SHM Facilities

Structural Integrity and Health (SIHM) Monitoring Lab

SIHM Lab

The SIHM lab is located in room 139 City and Guilds Building (CAGB). The lab contains state of the art equipment for structural health monitoring (Ultrasonic Guided wave, Fibre Optic sensors).

Ultrasonic Guided Wave - UGW:

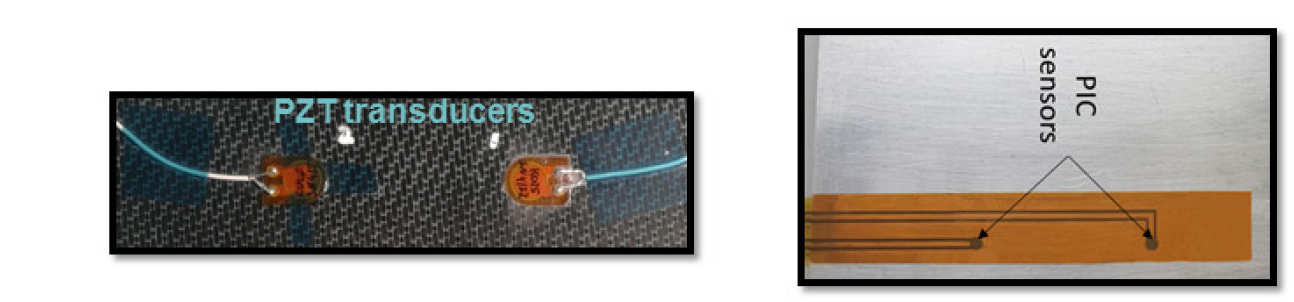

Piezo ceramic transducers are ideal as both sensors and actuators of UGW, since they require very little power, allow for multimode excitation, are very small and light. However, they are brittle and they require wiring and shielding.

Data Acquisition:

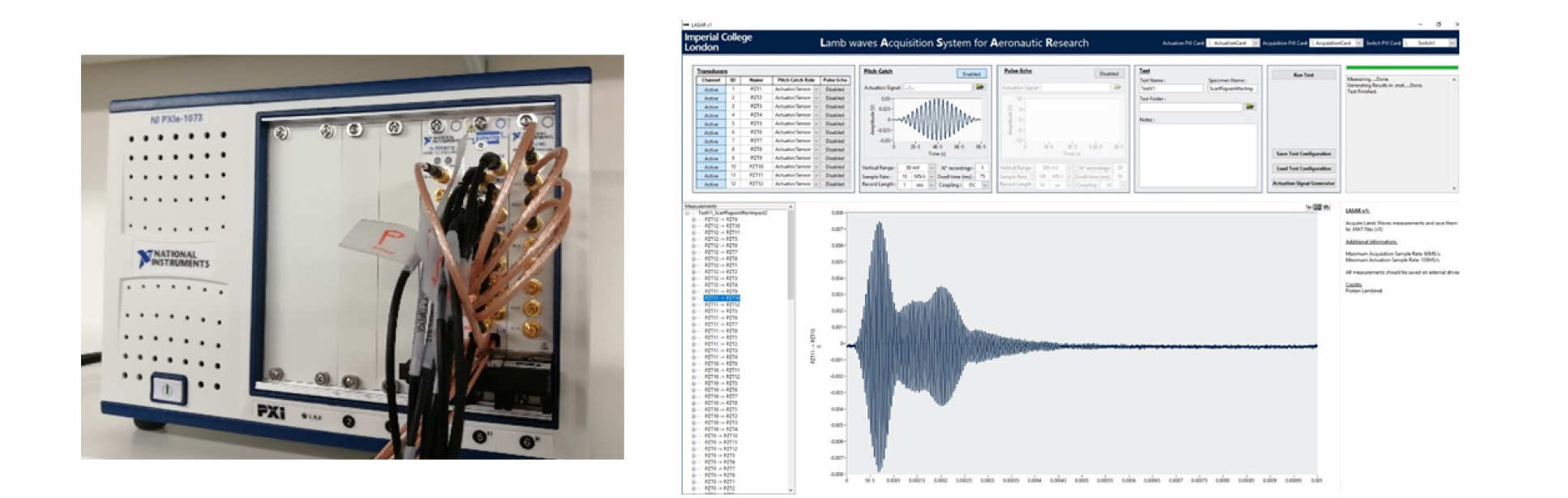

In addition to our developed data acquisition units for guided waves, our SHM lab also has several national instrument PXI3-1073 Chassis are available for data acquisition of PZT sensor network, each equipped with a PXI 5412 Waveform generator, a 8-Channel PXI 5105 Oscilloscope and a 12x8 RF coaxial matrix switch. External signal amplifiers are also available.

Our group has designed and developed an acquisition software which is optimized for our application, capable of handling large amount of data.

Hybrid PZT-FO system:

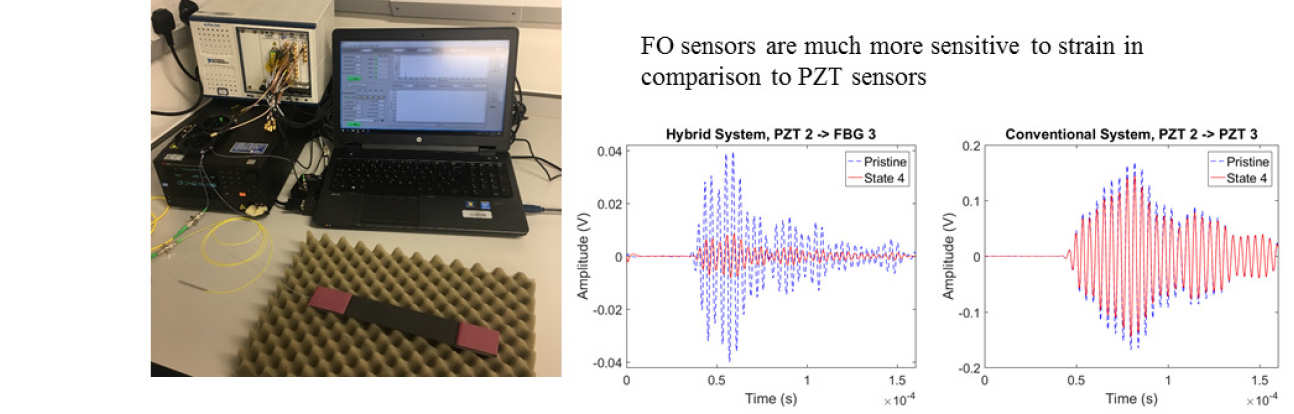

In a hybrid system the advantages of utilising PZTs as actuator is combined together with the advantages of the FO sensors which are high sensitivity to strain, low weight, temperature compensation, possibility of multiplexing and immunity from electromagnetic interference. The setup comprise of:

- Arbitrary Wave Generator (AWG) to excite the PZT actuator

- The tunable laser is used as a light source

- A light beam is divided into two paths through an optical circulator: one part enters the array of FBG sensors and the other part is combined with the light reflected from the FBG and measured using a photodetector.

- The intensity of the reflected light from the sensor is spectrally filtered and converted to voltage by photodetector.

As the strain on the FO sensor changes in time (due to the propagating Lamb wave), the reflected wavelength shifts up and down and causing a varying voltage signal in time domain.

Fibre Optic Sensors:

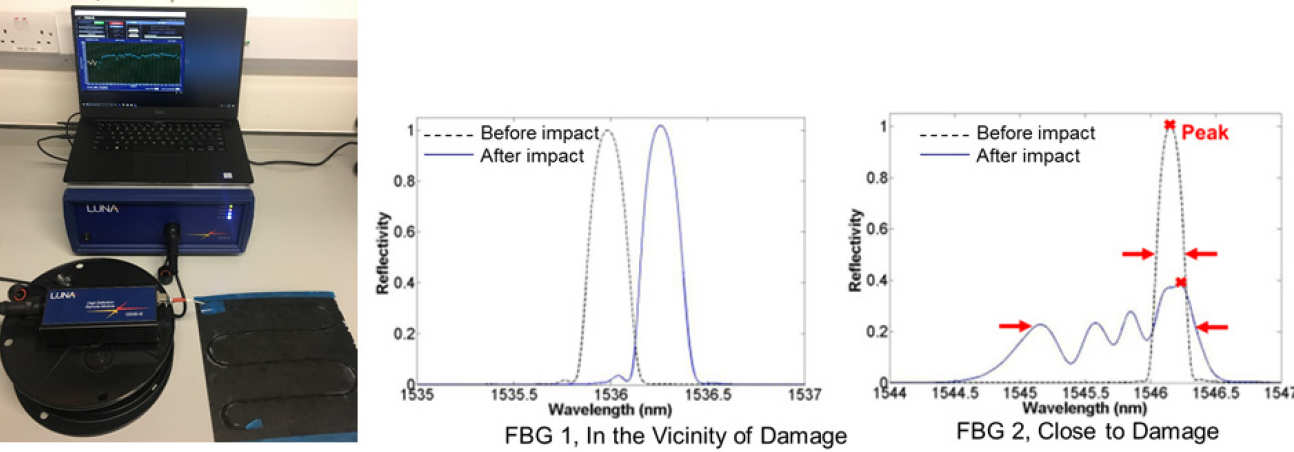

Strain monitoring with Fibre Optics (FO) can be achieved by either embedded FOs or surface mounted FOs (bonded or co-cured) each with their advantages and disadvantages. The FO are light, highly sensitive to strain and temperature, multiple Bragg Grating sensors can be engineered on a single fibre and they have immunity from electromagnetic interference. The can be used as point sensors with Bragg Gratings (Fibre Bragg Gratings or Draw Tower Gratings) or distributed fibre sensing (DFS with LUNA system):

- FBG or DTGs: monitoring changes in the spectrum of the reflected light;

- DFS: monitoring changes in the spectral shift of the Rayleigh scatter in the optical fibre using optical frequency domain reflectometry (OFDR).

Environmental chamber:

Thermal Vacuum Chamber J2235 is available for durability and environmental effect studies. The chamber is capable of temperature control from -70 ⁰C to 180 ⁰C, pressure control from 20kPa to 180kPa control, and humidity control. The inner chamber dimensions are 500mm diameter and 500mm depth which fit multiple coupons or complex structures. Four airtight cable access are available for connecting the data acquisition system to the specimens inside the chamber.