PDRA: Oriol Gavalda Diaz

Supervisors: Finn Giuliani, Eduardo Saiz, Katharina Marquardt and Luc Vandeperre

The need to increase the cycle efficiency and reduce NOx emissions from aero-engines has promoted the development of Silicon Carbide (SiC) based Ceramic Matrix Composites (CMCs) which have entered in service in aircraft turbine engines as replacements for some Ni-based superalloys. The main tendency of material choice is converging to CMCs constituted by SiC fibres coated with a thin (0.1-1 µm) BN interphase within a SiC matrix (SiC/BN/SiC), resulting in an optimised tough ceramic composite. However, unlike the generic tendencies found for metallic materials, environmental effects seem to not follow a clear tendency as hottest temperatures do not necessarily result in more severe degradation. This is due to the complex degradation thermodynamics occurring at the interface of the SiC-BN system such as volatilisation of B species, borosilicate glass formation or formation of self-healing oxide products.

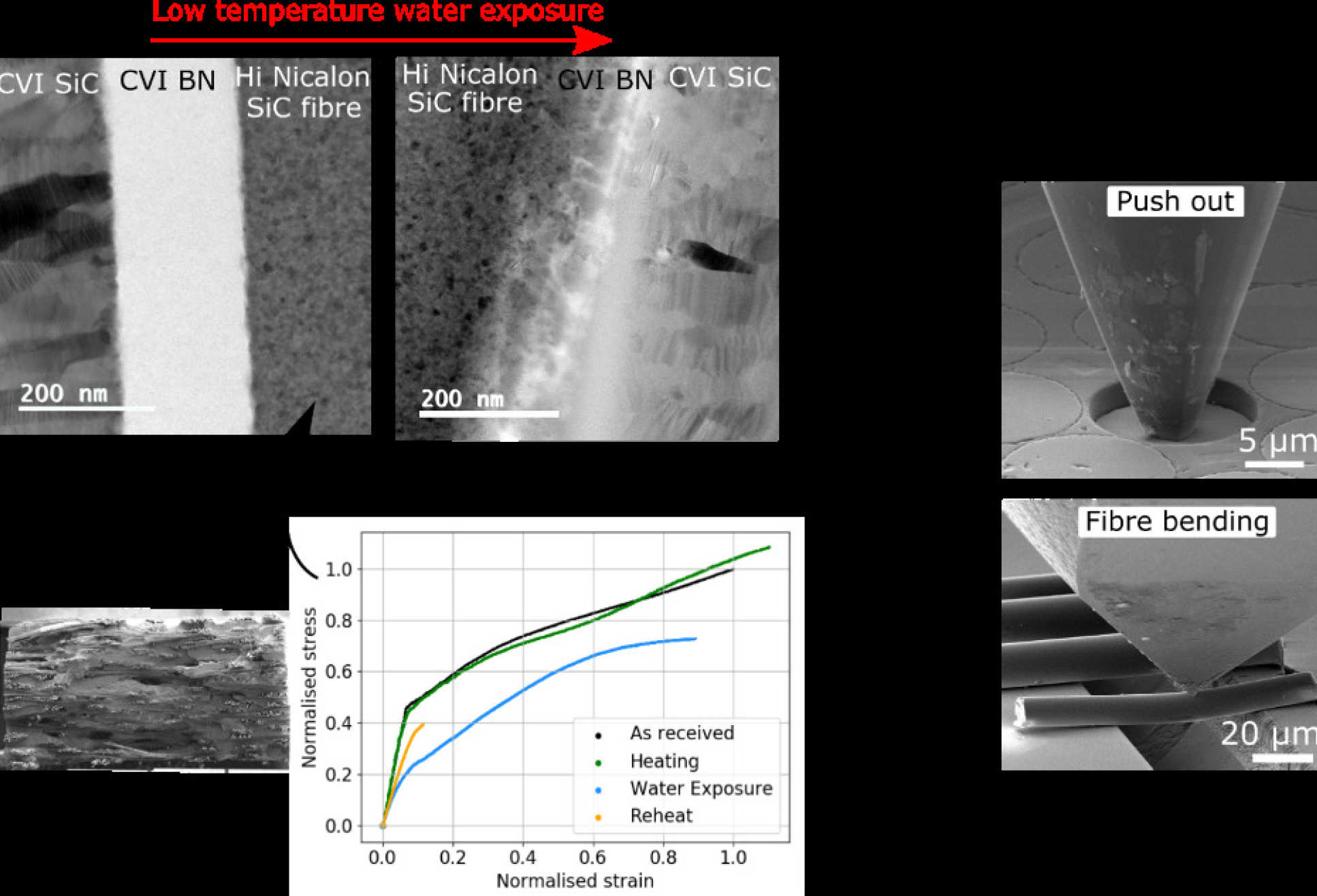

An important aim of this projects consists in understanding how the interfacial and fibre properties in SiC/BN/SiC are affected by different aero-engine inspired degradation cycles by exploring the interfacial properties via push-out tests and the fibre properties via three point bending of single fibres (see Figure 1). Further TEM-based characterization techniques are done in order to link the change in properties to the changes in chemistry and microstructure.