Name: Yun-Hao Hsieh

Supervisors: Prof Bill Lee and Prof T.D. Waite (UNSW, Sydney, Australia)

Sponsor: The UNSW Tyree Scholarship

Many advanced reprocessing technologies have been designed and developed to meet the future nuclear waste policies and further separate waste. One of the most promising advanced reprocessing methods, EURO-GANEX (Group Actinides Extraction), is nowadays being developed and aim to further separate both major (U, Pu) and minor (Np, Am, and Cm) actinides together from fission products. In that context, new advanced immobilization matrices capable of accommodating such modified waste streams have to be investigated1,2.

Synroc and borosilicate glass are potential wasteforms that have proven themselves to be efficient to immobilize high-level nuclear wastes (HLW)3. In this project, a new composition of Synroc, “Synroc-Z”, is designed and characterized. The primary modification is to reduce the amount of zirconolite phase, which acts as the main host for actinides.

Synroc-Z has been prepared via hot uniaxial pressing (HUP) and optimized the process conditions to obtain dense samples. A well-known borosilicate glass, R7T7, was melt to compare with HUPed Synroc-Z. In both wasteforms their durability via the MCC-1 test at 90oC and microstructure after corrosion was tested.

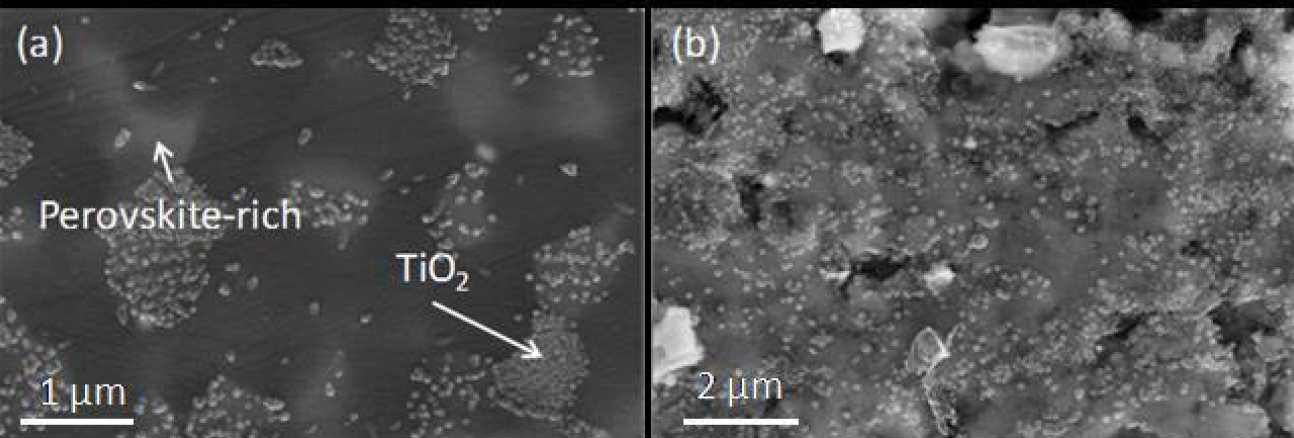

The mass loss before and after leaching test for Synroc-Z was negligible (< 0.02%) while the R7T7 glass was relatively larger (>0.35%). Nano TiO2 particles (~50 nm) were formed on the perovskite-rich surface. The thickness of TiO2 skin was determined via AFM which was ~60 nm. The leached sample which were polished to 1 um can be clearly observed that TiO2 particles were assembled on the brighter contrast area while the TiO2 particles were dispersed on the rougher (15 um polishing) Synroc-Z surface but dense on the edge of holes. The leached R7T7 glass formed Al, Zn and Si rich layer on the surface. The ratio of Al, Zn and Si of layer on the surface is ~1: 2: 4 while the composition of unleached R7T7 glass is ~2: 1: 18.

Figure 1. SEM images of 20 wt.% waste loading HUPed Synroc-Z samples with (a) 1 um and (b) 15 um polishing finish. The TiO2 particles compact on perovskite-rich regions. Samples with 15 um polished shows dispersed TiO2 skin but dense in some edges of holes.

References:

1. Advanced Separation Techniques for Nuclear Fuel Reprocessing and Radioactive Waste Treatment K. L. Nash and G. J. Lumetta, . Elsevier Science, (2011).

2. Development of a New Flowsheet for Co-Separating the Transuranic Actinides: The “EURO-GANEX” Process. M. Carrott, K. Bell, J. Brown, A. Geist, C. Gregson, X. Hères, C. Maher, R. Malmbeck, C. Mason, G. Modolo, U. Müllich, M. Sarsfield, A. Wilden, R. Taylor. Solvent Extraction and Ion Exchange, 32[5], p: 447-67, 2014.

3. Radioactive waste forms for the future. W. Lutze and R. C. Ewing. North-Holland, 1988.