Innovation across the UK

Key facts

- Innovation is core to Imperial: In 2022/23, Imperial academic and student start-ups attracted an estimated £267 million in external investment and were supporting 5,519 jobs (HESA HE-BCI 22/23).

- Imperial is one of the most collaborative institutions in the UK, between 2017 and 2021, we shared research awards with over 600 and co-authored publications with around 800 UK organisations all over the UK.

-

White City Campus is home to 73 companies ranging from startups to scaleups to large corporations and companies growing from the White City Incubator created over 480 jobs and raised over £460m since 2016.

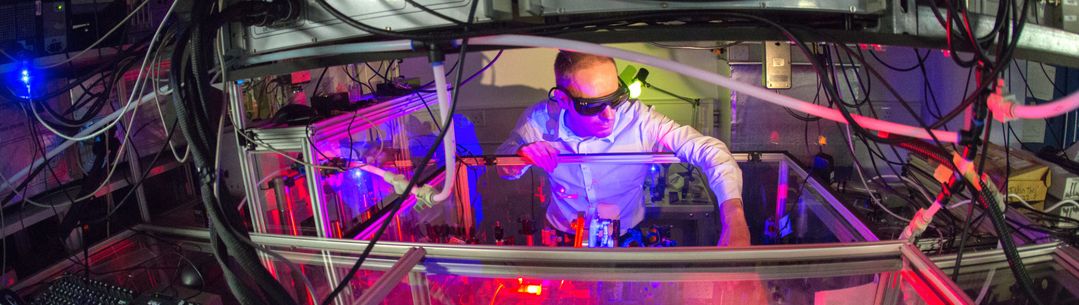

Through our academic, industry and community partnerships Imperial has an impact well beyond our campuses: our interactive impact map demonstrates how science, innovation and skills generated at Imperial have an impact across the UK. Our White City innovation ecosystem supports entrepreneurial staff and students, and industry partners, to move cutting-edge research into ideation, incubation and growth settings – creating impact in London and beyond:

- Imperial start up Impression Technologies Limited is making the next generation of green cars more efficient, replacing steel with aluminium using an innovative and patent protected technology. Impression Technologies successfully raised £6m investment to create a production facility in Coventry which employs 45 people in highly-skilled roles.

- Imperial start-up Fresh Check has produced the first affordable test for surface contamination with a simple colour changing spray. Utilising facilities in Peterborough and Carmarthenshire, Fresh Check are creating new products which will be made in the UK and exported globally. Simpler hygiene verification will make it easier for UK SMEs employing 135,000 in the food/drink sector to expand.

-

Co-founded by four Imperial graduates, Ponda has created a product called BioPuff which is a plantbased fibre that can be used as an alternative to goose-down or synthetics. Using BioPuff to fill jackets can saves 25 litres of water reduce petroleum usage by 70% per jacket. Headquartered in Bristol and with a manufacturing facility in Scotland, SaltyCo’s agricultural practices are focused on regenerating the environment with projects in North Berwick and Cambridgeshire.