We provide mechanical testing of intervertebral body fusion devices and artificial discs to the following standards:

Test procedures

Test methods for intervertebral body fusion devices

This test method covers the static and dynamic fatigue testing of intervertebral body fusion device assemblies to provide a basis for the mechanical comparison of your device with past , present, and future devices.

Depending on the specifications of the device, this includes a combination of the following tests:

- Static and dynamic compression

- Static and dynamic compression shear

- Static and dynamic torsion

The test set-up is adaptable to lumbar, thoracic, and cervical devices. The device is positioned between two test blocks to simulate a motion segment; stainless steel test blocks for static loading and polyacetal test blocks for dynamic loading.

The test blocks are prepared to mate geometrically with the device and are designed based on CAD data provided by the client.

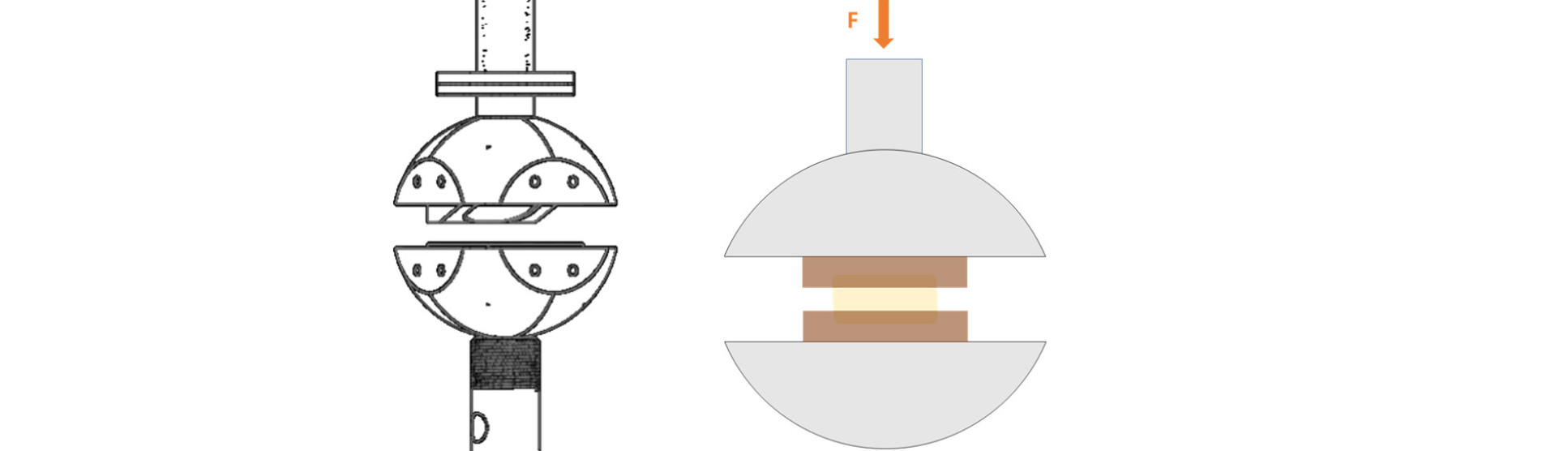

Test methods for measuring load induced subsidence of intervertebral body fusion devices

This test method covers the axial compression testing of intervertebral body fusion devices, allowing comparative evaluation of the load induced subsidence of your device with other past, present, and future devices.

Two different testing conditions are implemented under axial compression to determine both the device stiffness and the device’s propensity to subside.

- Stiffness - device inserted between two rigid metallic block and stiffness determined according to test methods of F2077

- Propensity to subside - device inserted between two polyurethane foam blocks to discern the stiffness of the system and polyurethane blocks, and determine the yield load

Both sets of test blocks are designed to mate geometrically with the device being tested, based off of the CAD data provided by the client.

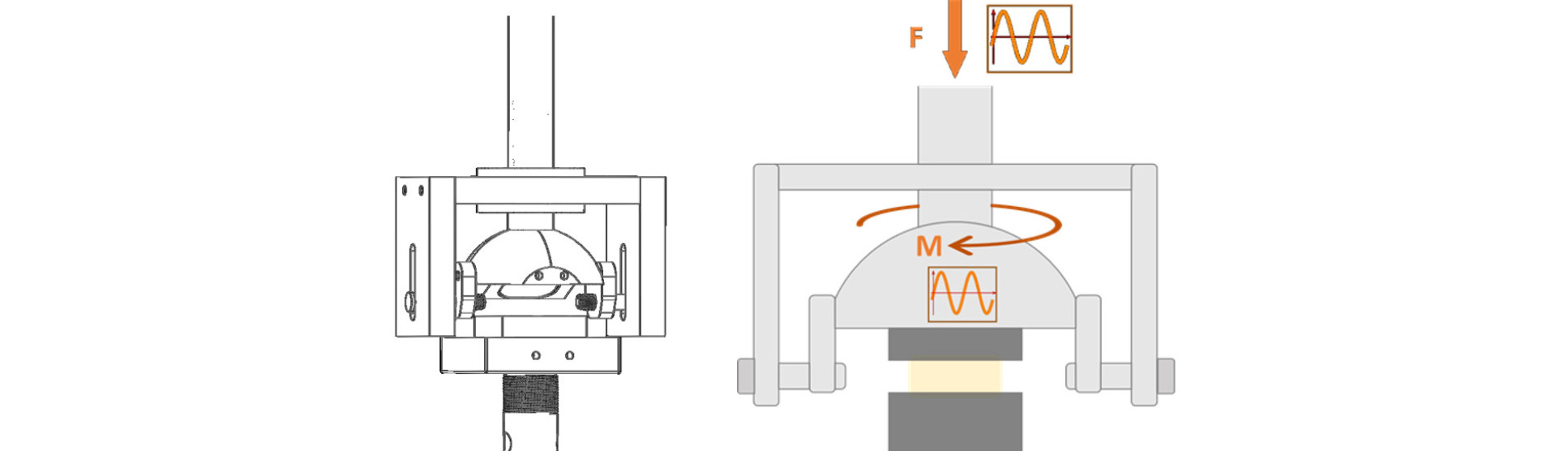

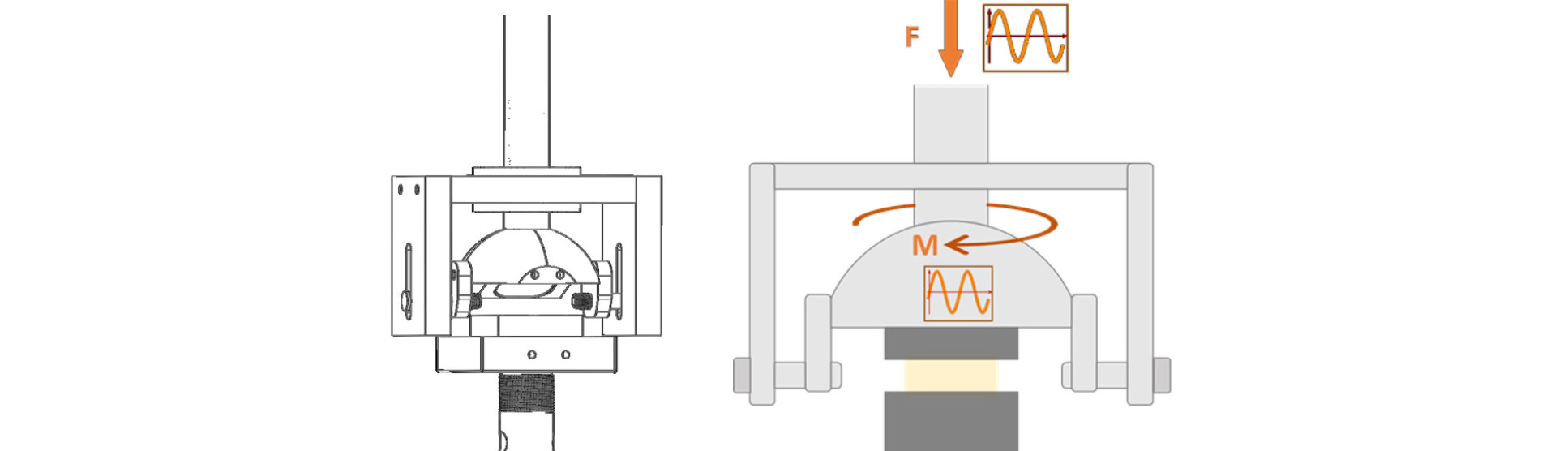

Test methods for the characterisation of spinal artificial discs

This test method covers the static and dynamic fatigue testing of non-biologic artificial intervertebral discs to provide a basis for the mechanical comparison of your implant with past , present, and future devices.

Depending on the specifications of the implant, this includes a combination of the following tests:

- Static and dynamic compression

- Static and dynamic compression shear

- Static and dynamic torsion

The test set-up is adaptable to lumbar, thoracic, and cervical implants. The device is positioned between two test blocks to simulate a motion segment; stainless steel test blocks for static loading and polyacetal test blocks for dynamic loading.

The test blocks are prepared to mate geometrically with the device and are designed based on CAD data provided by the client.

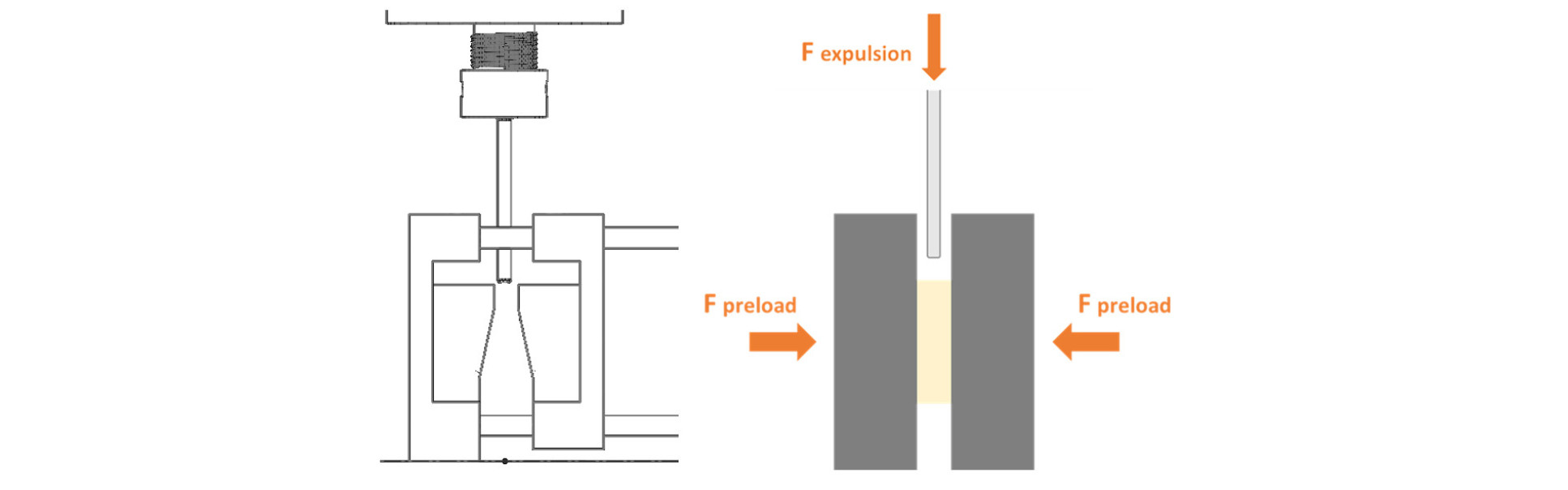

Test methods for the expulsion of spinal implants

This internal test method covers the static push-out of intervertebral body fusion devices or artificial discs to determine the mechanical resistance of these implants to expulsion. The test is based upon the ASTM draft standard F-04.25.02.02.

The device is positioned between two polyurethane blocks to simulate the motion segment and a constant preload is applied. The device is then subjected to an expulsion load in the posterior-anterior direction until 3mm displacement or failure occurs to establish the ultimate load.

This test can be conducted both with and without fixation methods, such as screws or expansion features, in order to characterise the additional mechanical resistance provided by fixation.

The polyurethane test blocks are prepared to mate geometrically with the device and are designed based on CAD data provided by the client.