Wearable sensors styled into t-shirts and face masks

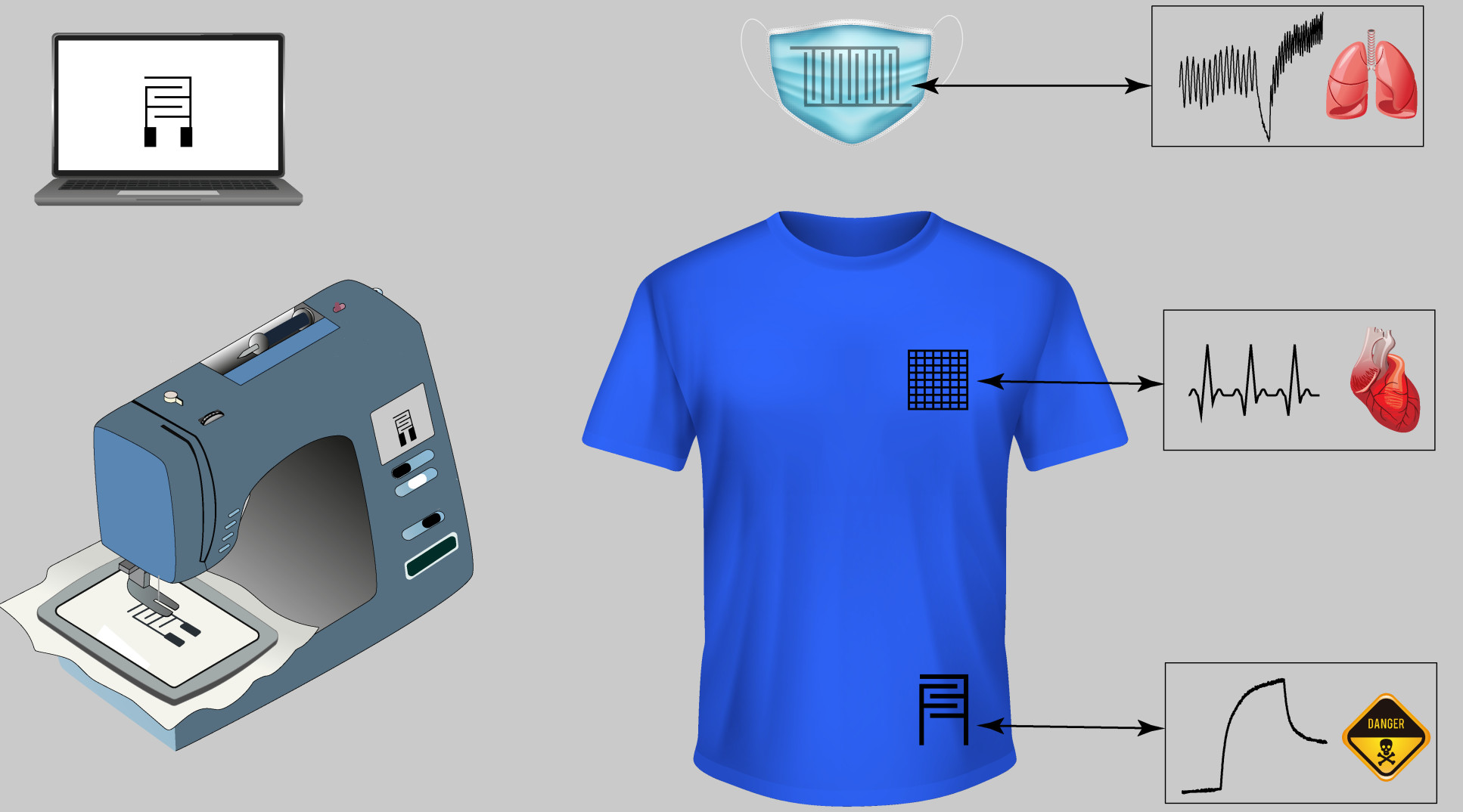

Imperial researchers have embedded new low-cost sensors that monitor breathing, heart rate, and ammonia into t-shirts and face masks.

Potential applications range from monitoring exercise, sleep, and stress to diagnosing and monitoring disease through breath and vital signs.

The flexible medium of clothing means our sensors have a wide range of applications. Fahad Alshabouna Department of Bioengineering

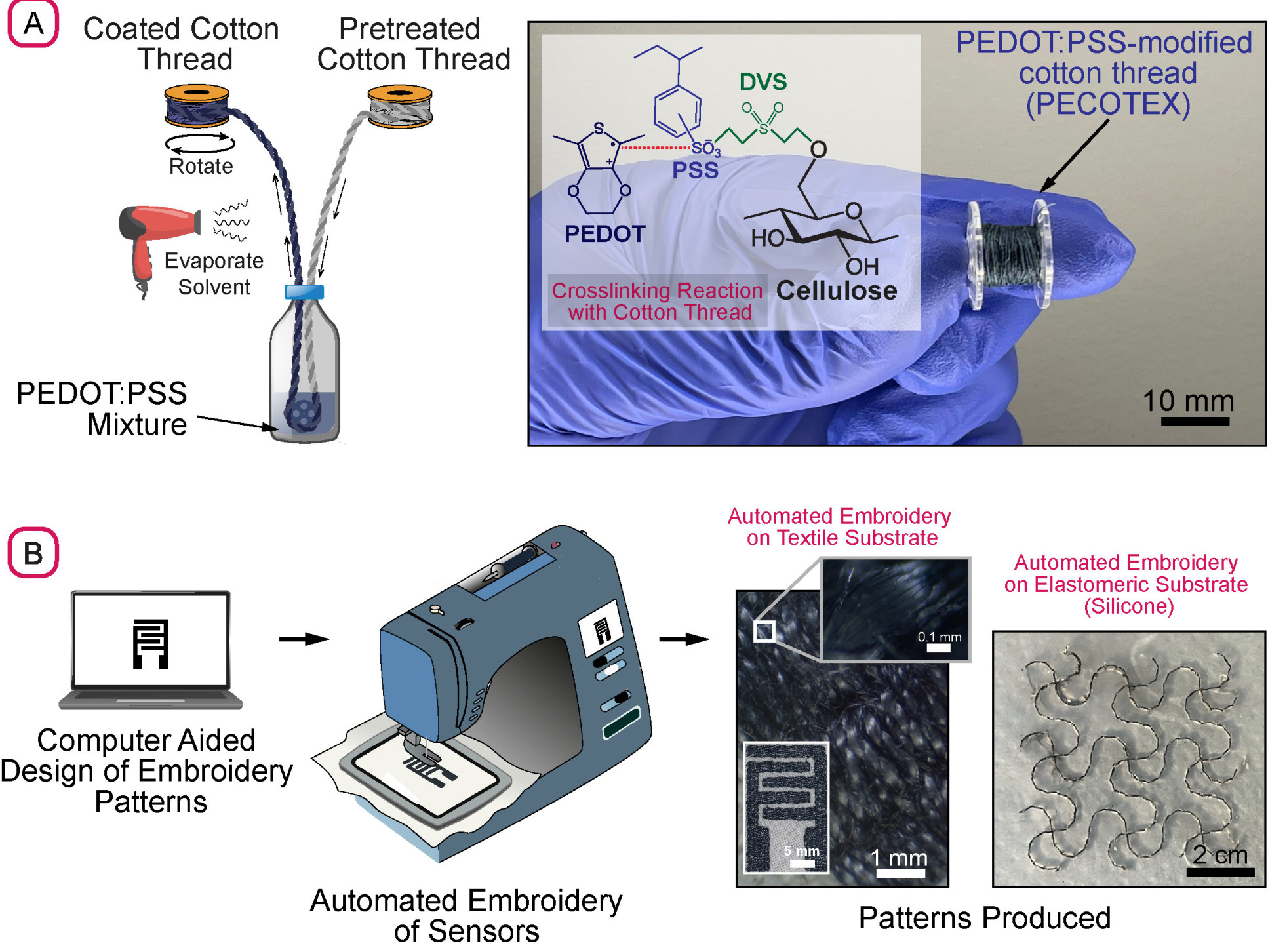

Spun from a new Imperial-developed cotton-based conductive thread called PECOTEX, the sensors cost little to manufacture. Just $0.15 produces a metre of thread to seamlessly integrate more than ten sensors into clothing, and PECOTEX is compatible with industry-standard computerised embroidery machines.

First author of the research Fahad Alshabouna, PhD candidate at Imperial’s Department of Bioengineering, said: "The flexible medium of clothing means our sensors have a wide range of applications. They’re also relatively easy to produce which means we could scale up manufacturing and usher in a new generation of wearables in clothing."

The researchers embroidered the sensors into a face mask to monitor breathing, a t-shirt to monitor heart activity, and textiles to monitor gases like ammonia, a component of the breath that can be used to detect liver and kidney function. The ammonia sensors were developed to test whether gas sensors could also be manufactured using embroidery.

Fahad added: "We demonstrated applications in monitoring cardiac activity and breathing, and sensing gases. Future potential applications include diagnosing and monitoring disease and treatment, monitoring the body during exercise, sleep, and stress, and use in batteries, heaters, and anti-static clothing."

The research is published in Materials Today.

Seamless sensors

Wearable sensors, like those on smartwatches, let us continuously monitor our health and wellbeing non-invasively. Until now, however, there has been a lack of suitable conductive threads, which explains why wearable sensors seamlessly integrated into clothing aren’t yet widely available.

Enter PECOTEX. Developed and spun into sensors by Imperial researchers, the material is machine washable, and is less breakable and more electrically conductive than commercially available silver-based conductive threads, meaning more layers can be added to create complex types of sensor.

"PECOTEX is high-performing, strong, and adaptable to different needs... Our research opens up exciting possibilities for wearable sensors in everyday clothing." Dr Firat Güder Department of Bioengineering

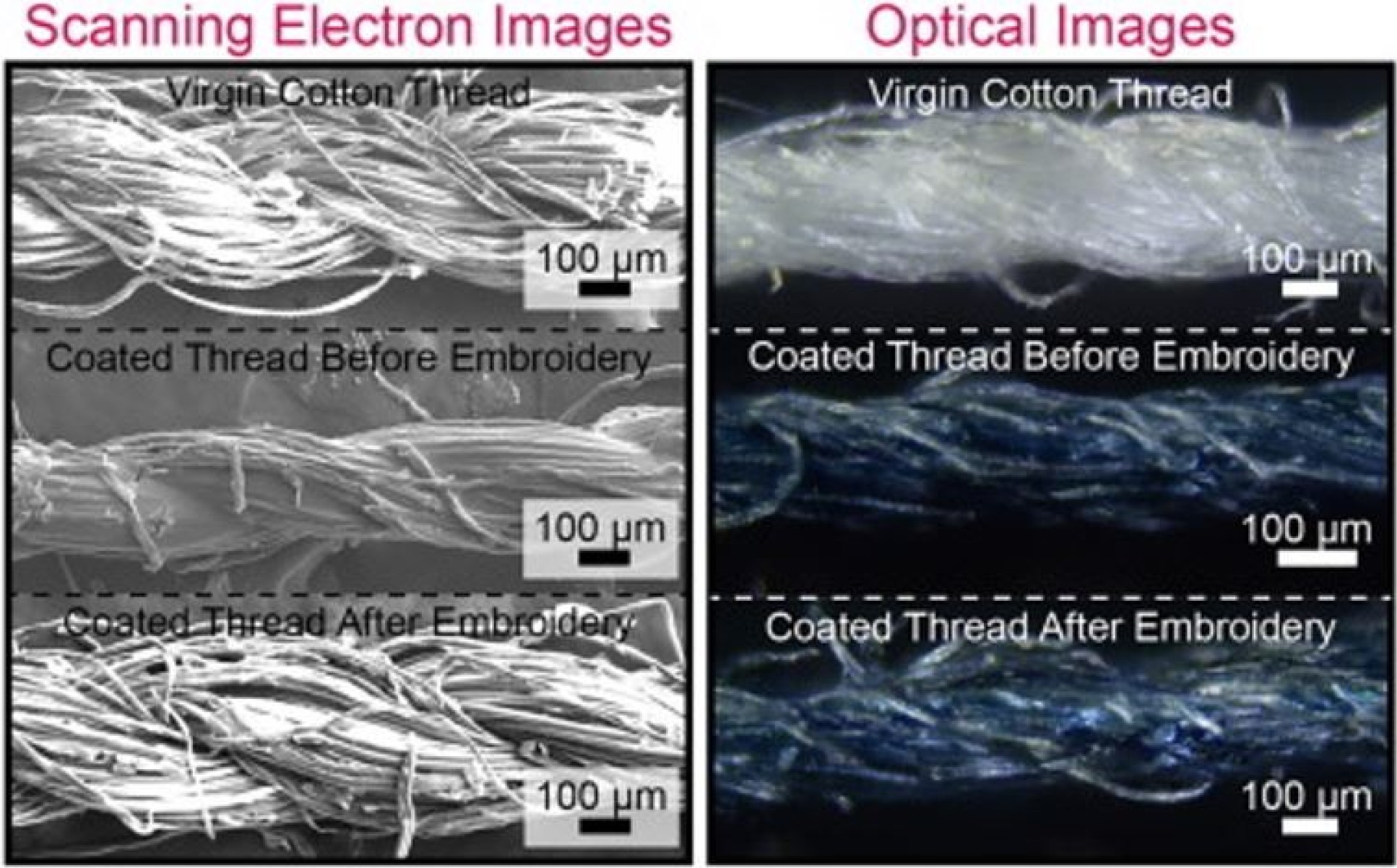

The researchers tested the sensors against commercially available silver-based conductive threads during and after they were embroidered into clothing.

During embroidery, PECOTEX was more reliable and less likely to break, allowing for more layers to be embroidered on top of each other.

After embroidery, PECOTEX demonstrated lower electrical resistance than the silver-based threads, meaning they performed better at conducting electricity.

Lead author Dr Firat Güder, also of the Department of Bioengineering, said: "PECOTEX is high-performing, strong, and adaptable to different needs. It’s readily scalable, meaning we can produce large volumes inexpensively using both domestic and industrial computerised embroidery machines.

"Our research opens up exciting possibilities for wearable sensors in everyday clothing. By monitoring breathing, heart rate, and gases, they can already be seamlessly integrated, and might even be able to help diagnose and monitor treatments of disease in the future."

The embroidered sensors retained the intrinsic properties of the fabric such as wearability, breathability and feel-on-the-skin. They are also machine washable at up to 30°C.

Next, the researchers will explore new application areas like energy storage, energy harvesting and biochemical sensing for personalised medicine, as well as finding partners for commercialisation.

This study was funded by the Saudi Ministry of Education, Engineering and Physical Sciences Research Council (EPSRC, part of the UKRI), Cytiva, Imperial’s Department of Bioengineering, Bill and Melinda Gates Foundation, and the US Army.

"PEDOT:PSS-modified cotton conductive thread for mass manufacturing of textile-based electrical wearable sensors by computerized embroidery" by Alshabouna et al., published 6 September 2022 in Materials Today.

Images and video credits: Güder Research Group.

Article supporters

Article text (excluding photos or graphics) © Imperial College London.

Photos and graphics subject to third party copyright used with permission or © Imperial College London.

Reporter

Caroline Brogan

Communications Division