Battery ageing models will help stretch the green benefits of electric vehicles

by Ian Mundell

The About:Energy team

A battery modelling project led by Imperial startup About:Energy promises to lower the ownership cost and carbon footprint of electric vehicles.

We all know that smartphone batteries are not forever. Their ability to stay charged gradually declines and then, without warning, it drops dramatically. The same goes for the lithium-ion batteries used in electric vehicles and other safety critical applications. Accurately predicting how such batteries age and decline is the goal of a £1 million Faraday Battery Challenge project led by Imperial startup About:Energy, which will also support researchers from the Electrochemical Science and Engineering (ESE) group.

Observing a battery’s performance as it ages will tell you something about its potential lifetime, but this is a long, drawn-out process, and extrapolating beyond the measurements is not very reliable. This is where a detailed understanding of battery electrochemistry can help.

“One of the approaches that Imperial has pioneered in recent years involves modelling the individual processes within the battery, and looking at how it degrades electrochemically,” says Dr Yatish Patel, an ESE group member in the Department of Mechanical Engineering, who is leading the research.

“We can observe phase changes in the materials, and we can link those back to individual degradation processes within the battery. And this allows us to predict that degradation much more accurately, and to go beyond the testing boundaries.”

Life models

The aim of the Faraday Battery Challenge project, which is still subject to final approval, is to use this knowledge to build advanced computer models that companies can use to predict the lifetime of different batteries, in different situations. This is where About:Energy comes in.

The company was set up in 2021 by Gavin White from Imperial and Kieran O’Regan from the University of Birmingham, who met as PhD students on the Faraday Institution’s Multi-scale Modelling Project, led by ESE’s Professor Greg Offer. Their idea was to provide software and data services that would enhance battery development and application in the automotive, aerospace and other sectors.

Since then, About:Energy has built up a huge store of data about commercially available batteries, and constructed models that can help companies select cells and design systems that optimise their performance. But these models all assume that the batteries are new. Being able to factor in ageing would be a valuable addition. “Battery lifetime is a metric that should be included at the design stage, but that currently doesn’t happen because of the difficulty of modelling the processes involved,” says Mr O’Regan, Chief Operating Officer at About:Energy.

Pick your processes

Five or six different degradation processes may be at work within a battery as it ages, but modelling all of these would be extremely costly in terms of computing power. So the idea is to identify the two or three most important processes, and concentrate on those.

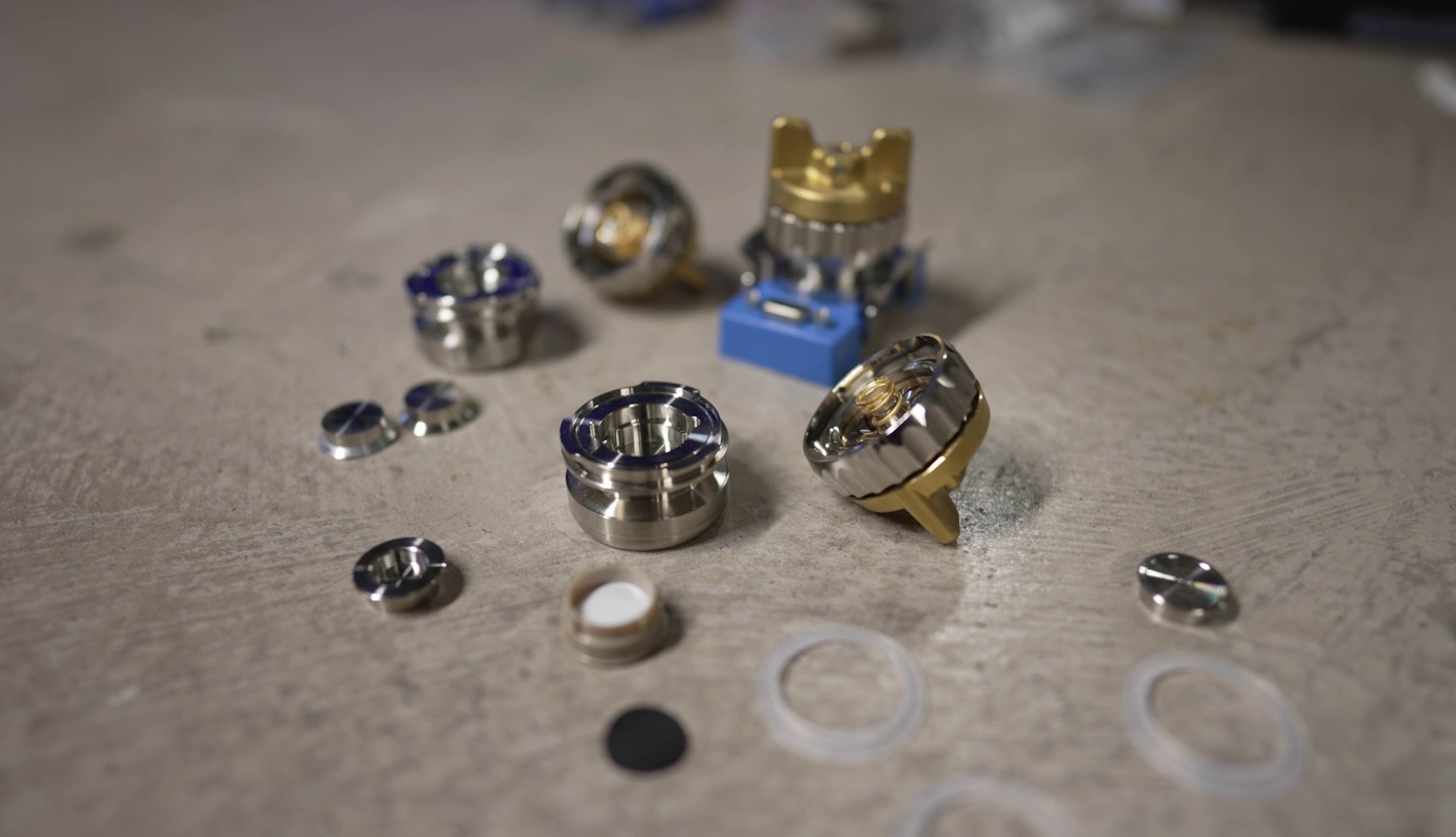

In order to do this, About:Energy will combine the cell-level degradation data provided by the Imperial researchers to its own expertise in battery forensics, dismantling cells to see which degradation processes have been at work on the electrodes inside.

“Through the cell-level tests and the battery tear-downs, we can observe the primary degradation mechanisms for specific cell types in a given application. Those are the ones that we can then focus on modelling,” says Mr O’Regan. “This will allow us to find more accurate and cost-effective approaches to modelling battery ageing.”

Designed for longer life

These models will help companies improve battery management systems, and make better decisions around vehicle design. “Designing for battery lifetime, not just energy and power, provides a route to improving total cost of ownership and the carbon footprint of battery systems,” Mr O’Regan says.

Designing for battery lifetime provides a route to improving total cost of ownership and carbon footprint. Kieran O'Regan About:Energy

These tools also enable better planning at the end of a battery’s life by predicting when they may have to be retired from critical uses in vehicles, but still have enough capacity to be used in other applications, such as grid storage.

As the Faraday Battery Challenge project progresses, the models that About:Energy develops will be evaluated and exploited by Arrival, a UK-based manufacturer of commercial electric vehicles, with the goal of improving the operational lifetime.

“Understanding battery degradation is crucial to improve reliability of electric vehicles,” said Dr Trishna Raj, Battery Data Scientist at Arrival. “Predicting battery lifetime under various operating conditions aids in improving pack design and providing warranties to our customers.”

Meanwhile, About:Energy is about to launch its software platform The Voltt, which will provide access to data and models for hundreds of commercial and bespoke batteries. This will allow organisations to streamline their R&D with battery data that would otherwise require substantial engineering expertise and overhead to acquire.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Ian Mundell

Enterprise