Workshop Wizardry: new scheme at Imperial to train skilled research technicians

The College has recently revived an apprenticeship scheme to train technicians for the Faculty of Engineering and Department of Physics.

Scientific research today is nearly always a team effort – and is becoming increasingly collaborative and multidisciplinary. The popular image of a ‘lone genius’ working completely independently, usually in some isolated lab or shed, must surely be confined to the realms of fiction. Major discoveries are more likely to be the work of research groups which, in the case of genome projects and high energy physics programmes, may include hundreds of collaborators.

But even after acknowledging the immediate group of scientists, there is also an extended network of supporting players behind the scenes who work hard to make it all possible.

But even after acknowledging the immediate group of scientists, there is also an extended network of supporting players behind the scenes who work hard to make it all possible.

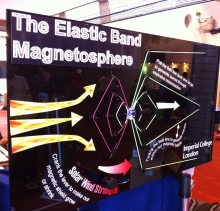

For the Faculty of Engineering and Department of Physics at Imperial, this includes a team of dedicated and skilled workshop technicians who manufacture all manner of bespoke equipment and parts for use in experiments. This can include casings for spacecraft destined for far-flung regions of the solar system; rigs to test how prosthetic limbs respond to forces; precision micrometre parts for laser experiments; and even outreach exhibits that tour science festivals and events around the country (see the image of the elastic band magnetosphere below).

If we stopped doing experimental work with top technicians who have learned their trade properly, we would be moving down the university rankings

– Stephen Richardson

Deputy Rector

So it’s vital that technician talent is recruited and nurtured, as Deputy Rector (and former Principal of the Faculty of Engineering and Head of the Department of Chemical Engineering) Professor Stephen Richardson points out:

“I know from experience that if it weren’t for two or three technicians, a whole line of work that I did in Chemical Engineering back then simply wouldn’t have been possible – you just can’t do it. If you can’t make kit that’s good enough you can’t do the experiments.

“If we stopped doing experimental work with top technicians who have learned their trade properly, we would be moving down the university rankings. We’ve just got to do this, and on a bigger scale than we are doing now.”

A couple of years ago Stephen was at a meeting of the College Court with two senior workshop supervisors, Paul Brown (Physics) and Russell Stracey (Materials), when they began to discuss the idea of a technician apprenticeship scheme.

A couple of years ago Stephen was at a meeting of the College Court with two senior workshop supervisors, Paul Brown (Physics) and Russell Stracey (Materials), when they began to discuss the idea of a technician apprenticeship scheme.

“We need such a diverse, skilled, sort of technician, that it makes sense to grow your own,” Paul says. “Of course, we’ve also recruited successfully from outside the College but this should be alongside growing your own talent.”

A technician apprenticeship scheme had run at Imperial until the early 1990s, but was wound down, partly because skilled technicians made redundant by manufacturing companies in the south east were becoming available. Also during the 1990s, school leavers with good grades were increasingly opting to go to university, so apprenticeships became somewhat unfashionable.

We need such a diverse, skilled, sort of technician, that it makes sense to grow your own

– Paul Brown

Mechanical Instrumentation Workshop Manager

That has all changed now and apprentices are very much in demand again from both the public and private sector, owing in part to an increased emphasis on ‘advanced manufacturing’ in the UK.

“Looking around at some of our more experienced technicians I think it’s fair to say we’re not getting any younger, so we identified a fairly pressing need,” says Russell.

Paul, Russell and Graeme Rae (a Department Operations Manager for Bioengineering) then fleshed out the details of the scheme in consultation with Human Resources and eight College departments: Aeronautics, Bioengineering, Chemical Engineering, Civil and Environmental Engineering, Earth Science and Engineering, Materials, Mechanical Engineering and Physics.

The idea was that apprentices would study for one year at Kingston College in Surrey – where apprentices from major UK companies such as BAA, Thames Water and TfL also come to study – then come back to Imperial to do six-month rotation placements around the different workshops.

“My vision was that they would come back to us ‘workshop safe’ so we wouldn’t then be giving them basic health and safety training but actually start teaching them their craft,” says Paul.

After setting up a steering group to put “some weight behind the scheme” they eventually recruited two apprentices in September 2011: Giovanni Marinaro and Robert Sherer.

On completing their first year at Kingston College in September 2012 the two began their workshop placements at Imperial in September last year.

“I always have been very hands-on; at school and college my favourite subjects were resistant materials and product design,” says Giovanni.

I’ve been to a few labs now, and every time it’s just blown my mind – you get a real sense of some of the exciting work they’re doing

– Giovanni Marinaro

Second year apprentice technician

“At college the main talk was about going to university, and I did look down that route, but I wasn’t 100 per cent sure, so I finished college and took a gap year. I then started an electrical installation apprenticeship with my uncle’s firm, which I enjoyed but I didn’t feel like I was quite pushing myself enough. So I then researched apprenticeships in more depth and found the Imperial scheme which looked like a really interesting challenge.”

During the course of the autumn term, Giovanni spent time in the Physics workshop in the basement of the Blackett Building, getting to know the machines and also a little about the research that the Department gets up to.

“I’ve been to a few labs upstairs now, and every time it’s just blown my mind. I don’t fully understand all the science behind it – but you get a real sense of some of the exciting work they’re doing.”

One project he particularly enjoyed involved working with PhD student Jessica Wade (Physics). The research group in which Jessica is based (under the supervision of Dr Ji-Seon Kim) builds electrical and optical devices such as advanced LEDs, transistors and solar cells. The group decided that they needed a rig with which they could test these devices to see how well they operated under strict experimental conditions.

“Giovanni is building us a chamber which can be filled with nitrogen and allows our samples to be mounted and electrically contacted. The unique design of Giovanni’s chamber allows us to easily move between different devices,” Jessica says.

Meanwhile, Robert spent his first six months at Imperial in the Aeronautics workshopmaking components on the machines and also working on some of the wind tunnels and highly specialised facilities the Department of Aeronautics uses. He even made some components that were fired together at high velocity and vaporised in the Institute of Shock Physics’ gas gun, a facility that helps to understand how materials cope under extreme forces.

Meanwhile, Robert spent his first six months at Imperial in the Aeronautics workshopmaking components on the machines and also working on some of the wind tunnels and highly specialised facilities the Department of Aeronautics uses. He even made some components that were fired together at high velocity and vaporised in the Institute of Shock Physics’ gas gun, a facility that helps to understand how materials cope under extreme forces.

“The tolerances they have to work within there are extremely fine, because obviously these parts are eventually destined for critical applications in aircraft or cars for example,” he says.

When the technician apprenticeship scheme is ‘fully loaded’ there will be eight trainee technicians at any one time at various stages of their four-year training programme (two in each year). Stephen Richardson is keen to stress that the scheme is not only about what the apprentices can offer Imperial, but what the scheme can offer them in terms of career development.

“It’s good for us and good for them, because they get experience of very up-to-date, precision machinery and computer control software – it’s an investment across the board,” he says.

During their time at Kingston College and the Imperial workshops, the apprentices work towards qualifications at various levels including the National Vocational Qualification (NVQ); BTEC; Higher National Certificate (HNC); and Higher National Diploma (HND).

“At the end of the four years, the apprentices will have to find jobs, but they’ll be well known around the Departments and so if there’s a role going they will hopefully be in a very strong position,” says Russell.

Technicians can go on to do degrees, as did senior technician Guljar Singh (Mechanical Engineering). He went through an apprenticeship at Imperial as part of the original scheme back in the 1990s, and then did a part-time degree in Mechanical Engineering while working as a technician.

Technicians can also specialise in various different workshop areas, such machine tooling, design and electronics to name a few. Peter Savage (Physics), a Project Engineer for the High Energy Physics Group, works extremely closely with scientists and is currently involved in the design of a proton accelerator at the Rutherford Appleton Laboratories in Oxford.

Indeed, much of the scientific research we hear about so often in the media is made possible thanks to the behind-the-scenes work of the technicians, even if it’s seldom acknowledged. Whichever path the apprentices ultimately decide to take, they will no doubt contribute to the discoveries and technologies of the not too distant future.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Andrew Czyzewski

Communications Division