Name: Tommaso Giovannini

Supervisor: Dr Finn Giuliani and Dr Daniel Balint.

Sponsor: SECO Tools

Machining operations are an integral part of manufacturing chains for numerous different industries. The cutting tools which perform these machining operations are subject to extremely harsh operational environments due to the high thermal and mechanical loads they are subjected to. Cutting tools are composed of a bulk substrate material, usually a cemented carbide, which is covered by a thin (~10 μm) ceramic based coating used to improve both the toughness and the wear resistance of the tool.

Improving the mechanical response of these ceramic coatings is of crucial importance to improve overall cutting tool performance. These improvements depend of a thorough understanding of the microstructural mechanisms which govern their deformation. These include the dependence of the coatings mechanical properties on parameters such as temperature, coating thickness and grain structure as well as the quality of adhesion between the coating and the substrate and in between layers, in multilayer coatings. One aspect which is particularly relevant, and has received little attention, is understanding the effect that these properties have on the plastic deformation behaviour of the coatings. Through the use of experimental work and microstructural modelling techniques the project aims to obtain a thorough understanding of these mechanisms and how they affect overall coating response. Having obtained this understanding the aim is then to propose coating design alterations aimed at improving overall coating performance.

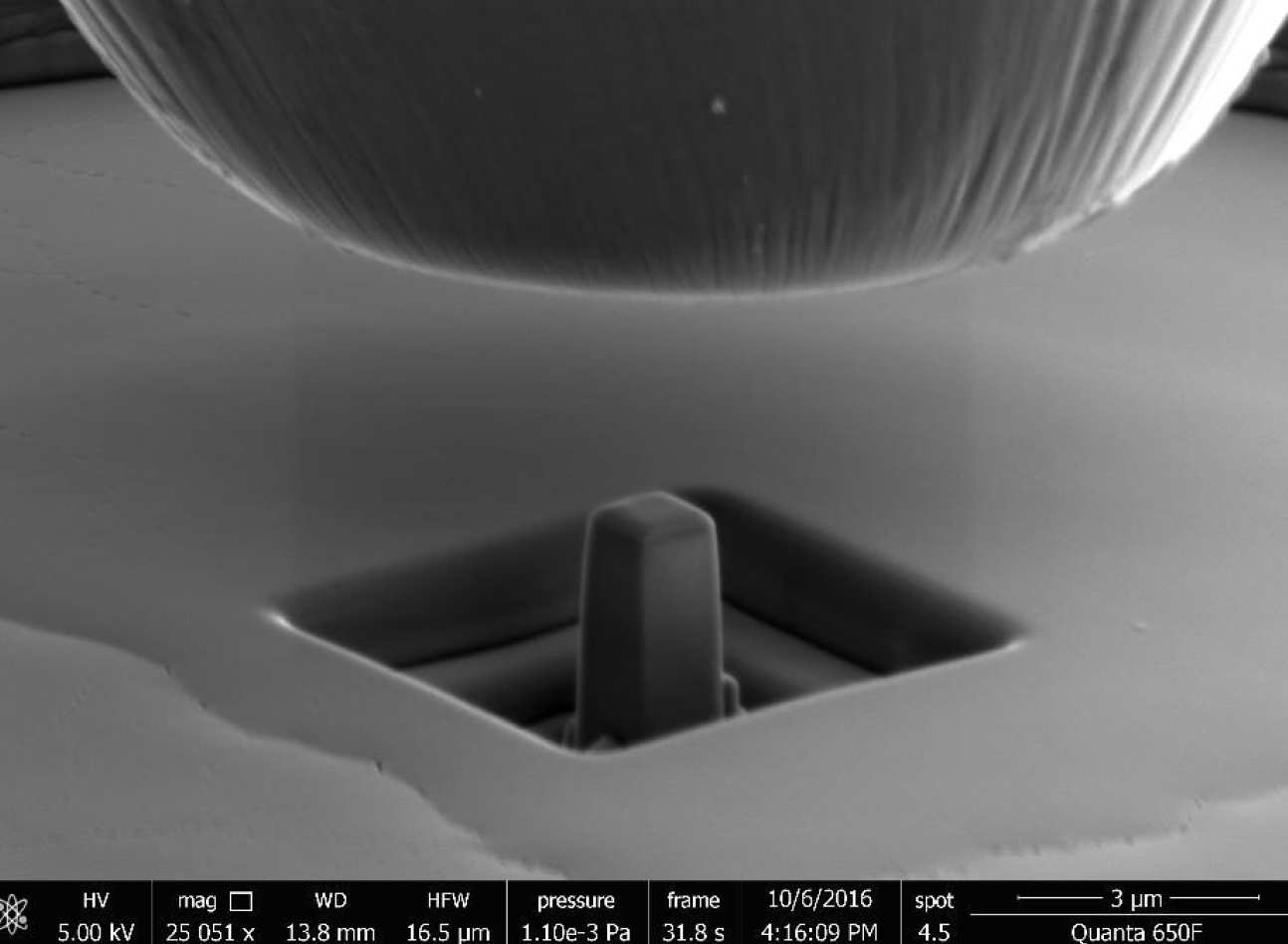

Figure 1. Micropillar compression experiment performed on a single grain in a highly textured Al2O3 coating.