Radiography of Sub-sea Pipelines

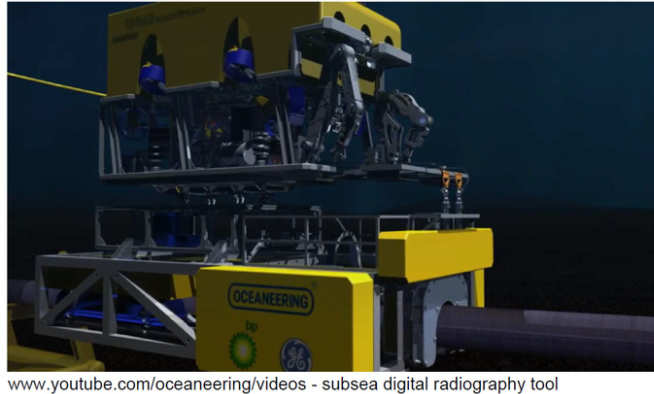

Accurate and reliable detection of subsea pipeline corrosion is required in order to verify the integrity of the pipeline. Often a pipeline can be inspected internally by pigging, however where this cannot be applied external examination must be used. Radiography holds a significant advantage over many other NDT methods in that it does not require surface preparation or insulation removal. Subsea radiography often exploits modern digital detectors, and thus has great potential to benefit from the advantages these offer. Identifying the most suitable imaging setups is crucial, both for cost effectiveness and reliable detection and sizing of defects.

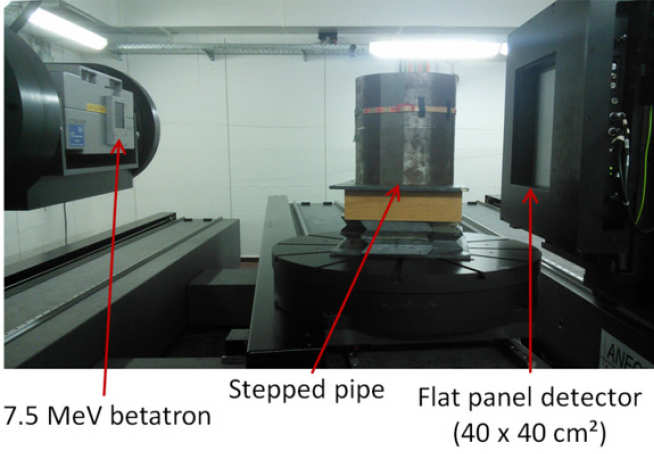

Standards for radiographic imaging of pipeline corrosion do not currently cover underwater conditions, and as water is highly scattering it can have a significant impact on radiographic image quality: thus it is vital to investigate inspection configurations with water. Subsea radiography is extremely costly, and extensive experimental data for research is difficult to obtain. Simulations are significantly more affordable and accessible than subsea experimental data. However, simulation models have not been validated as accurate for underwater imaging. Therefore in the first part of the project we aim to validate a radiographic simulation tool for use modelling underwater radiography. The model can then be used to investigate different radiographic setups.

The second part of this project deals with defect characterisation. Accurate measurement of defect dimensions in radiographs generally requires additional items such as a step wedge to be included in the exposure, placed on the pipe as close as possible to the region of interest. In a subsea environment, where the inspection is being controlled through a remotely operated vehicle, it is unlikely that inclusion of other objects such as a step wedge is possible. Therefore there is a need to develop methods of defect characterisation that do not require additional objects in the setup. In this part of the project a method of pipeline defect characterisation based on knowledge of the setup geometry and the use of images taken at different angles around the pipe is being developed.

Funding Sources and Sponsors

- EPSRC EP/I017704/1 (Centre for Doctoral Training in Non-Destructive Evaluation)

- Royal Commission for the Exhibition of 1851 (Industrial Fellowship)

- BP plc.

References

M. I. Haith, U. Ewert, S. Hohendorf, C. Bellon, A. Deresch, P. Huthwaite, M. J.S. Lowe and U. Zscherpel, “Modelling based Radiography for NDE of Subsea Pipelines”, in Review of Progress in Quantitative Nondestructive Evaluation, American Institute of Physics 1706, 110004 (2016).

U. Ewert, M. Tschaikner, S. Hohendorf, C. Bellon, M. I. Haith, P. Huthwaite and M. J. S. Lowe, “Corrosion monitoring with tangential radiography and limited view computed tomography”, in Review of Progress in Quantitative Nondestructive Evaluation, American Institute of Physics 1706, 110003 (2016).

Sponsor

BP