This project focuses on impressing patterns on polymeric substrates via wrinkling. Wrinkles functionalise surfaces by changing their adhesion, liquid spreading properties and light harvesting properties.

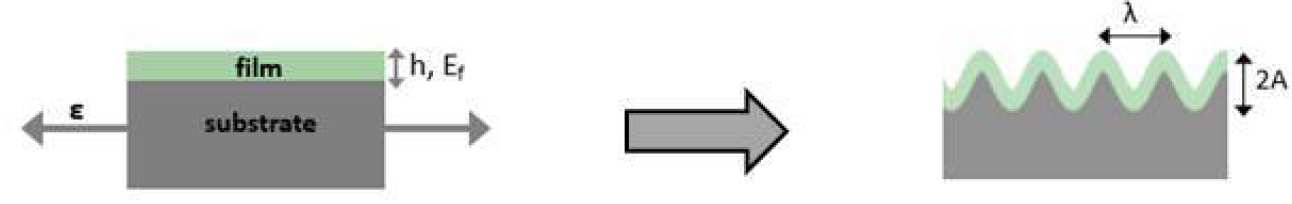

Wrinkling can occur when a bi-(or multi) layer is subject to mechanical strain. If the layers have different mechanical properties, upon compression the mismatch causes instabilities which result in pattern formation. Depending on the strain applied, a variety of patterns can be observed: between these we are interested in ordered sinusoidal patterns.

Our research focuses on determining the limits of wrinkling for nanoscale patterning. Moreover we are also interested in applying this patterning method, for example to characterise films in terms of their mechanical properties.

References

6. Nania, M., Foglia, F., Matar, O. and Cabral, J. T. (2017), Sub-100 nm wrinkling of polydimethylsiloxane by double frontal oxidation, Nanoscale, 9, 2030-2037

5. Nania, M. (2017), Scalable soft matter patterning from the macro to the nanoscale, PhD Thesis, Imperial College London

4. Ferretti, G.*, Nania, M.*, Matar, O. K. And Cabral, J. T. (2016) Wrinkling measurement of the mechanical properties of drying salt thin films. Langmuir, 32, 9, 2199-2207

3. Nania, M., Matar, O.K. and Cabral, J.T. (2015) Frontal vitrification of PDMS using air plasma and consequences for surface wrinkling. Soft Matter, 11, 3067-3075.

2. Chiche, A., C.M. Stafford, and J. Cabral (2008) Complex micropatterning of periodic structures on elastomeric surfaces. Soft Matter, 4, p. 2360-2364.

1. Bayley, F.A., et al. (2014), Wavefront kinetics of plasma oxidation of polydimethylsiloxane: limits for sub- μm wrinkling. Soft Matter, 10, p. 1155-1166.