Impact of Fast Firing on Phase Evolution in White-ware Ceramics

Name: Wirat Lerdprom

Supervisor: Prof Bill Lee

Sponsor: Cementhai Ceramics Co., Ltd, Thailand

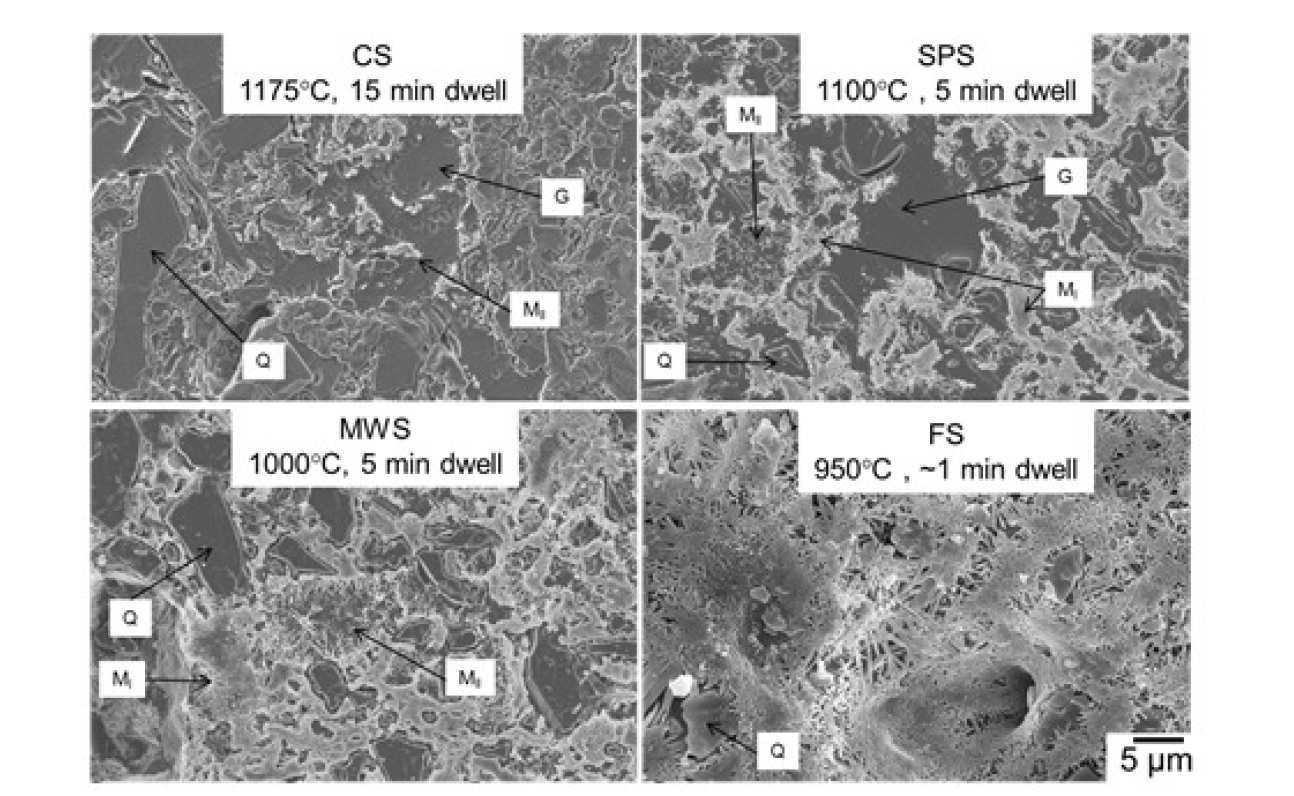

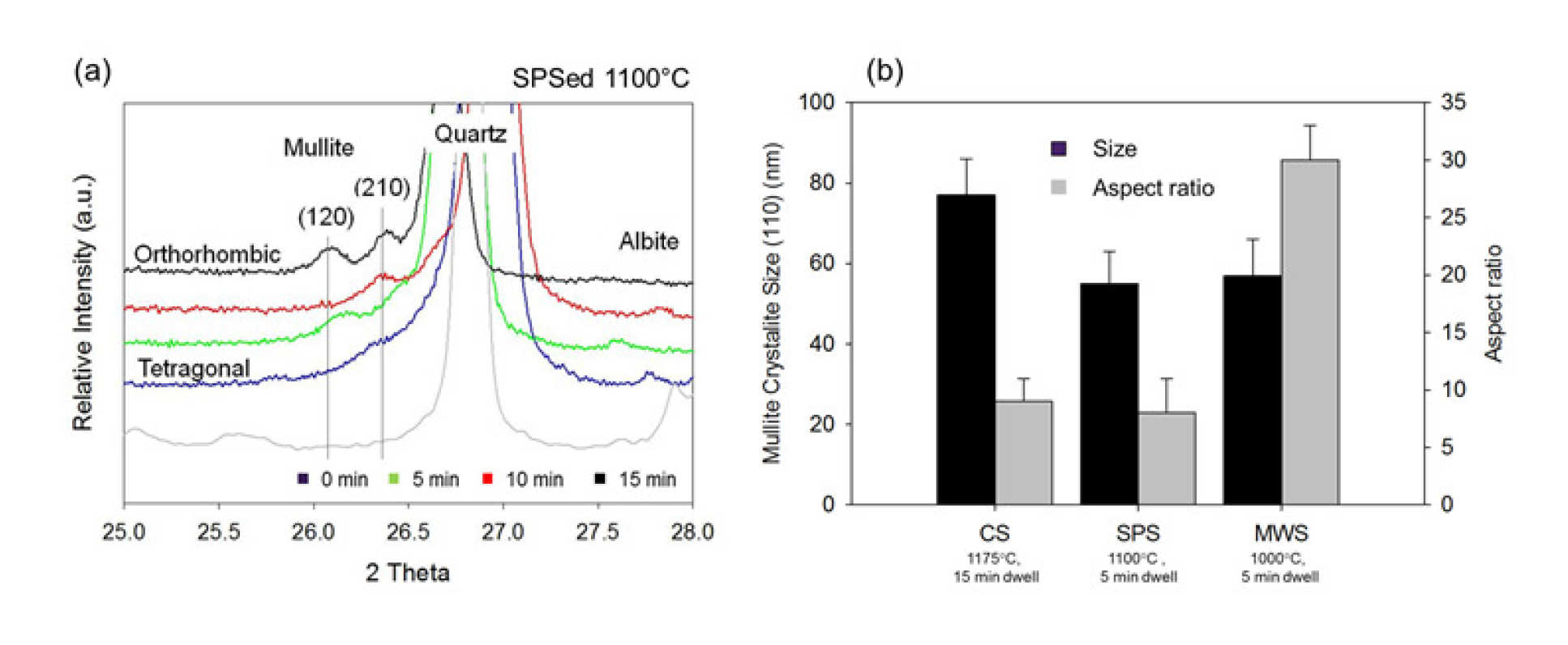

Porcelains are clay based materials, used extensively in household, scientific and engineering applications, which are produced via viscous flow sintering. The sintering process of porcelains is not only to densify the green body, but also to induce mineralogical phase changes. Densification and phase evolution are influenced by sintering conditions i.e. heating rate, dwell time, atmosphere, and temperature. New advanced sintering processes have been introduced aiming to improve product quality and energy usage efficiency such as conventional fast firing (CS), spark plasma sintering (SPS), flash sintering (FS) and microwave sintering (MWS), each of which has different process parameters. The aims of this work are to investigate microstructural and physicomechanical property changes (apparent bulk density, water absorption, Vickers hardness, and fracture toughness) in a porcelain body sintered using the 4 techniques and consider energy, financial and other aspects to determine which is most likely to find industrial application. The study involves investigation of mullitization, glass formation, and quartz dissolution from the different sintering techniques using X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy-dispersive spectroscopy (EDS). Finally, the ultimate goal of this work is to develop understanding of process parameters i.e. heating rate, pressure, atmosphere, electric field, and microwave radiation on mineralogical composition and densification in porcelains.

Figure 1. SEM-SE images of conventional sintered (CS), spark plasma sintering (SPS), microwave sintering (MWS), and flash sintered (FS) porcelain samples; showing etched samples using 20% HF (Ml=primary mullite, Mll=secondary mullite, G=glass, and Q =Quartz).

Figure 2. (a) XRD patterns of the SPSed samples showing different mullite crystal structure as a function of dwell times, (b) mullite crystallite size and aspect ratio of the porcelains sintered using different techniques.