The study of transport processes is key to countless applications from multiphase flow in pipelines to boiling flows in concentrating solar power plants and combustion in engines. Understanding the fundamental phenomena of fluid mechanics, mass transfer and heat transfer associated with such systems informs their efficient design and operation, translating to tangible improvements in performance. In the Transport Processes Division, advanced experimental methods including state-of-the-art optical techniques are employed to gain insights into transport phenomena through detailed measurements with high spatial and temporal resolution.

The research activities conducted by the Transport Processes Division are:

- Multiphase/Interfacial flows.

- Heat transfer.

- Phase change.

- Chemically-reacting flows.

- Complex fluids, heat transfer enhancement and drag reduction.

Transport Processes Division Content

- 1. Multiphase/interfacial flows

- 2. Heat transfer

- 3. Phase change

- 4. Chemically-reacting flows

- 5. Complex fluids, heat transfer enhancement and drag reduction

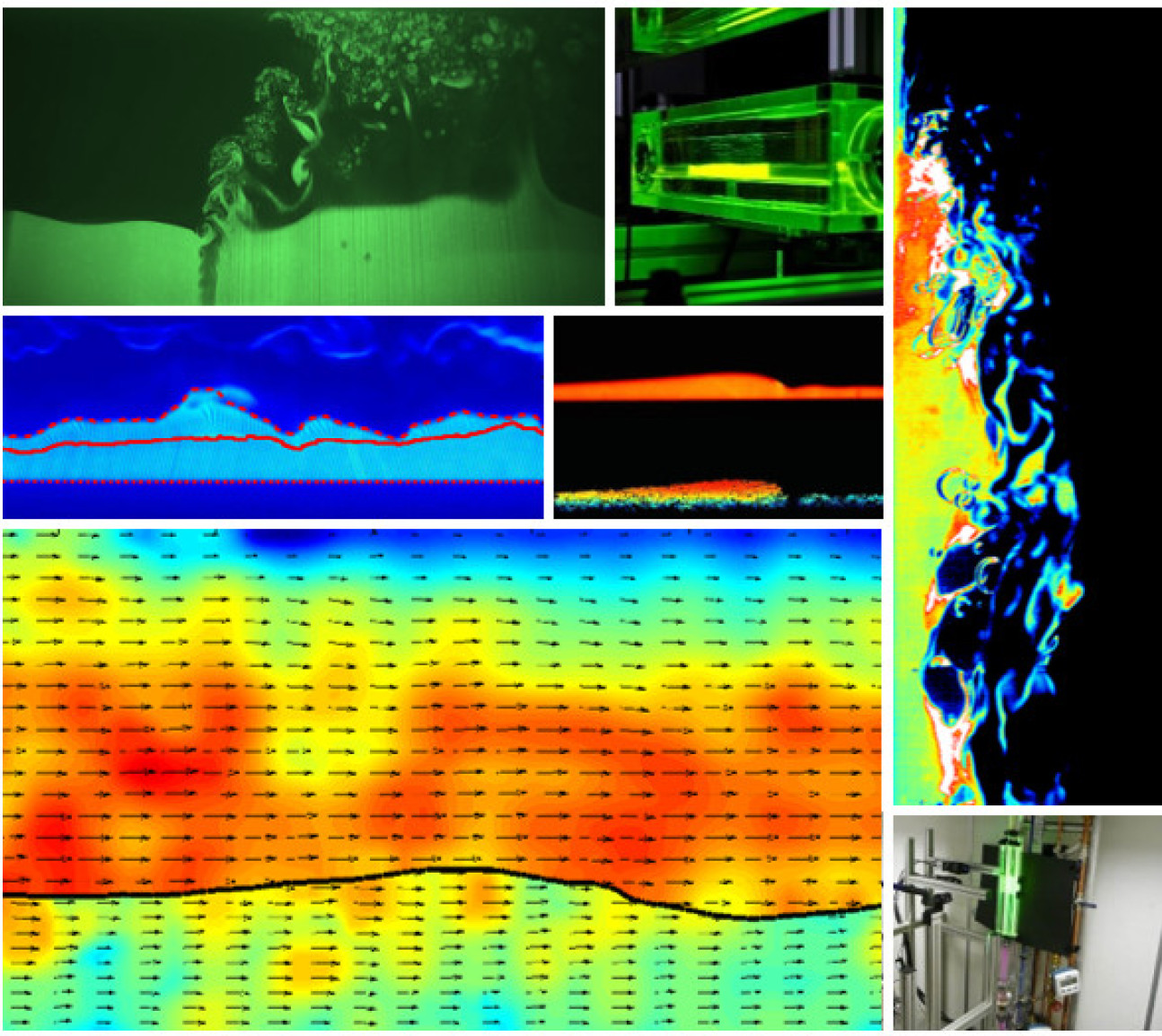

Adiabatic two-phase, thin-film and jet flows

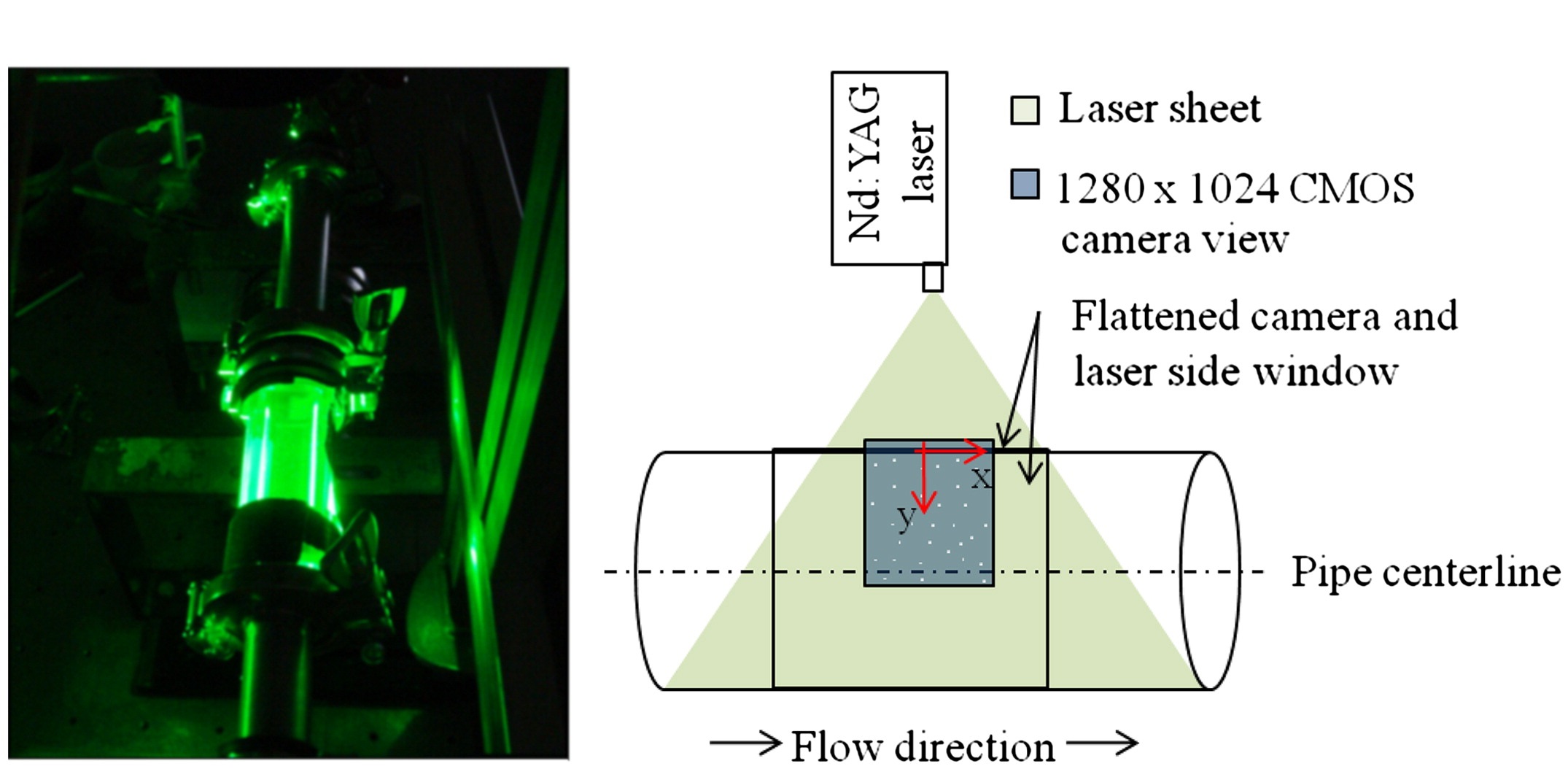

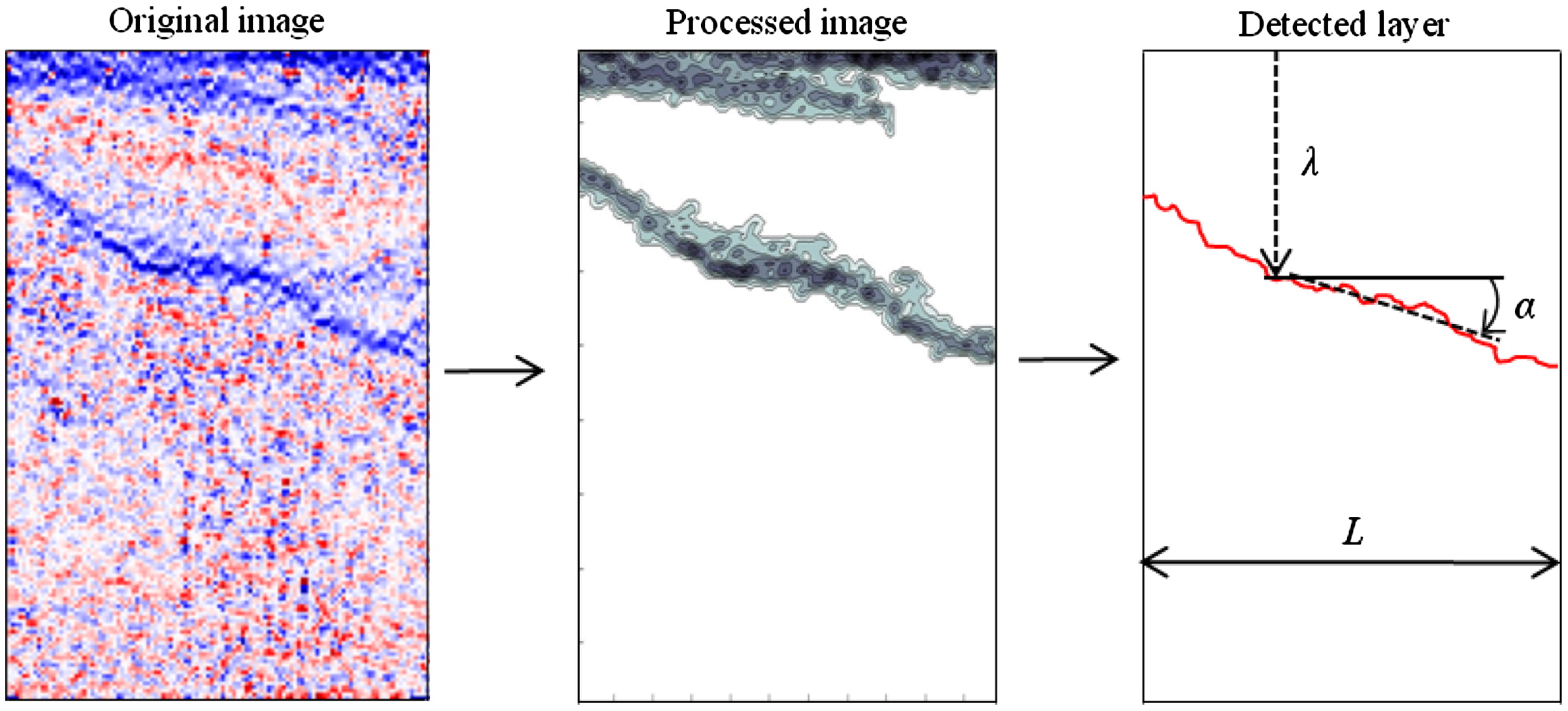

This theme focuses primarily on the development and implementation of advanced experimental methods to characterise, via spatiotemporally resolved measurements, falling films, jet flows, as well as various regimes and patterns (e.g., annular, slug, stratified) of horizontal and vertical two- and three-phase pipe flows in lab- and pilot-scale size rigs. The flows are investigated at the test section, primarily with the application of optical diagnostic methods, which include combinations of:

This theme focuses primarily on the development and implementation of advanced experimental methods to characterise, via spatiotemporally resolved measurements, falling films, jet flows, as well as various regimes and patterns (e.g., annular, slug, stratified) of horizontal and vertical two- and three-phase pipe flows in lab- and pilot-scale size rigs. The flows are investigated at the test section, primarily with the application of optical diagnostic methods, which include combinations of:

-

Planar Laser-Induced Fluorescence (PLIF),

- Structured-Planar Laser-Induced Fluorescence (S-PLIF),

-

Brightness-Based Laser-Induced Fluorescence (BBLIF),

-

Particle Image Velocimetry (PIV),

-

Stereo-Particle Image Velocimetry (S-PIV),

-

Particle Tracking Velocimetry (PTV), and

-

Tomographic Dual-Beam X-Ray Imaging.

These techniques allow the reliable evaluation of the nature of the investigated two-phase flows (i.e., the flow patterns/regimes from phase distribution information), together with the detailed spatiotemporally resolved measurement of key flow properties, such as phase/concentration and velocity distributions, and also of important parameters such as droplet size and wave characteristics.

Selected publications:

- A. Charogiannis, J. S. An, V. Voulgaropoulos, C. N. Markides, 2019. Structured planar laser-induced fluorescence (S-PLIF) for the accurate identification of interfaces in multiphase flows. International Journal of Multiphase Flow 118: 193. doi.org/10.1016/j.ijmultiphaseflow.2019.06.002.

- A. V. Cherdantsev, J. S. An, A. Charogiannis, C. N. Markides, 2019. Simultaneous application of two laser-induced fluorescence approaches for film thickness measurements in annular gas-liquid flows. International Journal of Multiphase Flow 119: 237. doi.org/10.1016/j.ijmultiphaseflow.2019.07.013.

- R. Ibarra, I. Zadrazil, O. K. Matar, C. N. Markides, 2018. Dynamics of liquid-liquid flows in horizontal pipes using simultaneous two-line planar laser-induced fluorescence and particle velocimetry. International Journal of Multiphase Flow 101: 47. doi.org/10.1016/j.ijmultiphaseflow.2017.12.018.

- A. Charogiannis, J. S. An, C. N. Markides, 2015. A simultaneous planar laser-induced fluorescence, particle image velocimetry and particle tracking velocimetry technique for the investigation of thin liquid-film flows. Experimental Thermal and Fluid Science 68: 516-536. doi.org/10.1016/j.expthermflusci.2015.06.008.

- I. Zadrazil, C. N. Markides, 2014. An experimental characterization of liquid films in downwards co-current gas–liquid annular flow by particle image and tracking velocimetry. International journal of Multiphase Flow 67: 42. doi.org/10.1016/j.ijmultiphaseflow.2014.08.007.

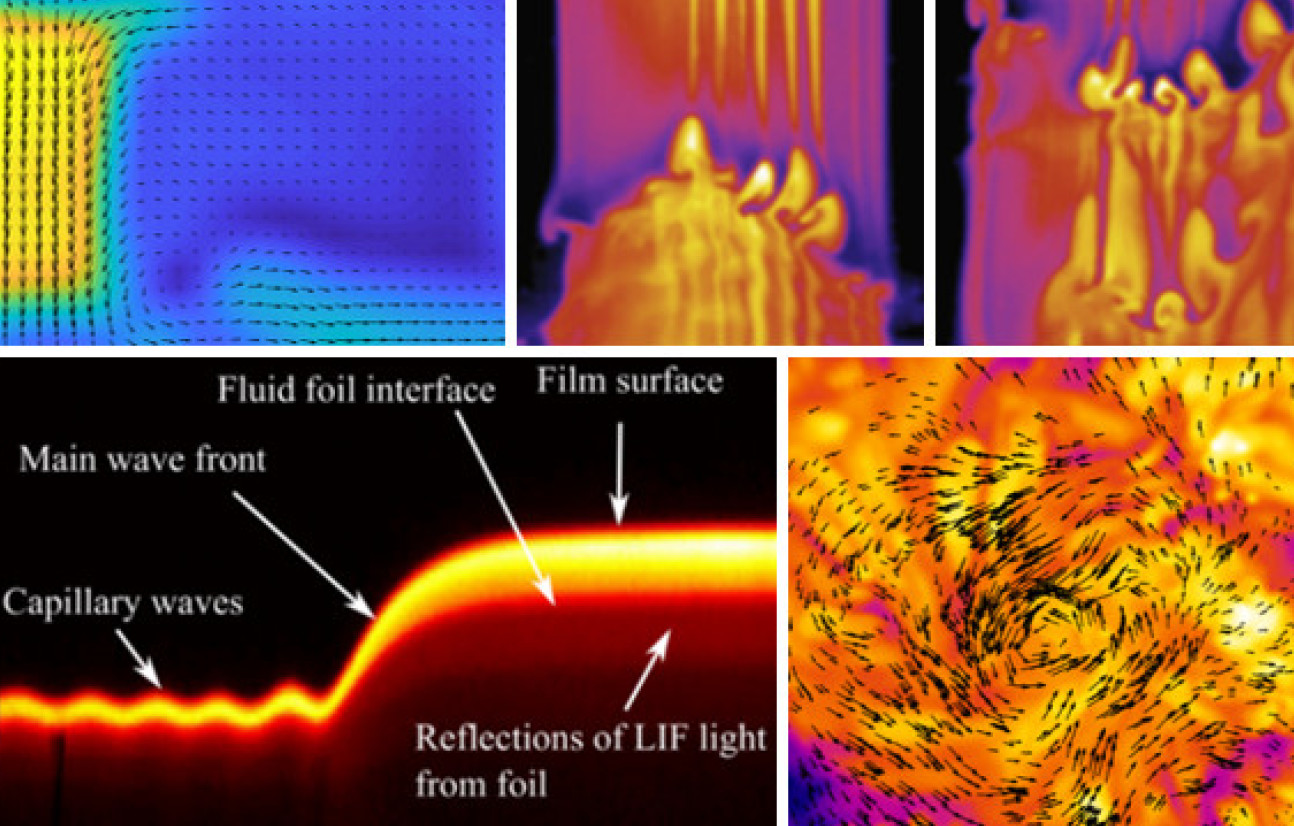

Falling films, two-phase and free-surface flows

Many energy conversion and other thermal-fluid systems exhibit unsteady convective heat exchange. In such systems, generic spatiotemporal variations in the flow give rise to variations in the heat flux for a given fluid–solid temperature difference, which can be interpreted as spatiotemporal fluctuations of the instantaneous heat transfer coefficient. This theme is concerned with the phenomenon of heat transfer augmentation in unsteady and conjugate fluid–solid systems and with the development and application of advanced diagnostic methods (e.g., infrared thermography (IR-T), thermographic particle velocimetry (TPV), laser-induced fluorescence thermography (LIF-T)) to allow for detailed and unprecedented measurement capabilities. The findings can be used in the design of improved heat exchangers or thermal insulation, for example through the novel selection of materials that can exploit these augmentation effects.

Selected publications:

- A. Charogiannis, C. N. Markides, 2019. Spatiotemporally resolved heat transfer measurements in falling liquid-films by simultaneous application of planar laser-induced fluorescence (PLIF), particle tracking velocimetry (PTV) and infrared (IR) thermography. Experimental Thermal and Fluid Science 107: 169. doi.org/10.1016/j.expthermflusci.2018.11.001.

- A. Charogiannis, F. Denner, B. G. M. van Wachem, S. Kalliadasis, C. N. Markides, 2017. Spatiotemporally resolved heat transfer in falling-film flows by laser-induced fluorescence, particle tracking velocimetry and infrared thermography. 2nd Thermal and Fluid Engineering Conference, TFEC2017. At: Las Vegas, Nevada. doi.org/10.1615/TFEC2017.tpd.017771.

- A. Charogiannis, I. Zadrazil, C. N. Markides, 2016. Thermographic particle velocimetry (TPV) for simultaneous interfacial temperature and velocity measurements. International Journal of Heat and Mass Transfer 97: 589. doi.org/10.1016/j.ijheatmasstransfer.2016.02.050.

- C. N. Markides, R. Mathie, A. Charogiannis, 2016. An experimental study of spatiotemporally resolved heat transfer in thin liquid-film flows falling over an inclined heated foil. International Journal of Heat and Mass Transfer 93: 872. doi.org/10.1016/j.ijheatmasstransfer.2015.10.062.

- R. Mathie, H. Nakamura, C. N. Markides, 2013. Heat transfer augmentation in unsteady conjugate thermal systems – Part II: Applications. International Journal of Heat and Mass Transfer 56: 819. doi.org/10.1016/j.ijheatmasstransfer.2012.09.017.

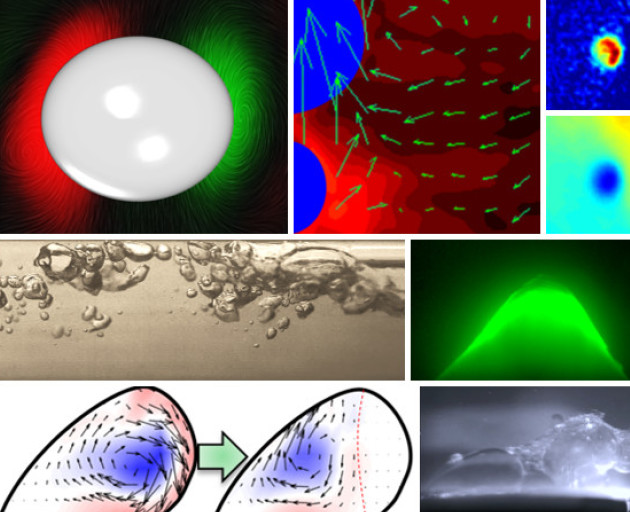

Freezing and boiling in pool or flow conditions

Investigations of pool and flow boiling, as well as freezing under natural and forced convection are performed within the framework of this theme. Phase change involves a plethora of complex and interacting flow, heat transfer and thermodynamic mechanisms, which we aspire to shed light on by developing and employing a multitude of spatiotemporally resolved diagnostic measurement tools. Apart from investigations answering questions of fundamental nature, we also tackle industrial challenges encountered in state of the art energy processes, e.g., direct steam generation in concentrated solar power plants, hydrate formation, nuclear reactor cooling and accident prevention, organic Rankine cycles, heat exchanger fouling, thermal (latent heat) energy storage applications.

Investigations of pool and flow boiling, as well as freezing under natural and forced convection are performed within the framework of this theme. Phase change involves a plethora of complex and interacting flow, heat transfer and thermodynamic mechanisms, which we aspire to shed light on by developing and employing a multitude of spatiotemporally resolved diagnostic measurement tools. Apart from investigations answering questions of fundamental nature, we also tackle industrial challenges encountered in state of the art energy processes, e.g., direct steam generation in concentrated solar power plants, hydrate formation, nuclear reactor cooling and accident prevention, organic Rankine cycles, heat exchanger fouling, thermal (latent heat) energy storage applications.

Selected publications:

- V. Voulgaropoulos, G. M. Aguiar, O. K. Matar, M. Bucci, C. N. Markides, 2019. Temperature and velocity field measurements of pool boiling using two-colour laser-induced fluorescence, infrared thermometry and particle image velocimetry. 10th International Conference on Multiphase Flow, ICMF2019. At: Rio de Janeiro, Brazil. hdl.handle.net/10044/1/68411.

- H. Moran, V. Voulgaropoulos, D. Zogg, O. K. Matar, C. N. Markides, 2019. Experimental observations of flow boiling in horizontal tubes for direct steam generation in concentrating solar power plants. 16th UK Heat Transfer Conference, UKHTC2019. At: Nottingham, UK. doi.org/10.1007/978-981-33-4765-6_32.

- V. Voulgaropoulos, K. R. Kumar, A. Sudha, P. Sapin, S. F. Wright, O. K. Matar, C. N. Markides. 2019. An experimental investigation of droplets freezing in a horizontal two-phase pipe flow. 10th International Conference on Multiphase Flow, ICMF2019. At: Rio de Janeiro, Brazil.

- N. Le Brun, A. Charogiannis, G. F. Hewitt, C. N. Markides, 2017. Tackling Coolant Freezing in Generation-IV Molten Salt Reactors. 25th International Conference on Nuclear Engineering. At: Shanghai, China. doi.org/10.1115/ICONE25-67984.

- N. Le Brun, G. F. Hewitt, C.N. Markides, 2017. Transient freezing of molten salts in pipe-flow systems: Application to the direct reactor auxiliary cooling system (DRACS). Applied Energy 186: 56. doi.org/10.1016/j.apenergy.2016.09.099.

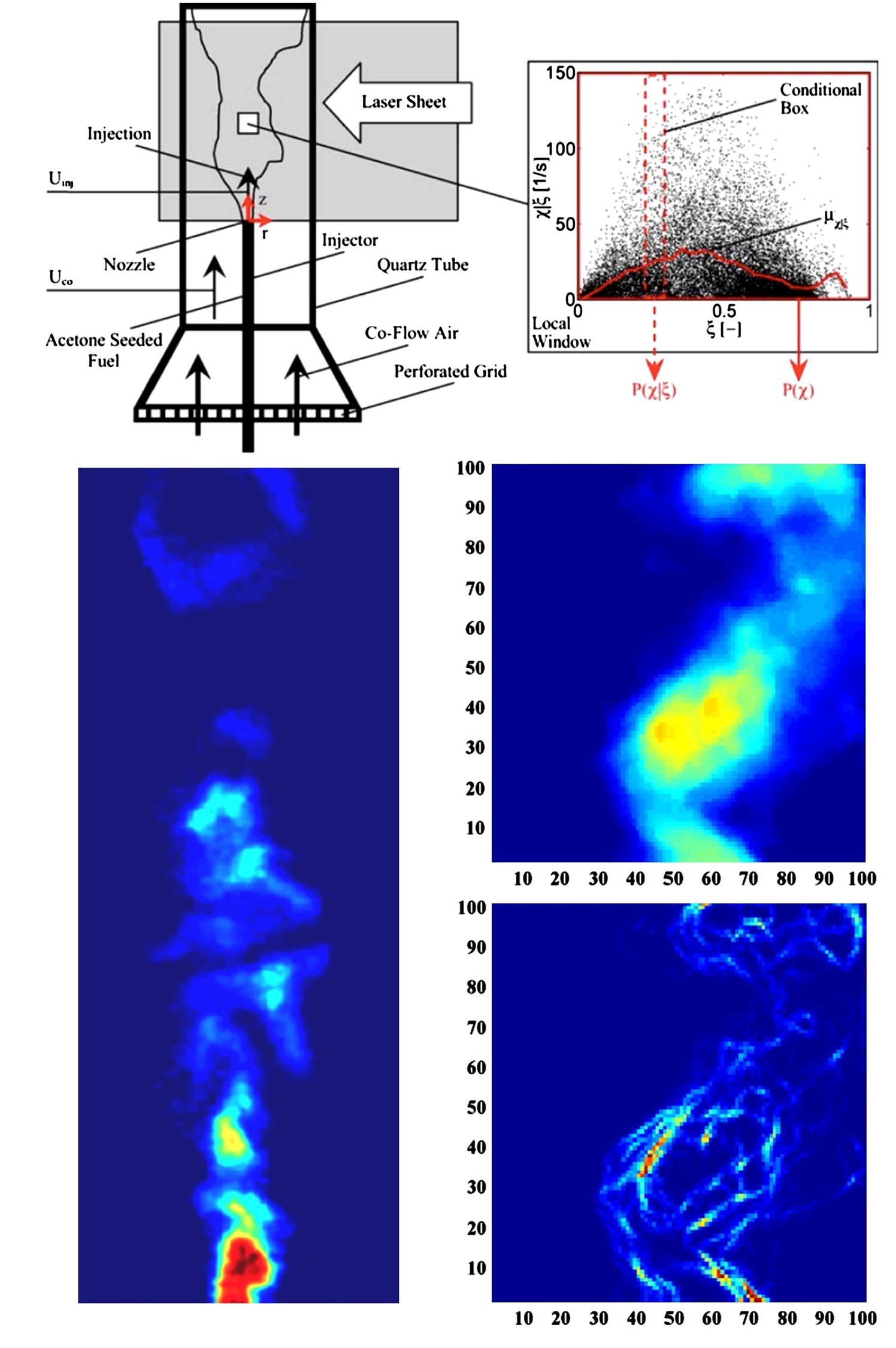

Turbulent inhomogeneous autoignition of liquid fuels, and micro-combustion

Autoignition is a multi-physics phenomenon that occurs in wide-ranging engineering applications, such as diesel engines, gas turbines and jet-engine afterburners. In these applications, autoignition occurs in the presence of flow inhomogeneities and turbulence. Liquid fuel autoignition presents a case of chemically reacting flow where processes such as jet break-up, atomisation, droplet evaporation (interfacial heat and mass transfer), turbulent mixing and chemical reaction occur simultaneously in the presence of flow, mixture and phase inhomogeneities. The multi-scale nature and direct coupling between these various contributing processes, present a challenging fundamental problem which cannot be understood by extrapolation from homogeneous, inhomogeneous (gaseous) and even single droplet combustion studies.

Autoignition is a multi-physics phenomenon that occurs in wide-ranging engineering applications, such as diesel engines, gas turbines and jet-engine afterburners. In these applications, autoignition occurs in the presence of flow inhomogeneities and turbulence. Liquid fuel autoignition presents a case of chemically reacting flow where processes such as jet break-up, atomisation, droplet evaporation (interfacial heat and mass transfer), turbulent mixing and chemical reaction occur simultaneously in the presence of flow, mixture and phase inhomogeneities. The multi-scale nature and direct coupling between these various contributing processes, present a challenging fundamental problem which cannot be understood by extrapolation from homogeneous, inhomogeneous (gaseous) and even single droplet combustion studies.

The CEP Laboratory is equipped with a state-of-the-art experimental apparatus for a parametric study of the effect of flow inlet conditions on autoignition of polydispersed droplets of pure liquid fuels. A vertically mounted and optically accessible quartz reactor of circular cross-section receives upwards flowing air with temperatures up to 1150 K and velocities up to 40 m/s. Liquid fuel is injected continuously and axi-symmetrically from a water-cooled circular nozzle (placed concentrically at the reactor inlet) into this confined turbulent coflow of high temperature air at atmospheric pressures. Dynamic measurements of temperature with fine thermocouples and; optical non-intrusive measurements (with high-speed cameras) are performed to obtain quantitative data on autoignition delay time, location, frequency; fuel jet break-up, drop formation and evaporation.

Research application/scope:

- Improve design of combustors in engines and gas turbines for efficient fuel utilisation and reduction of harmful emissions by predicting and controlling autoignition.

- Measurements constitute a valuable data-set for validating and developing computational models of multiphase turbulent combustion and chemically reacting flows.

Selected publications:

- H. Moran, A. Gupta, V. Voulgaropoulos, C. N. Markides, 2018. Autoignition of a liquid n-heptane jet injected into a confined turbulent hot co-flow. 3rd South East European Conference on Sustainable Development of Energy, Water and Environment Systems. At: Novi Sad, Serbia. Link here.

- A. Gupta, C. N. Markides, 2017. Turbulent inhomogeneous autoignition of polydispersed n-heptane droplets: an experimental study. 2nd Thermal and Fluids Engineering Conference. At: Las Vegas, Nevada, USA. dx.doi.org/10.1615/TFEC2017.cbe.018106.

- A. Gupta, C. N. Markides, 2017. An experimental study of the autoignition of polydispersed liquid-fuel droplets in a confined high-temperature turbulent coflow. 8th European Combustion Meeting. At: Dubrovnik, Croatia. Link here.

- C. N. Markides, N. Chakraborty, 2013. Statistics of the scalar dissipation rate using direct numerical simulations and planar laser-induced fluorescence data. Chemical Engineering Science 90: 221. doi.org/10.1016/j.ces.2012.12.026.

Polymers, micro- and nano-additives, modified surfaces/interfaces

In this theme, we manipulate the physical, surface and interfacial properties of single and multiphase systems to control and/or enhance their flow characteristics and heat transfer properties, such as turbulence and mixing levels, flow regimes, nucleation site density, phase change rates. Specifically in the Drag Reduction Experiment and Diagnostic (DREAD) rig, pipe flow experiments are conducted to further understand the mechanism of drag reduction and the parameters that affect it. The effect of parameters such as polymer concentration, polymer type, molecular weight and aggregation time, on the level of drag reduction and on the degradation of the polymer in turbulent flow are studied. A novel mechanism that is able to explain the inhomogeneity of the polymer concentration profile across the pipe section when drag reduction is occurring has been proposed.

In this theme, we manipulate the physical, surface and interfacial properties of single and multiphase systems to control and/or enhance their flow characteristics and heat transfer properties, such as turbulence and mixing levels, flow regimes, nucleation site density, phase change rates. Specifically in the Drag Reduction Experiment and Diagnostic (DREAD) rig, pipe flow experiments are conducted to further understand the mechanism of drag reduction and the parameters that affect it. The effect of parameters such as polymer concentration, polymer type, molecular weight and aggregation time, on the level of drag reduction and on the degradation of the polymer in turbulent flow are studied. A novel mechanism that is able to explain the inhomogeneity of the polymer concentration profile across the pipe section when drag reduction is occurring has been proposed.

Selected publications:

- V. Voulgaropoulos, I. Zadrazil, N. Le Brun, A. Bismarck, C. N. Markides, 2019. On the link between experimentally‐measured turbulence quantities and polymer‐induced drag reduction in pipe flows. AIChE Journal 65: 16662. doi.org/10.1002/aic.16662.

- N. Le Brun, I. Zadrazil, L. Norman, A. Bismarck, C. N. Markides, 2016. On the drag reduction effect and shear stability of improved acrylamide copolymers for enhanced hydraulic fracturing. Chemical Engineering Science 146: 135. doi.org/10.1016/j.ces.2016.02.009.

- I. Zadrazil, C. N. Markides, 2014. A mechanism of polymer induced drag reduction in turbulent pipe flow. 10th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (HEFAT). At: Orlando, Florida, USA. hdl.handle.net/2263/44533.

- I. Zadrazil, A. Bismarck, C. N. Markides, 2012. Shear layers in the turbulent pipe flow of drag reducing polymer solutions. Chemical Engineering Science 72: 142. doi.org/10.1016/j.ces.2011.12.044.

Highlights

- Ibarra et al. published a new paper "Experimental investigations of upward-inclined stratified oil-water flows using simultaneous two-line planar laser-induced fluorescence and particle velocimetry" in the International Journal of Multiphase Flow in 2021. Access the article here.

- An et al. published a new open-access paper "Study of disturbance wave development in downwards annular flows with a moving frame-of-reference brightness-based laser-induced fluorescence method" in Experiments in Fluids in 2020. Access the article here.

- Voulgaropoulos et al. published a new paper "Transient freezing of water between two parallel plates: A combined experimental and modelling study" in the International Journal of Heat and Mass Transfer in 2020. Access the article here.

- Charogiannis et al. published a new paper "Spatiotemporally resolved heat transfer measurements in falling liquid-films by simultaneous application of planar laser-induced fluorescence (PLIF), particle tracking velocimetry (PTV) and infrared (IR) thermography" in Experimental Thermal and Fluid Science in 2019. Access the article here.

- Dr. Ajay Gupta presented results from this work at the European Combustion Meeting (April 18 – 21, 2017) in Dubrovnik, Croatia.

- On 13 March 2017, Professor Pietro De Palma from Politecnico di Bari visited the our group and gave the seminar "An advanced CFD tool for conjugate-heat-transfer problems in complex geometries".

- Professor Christos Markides presents his research on Interfacial Waves and Flow Velocity in Annular Flow at the Geoff Hewitt Celebration Conference on Multiphase Flow, July 2014.

- On September 24, 2013, Dr. Ajay Gupta presented this workat the Current Research in Combustion Research Forum, Loughborough, United Kingdom.