corrosion performance, but it also forms varies Al-Mn-based intermetallic compounds in the Mg matrix during solidification. this project aims to study the formation of these compounds in Mg-Al-based alloys - how they nucleate, grow and evolve during melt handling, solidification and heat treatments.

Thanasis Zois (Research Postgraduate)

Thanasis Zois (Research Postgraduate)

Co-supervised by Dr Katharina Marquardt

Many engineering alloys contain intermetallic compounds (IMCs) as secondary phases which can either be beneficial strengthening phases or deleterious embrittling phases depending on their size, shape, and location/orientation in the microstructure. Among the most deleterious are IMCs that nucleate in the liquid as the first phase to form during solidification where they often grow to hundreds of micrometres in size. These are usually named “primary solidification phases”. In order to develop alloys with improved properties, there is a need to control the shape and size of these large primary IMCs. It has been suggested that this could be achieved by controlling twinned crystal growth or by promoting heterogeneous nucleation of IMCs, however, in order to investigate the perspective of these methods, it is first necessary to improve our understanding concerning how primary IMCs nucleate and grow in alloy melts. The project will mainly focus on IMCs that nucleate and grow in electronic solders and light alloy castings and key research areas will be how the crystal structure affects the growth mechanisms of the IMCs and how the melt undercooling affects the development of crystal defects. Furthermore, if this knowledge can be obtained, it would be interesting to explore if it can used to control the shape and size of harmful primary IMCs.

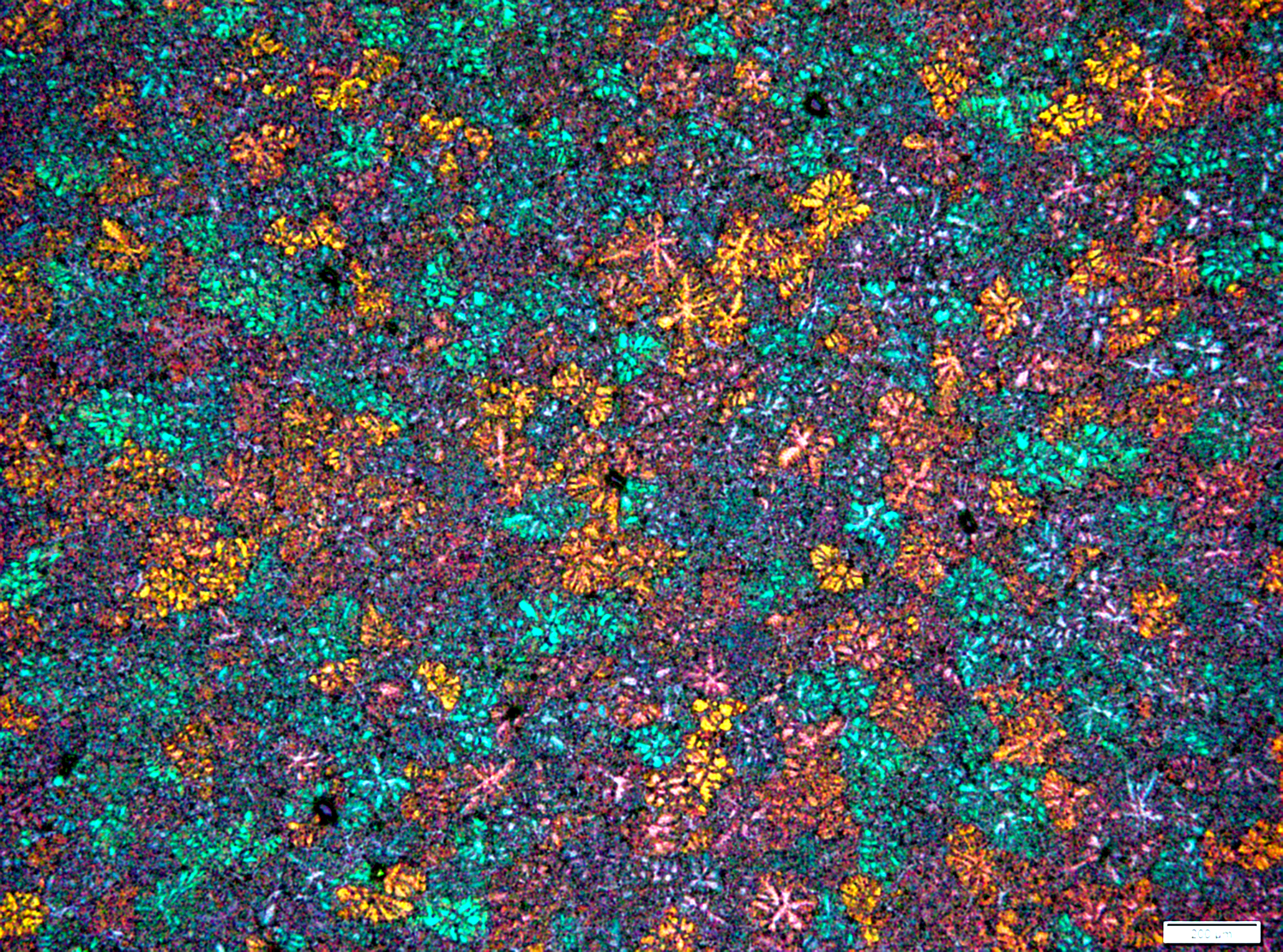

Cheng-Jung Lin (Research Postgraduate)

Cheng-Jung Lin (Research Postgraduate)

In collaboration with Dr Qianqian Li

Grain refinement is vital for enhancing magnesium alloys in terms of castability, formability, strength and ductility. The four main known methods of grain refining Mg-Al based alloys are superheating, the Elfinal process, native grain refinement and carbon inoculation, but these refining processes have not found widespread industrial use. Part of the reason for this is that the mechanisms of grain refinement in these methods is not fully understood. For instance, in the carbon inoculation method, the active Nucleant has been reported as Al4C3, Al2Mg2C2 and Al2CO, but this has not been confirmed. In this study, analytical electron microscopy approaches are being used to identify nucleants and investigate orientation relationships with the Mg-matrix. This new understanding is then being applied to develop an improved grain refiner for Mg-Al based alloys.

Sihan Sun (Research Postgraduate)

Sihan Sun (Research Postgraduate)

My project focuses on the solidification process of Sn-based solders including SAC305 and some Sn-Ag solders as well as the undercooling – microstructure - performance relationships in them.

Weiqi Chen (Research Postgraduate)

Weiqi Chen (Research Postgraduate)

The microstructure of Intermetallic compounds (IMCs) plays a direct role in influencing the reliability of solder joints. However, due to the extensive usage of electronic equipment, solder joints are susceptible to various harsh environments. These environments include high temperatures and thermal cycling with significant temperature variations. Under such conditions, both isothermal and thermal cycling environments can lead to the coarsening of IMC, especially during the thermal cycling process. The differential coefficient of thermal expansion (CTE) between the substrate and the package may potentially explain the significant coarsening observed during the thermal cycling process. In the thermal cycling process, the substrate and package experience differential expansion due to varying CTE, resulting in different changes in length, which could stretch the solder joints between them. This process could potentially accelerate the IMC coarsening.

The aim of the project is to investigate the mechanism of IMC coarsening by comparing the particle size of the solder joints. This study will involve conducting isothermal tests and thermal cycling tests (without shear strength) to compare the particle size of solder joints. Subsequently, the study will further compare the particle size of solder joints within packages during thermal cycling tests (with shear strength).

Hongxuan Wang (Research Postgraduate)

Hongxuan Wang (Research Postgraduate)

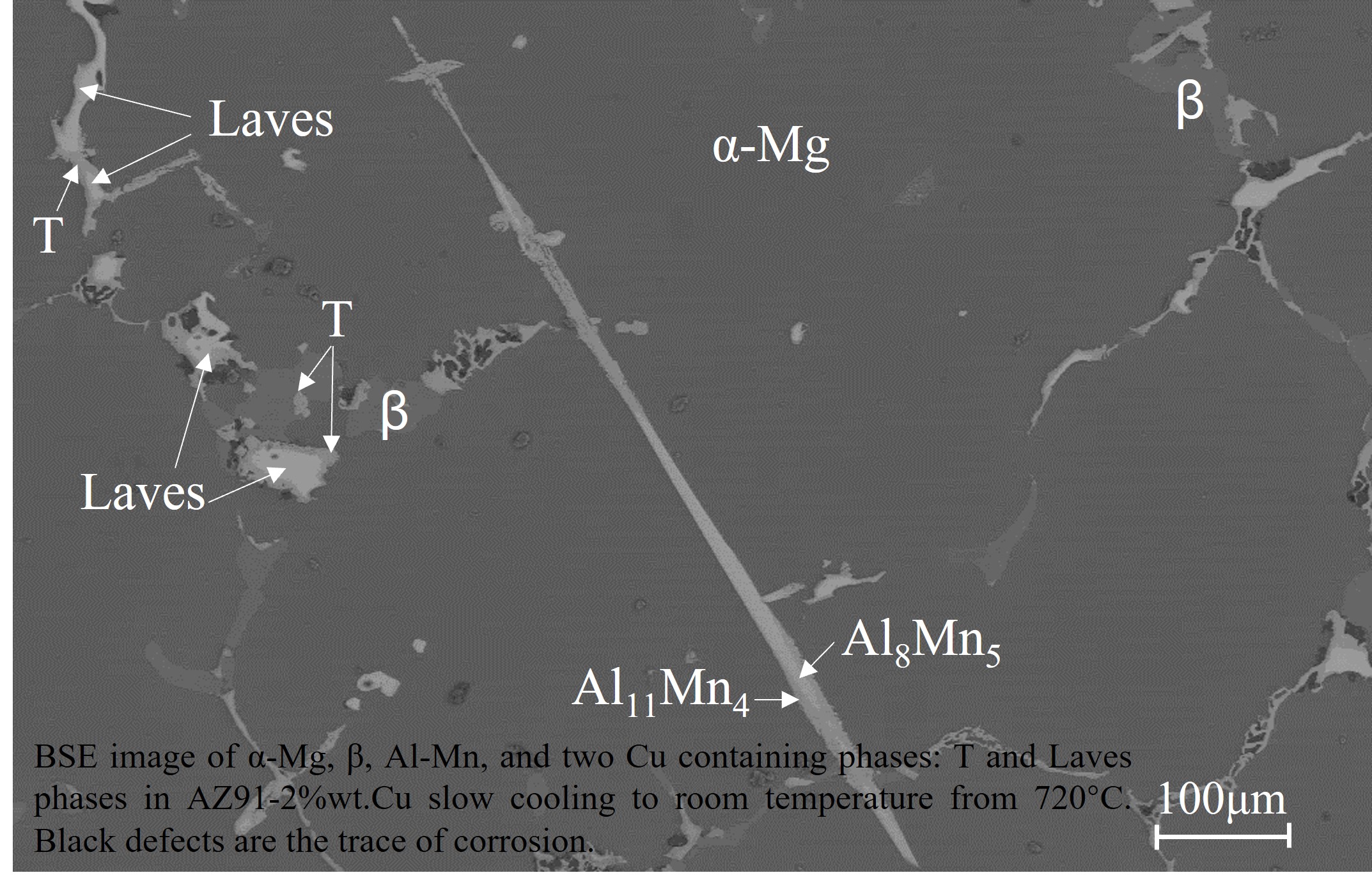

The possibility of removing Cu and Ni from the magnesium alloy melt is limited by high cost, so the aim of this project is to leave 0.5wt% Cu and 0.1wt% Ni impurities in the Mg alloy while still providing corrosion resistance similar to that of low-Cu commercial AZ91D alloy. To achieve this aim, we need to study the effect of copper in recycled magnesium alloys so that we can find solutions to reduce the negative effects of Cu.

The topics to be investigated are: (1) the effect of copper on the magnesium microstructure; (2) the formation and transformation of copper containing IMCs during solidification; (3) the effect of copper-containing IMCs on the corrosion and mechanical characteristics of the alloy; and (4) to develop an environmentally friendly alloy that is tolerant of 0.5%wt Cu and 0.1wt% Ni with low-cost. In this study, magnesium alloy AZ91 (Mg-9Al-0.7Zn-0.2Mn, wt%) is chosen as the base alloy.