Maxximus: MAAXIMUS (More Affordable Aircraft through eXtended, Integrated and Mature nUmerical Sizing) was aimed at achieving the fast development and right-first time validation of a highly-optimised composite fuselage through a consorted action between virtual structure development and composite technology.

The Consortium that was made up of 54 partners, gathered the key players with a budget is 67M€ (EUFP7 work grant number 213371 and led by AIRBUS).

Our team was involved in the highly-Optimised Composite Fuselage: Enable a high-production rate: 50% reduction of the assembly time of fuselage section Reduce the manufacturing and assembly recurring costs by 10%; Reducing weight by 10%, compared to (F7X, A320 and TANGO fuselage). Faster Development: Reduce by 20% from preliminary design up to full-scale test.

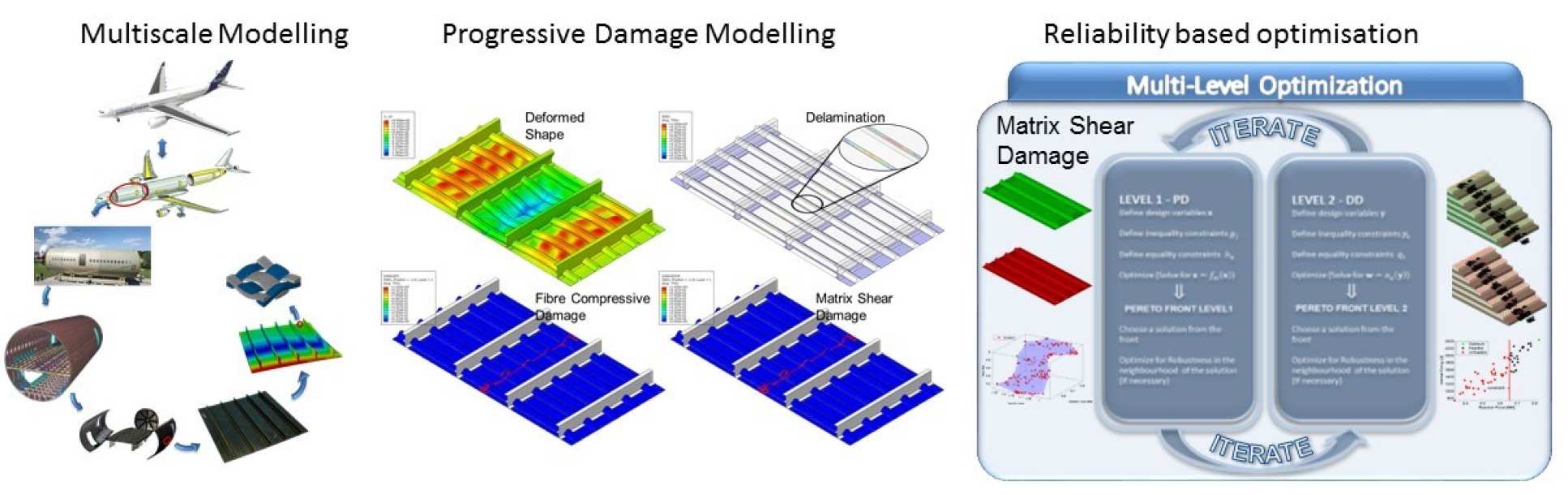

As part of the project, we developed a multiscale modelling for complex composite architecture including woven textile; progressive damage modelling and residual strength evaluation of complex composite stiffened panels and multilevel reliability based optimisation.