Sustainable way to make breast cancer drug could boost South African production

Imperial researchers have devised a cheaper, more efficient, and sustainable way to produce a breast cancer drug in South Africa.

The method is designed to facilitate the development of local pharmaceutical manufacturing capabilities in South Africa that could serve the country and its neighbours.

We were able to find a more efficient way to manufacture lapatinib ... greatly reducing the cost and improving access to this lifesaving drug. Professor Mimi Hii

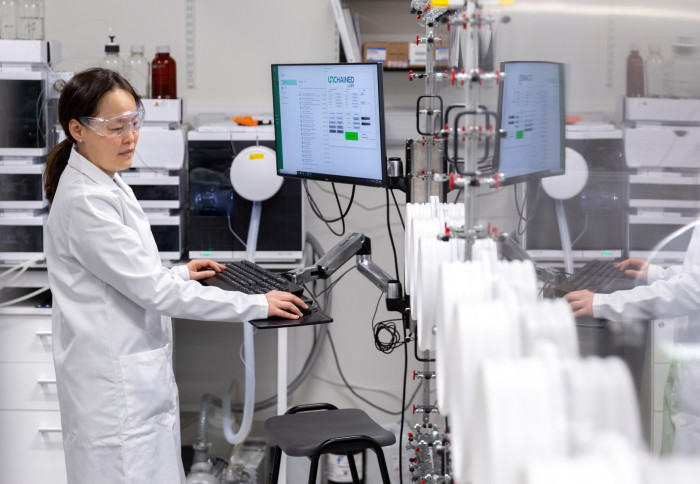

The breast cancer drug is the first proof of concept for Imperial’s Centre for Rapid Online Analysis of Reactions (ROAR), which uses automation to gather data about reactions in order to optimise the production of useful molecules like drugs. The team hope their findings will lead to South Africa becoming more independent in drug production, which could help reduce medicine costs and thwart shortages.

Breast cancer is the fifth leading cause of cancer mortality worldwide, and is increasing in sub-Saharan countries. While existing drugs can tackle many breast cancer cases, these can be expensive and are not as readily available in low- and middle-income countries.

Now, researchers from Imperial’s ROAR, based in the Department of Chemistry, have collaborated with scientists in South Africa to create a new way to synthesise a key breast cancer drug called lapatinib. The method, published in Reaction Chemistry & Engineering, uses fewer environmentally toxic chemicals and less energy.

Improving access

The study includes an analysis performed by Department of Chemical Engineering researchers that shows how this approach can be adopted in South Africa. As a result, the South African team are currently working on demonstrating the process at scale.

Lead researcher and Director of ROAR Professor Mimi Hii, from the Department of Chemistry at Imperial, said: “Lapatinib is a potent anti-cancer drug, but because it is produced in small quantities, it is traditionally expensive and not widely available through public healthcare in South Africa and neighbouring countries.

“Using our automated reaction system, we were able to find a more efficient way to manufacture lapatinib that should be relatively easy to set up within the country, greatly reducing the cost and improving access to this lifesaving drug.”

Co-investigator from the CSIR in South Africa, Dr Jenny-Lee Panayides, said: “Working with the Imperial team on the lapatinib process has provided a wonderful opportunity for knowledge exchange, with key skills being transferred from ROAR to the South African team that can support the leap-frogging application of flow technology for future manufacturing active pharmaceutical ingredients in the local context.”

Automatic chemistry

ROAR aims to bridge the gap between discovery in academic labs and industrial-scale production. Labs may be able to produce tens of grams of a substance in a repeatable way, but when this is scaled up to kilogram-level production, some reaction steps may not perform as expected.

To overcome this scaling problem, ROAR uses a system of automatic reaction and testing setups, allowing the researchers to collect and analyse much more data about every step of the reaction and the instrument conditions.

Not only can this help researchers find the reaction conditions that produce the desired molecules with the least energy and environmentally toxic chemicals, but the precise data collected means the process can more easily be replicated elsewhere.

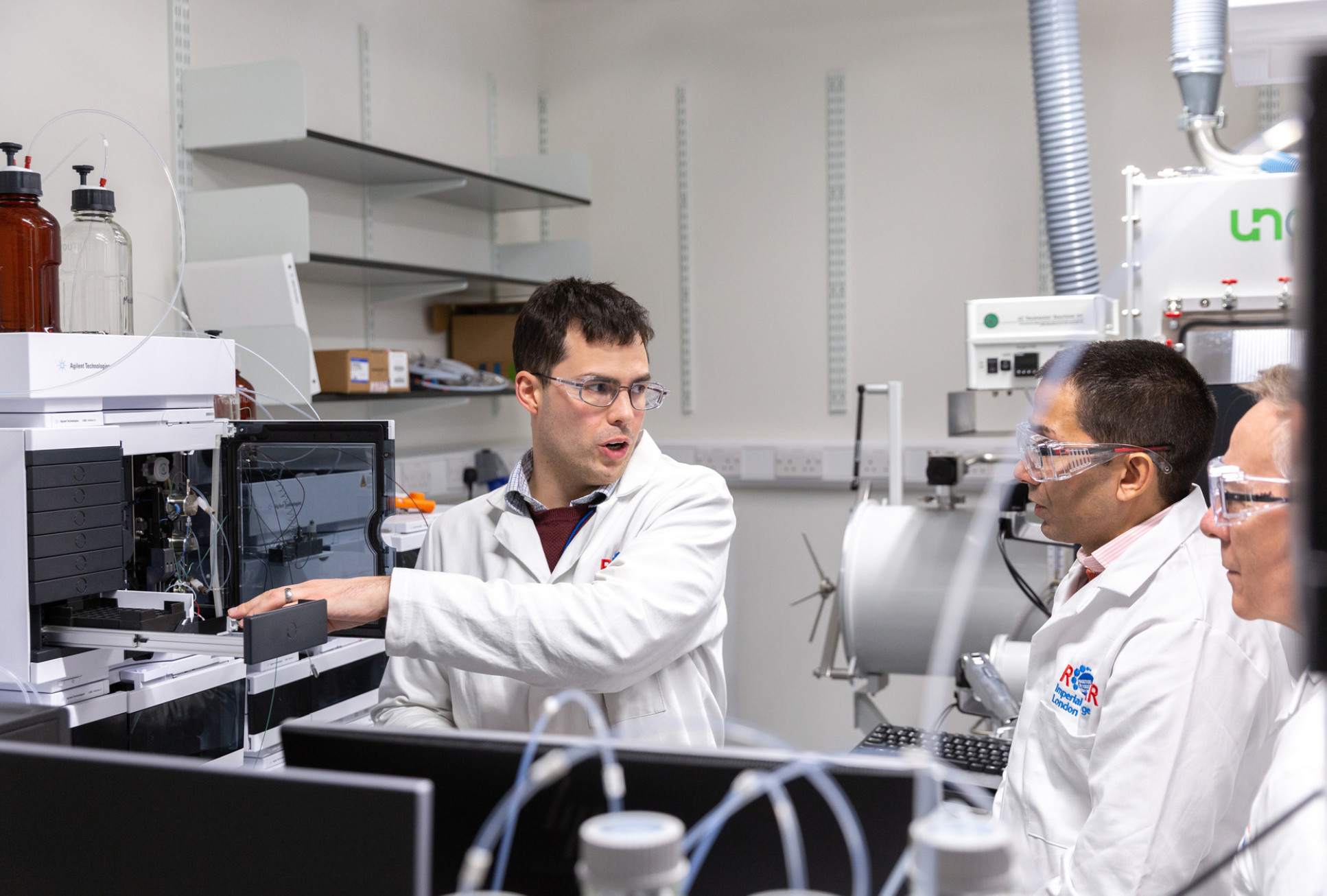

ROAR Facility Manager Dr Ben Deadman said: “Without ROAR, determining how to make these drugs cheaply and sustainably would take much longer. Our system means sustainability and manufacturability are built in from the start, rather than the usual two-step process of discovery and upscaling.

“This project is the perfect example of what we can do with ROAR and we hope it will lead to many more such collaborations. Not only have we been able to find a better drug production route, but we have collaborated with South African chemists to share knowledge and train workers in advanced chemical techniques that will enable a home-grown drug industry to thrive in the country.”

Expanding approaches

The project was funded by the UK Government’s Global Challenges Research Fund, which supported cutting-edge research that addresses the challenges faced by developing countries.

Now the team have shown the value of their approach, they are hoping to expand it to other types of drugs that are of relevance to the African market, such as antiretrovirals, antibiotics and treatments for neglected diseases, and vital components of drugs known as active pharmaceutical ingredients (APIs).

Advanced chemical manufacture techniques can also reduce some supply issues. For example, many reactive chemicals needed for manufacturing must be carefully shipped using expensive logistics routes. Modern methods can instead produce these reactive chemicals on-site from inactive chemicals, reducing the costs and risks of transport.

-

‘Assessing a sustainable manufacturing route to lapatinib’ by Roderick T. Stark et al. is published in Reaction Chemistry & Engineering.

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Hayley Dunning

Communications Division