Current Projects

- An Advanced Modelling Approach for Investigating the Micromechanisms of Failure of Flexible Composite Pipes under Compression

- Biomimetic Tribology: Exploiting Natural Lubrication Mechanisms for Mechanical Systems

- Controlling Friction Through Molecular Engineering

- Fuel Spray Formation for Internal Combustion Engines

- Immersion Cooling of Lithium-Ion Batteries with Dielectric Fluids

- Lubricant Flow Inside Engines

- Machine-Learning Pattern Recognition Prototype for Liquid Foams

- Optimized EV Battery Charging and Discharging Profiles

- Polymeric Additives in Lubricants for Electric Vehicle Powertrains

- Tribofilm Properties of ZDDP-Containing Oils

- Tribology of Calcium Complex Greases

- Understanding Viscosity Modifier Additive Performance

Researcher: Benjamin Collard

Supervisor: Prof. Daniele Dini, Dr. Finn Giuliani (Materials)

Sponsor: EPSRC and Shell (iCASE)

Summary

The research programme will employ both semi-analytical models and advanced numerical techniques to develop predictive tools for the onset of instabilities responsible for the two types of observed microbuckling mechanisms in flexible composite pipes. Effect of different fluids and environmental conditions to which these pipes are exposed will also be investigated. The research carried out will be built on the experimental programme. Understanding of the micro-mechanisms of compressive failure in fibre composite polymer systems will promote more widespread use of fibre composite pipe in existing applications and provide options for harsher environments. This will allow more effective exploitation of hydrocarbon reserves.

Researcher: Murali Manoj

Supervisor: Dr Marc Masen, Dr Philippa Cann

Sponsor: NERC, Shell (Science and Solutions for a Changing Planet DTP)

Summary

The replacement of oil-based lubricants with biodegradable water-based lubricants has been a long-standing unfulfilled ambition. The physical instabilities and poor wear performance associated with water-based lubricants has led to minimal adoption within mechanical systems. However, many water-based lubrication systems exist within nature that are capable of providing extremely low friction and minimal wear.

This project aims to explore these natural lubrication mechanisms with the intention of exploiting their behaviour for application within mechanical systems. This will lead to the development of a biolubricant that is capable of providing suitable friction and wear characteristics for a multitude of applications. The biolubricant will be tuned to be compatible with materials that are likely to be adopted into many of the systems around us in the future. This allows for application of the lubricant within novel systems previously unexplored that may come to the forefront in the near future. Nature exhibits countless complex lubrication mechanisms and biological methods to achieve targeted lubrication. Hence, the focus is towards creating a biolubricant which is capable of local activation at a contact, thereby providing a local high viscosity zone with a bulk low viscosity and reducing energy losses due to churning or fluid shear. Some of the lubricant additive possibilities to be explored are proteins, cationic surfactant micelles and polymer-colloids amongst others.

Researcher: Dr James Ewen

Sponsor: Royal Academy of Engineering

Summary

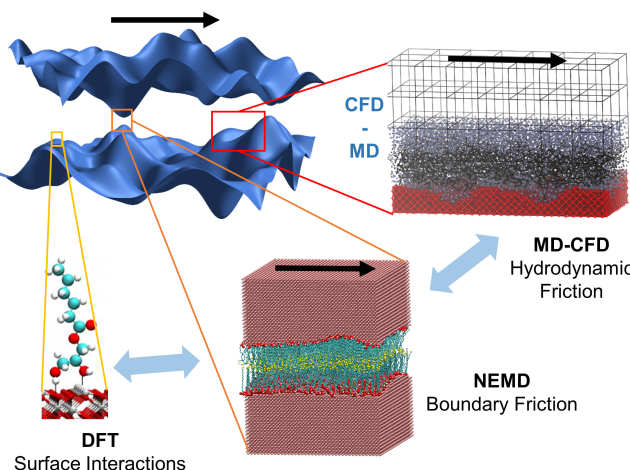

Lubricants help engines and other components run more efficiently by reducing friction between moving parts. This enables vehicles to use less fuel and produce fewer emissions. Improved lubricants could reduce the energy consumption and pollution from the transportation sector by up to a quarter.

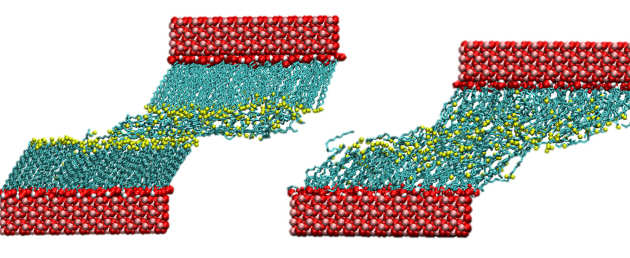

Through a combination of molecular science and engineering, Dr Ewen is developing methods to design new lubricants using computational approaches. The flexible tools he develops will also be used to optimise fluids required for the moving parts in electric vehicles. Dr Ewen will collaborate closely with researchers at Shell (via the University Technology Centre for Fuels and Lubricants) and Afton Chemical as well, as university researchers across Europe.

Shell technical stakeholder(s): Dr Roger Cracknell

Supervisor(s): Prof. Pavlos Aleiferis

PhD Student: Stavros Bontitsopoulos

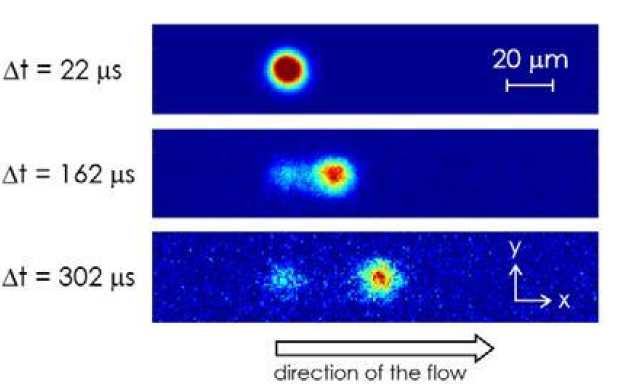

Overview & Objectives: The structure and evaporation of fuel sprays in Direct-Injection Spark-Ignition (DISI) engines has a profound impact on combustion efficiency and emissions. If the spray atomisation and air mixing process leads to pockets of rich fuel/air mixture, the effect can be increased particulate emissions and lower engine efficiency. In a fully warmed-up engine, the presence of light ends in gasoline can assist with spray breakup via flash boiling.

In this PhD project, the main focus is on spray breakup at cold conditions where the flash boiling mechanism does not typically apply and the penetration length of the fuel spray can be longer. Nowadays there is much more focus on emissions using Real World Driving, hence it is important to understand the effect of cold conditions on the structure of the fuel spray and the potential impact on emissions and performance of DISI engines.

The project uses advanced experimental techniques with emphasis on optical diagnostics to explain the behaviour of cold fuel spray formation and atomisation in the controlled environment of a constant volume injection chamber where thermodynamics conditions relevant to modern DISI engines will be reproduced. The potential impact of various factors such as in-nozzle cavitation and additives on spray formation under such conditions are also going to be explored.

Start Date: October 2018

Shell technical stakeholder(s): Dr Michael Parkes

Supervisor(s): Dr Billy Wu

PhD Student: Charlotte Rowe

Overview & Objectives: This PhD project will investigate the operational mechanisms around immersion cooling of lithium-ion batteries (LIBs) using dielectric fluids. LIBs are a key enabling technology for consumer electronics, electric vehicles (EVs) and for the integration of zeroemission renewable technologies such as wind and solar. Whilst their commercial adoption continues at pace, their cost, performance and lifetime still needs to be improved to be widely economically viable. Increases in the cost when translating from a single cell to a battery pack are due to the additional integration of components such as battery management systems and thermal management systems (TMS), with the thermal management system current contributing to ca. 20% of the total pack cost. With the battery performance and lifetime being highly thermally coupled, the effective design of a TMS is critical for achieving long term performance targets. In terms of power density, the 2035 target is 12 kW/kg which is still a long way away from the current performance of 3 kW/kg with a lifetime of ca. 15 years compared to current values of ca. 8 years. To compound this, future TMSs must also be able to operate over a temperature range of -40-80 degC which means alternative cooling media to water must be explored.

Currently, there are a range of TMSs being commercially exploited. The simplest approach is the use of natural convection to reject heat generated from the operation of LIBs. This is an approach taken by the Nissan Leaf, and whilst this is lowcost, the limited specific heat capacity (~1 kJ/kg.K) and convective heat transfer coefficient (~1-10 W/m2K) of the natural convection of air means that batteries can experience accelerated degradation due to higher temperature operation and also limited power capabilities due to thermal limits being reached. Tesla battery packs on the otherhand use a copper tube which is arranged in a serpentine pattern around the individual cylindrical cells of its pack to pass water to remove the heat. The advantage here is that water has a much higher specific heat capacity (~1,000 kJ/kgK). The disadvantage of this approach is the additional weight of the heat pipes, the suboptimum thermal contact between the cells and the cooling media as well as uneven cooling between cells which can lead to accelerated degradation.

Research efforts have investigated various alternative cooling methods such as the use of phase change materials (PCM) like Paraffin. Whilst these PCMs do have very good specific heat capacitances (~2,000 kJ/kgK) due to the additional latent heat energy (~200 kJ/kgK) associated with the phase change from solid-to-liquid, their performance once in the melted state is not ideal since PCMs do not dissipate heat well in part due to the stagnant nature of the material when solid preventing circulation of the cooling media.

Motivated by these challenges, this work will develop a fundamental insight into the feasibility of immersive cooling of LIBs using dielectric fluids including commercially available single and dualphase fluids but extending out to the investigation of more proprietary solutions currently being developed by Shell. This will be achieved by first developing a 3D thermally coupled electrochemical model of a LIB in COMSOL multi-physics to predict the heat generation characteristics as well as the performance and lifetime implications. In large form factor and multi-cell battery packs, commonly found in automotive battery packs, the heat generation can be high heterogeneous and it is critical to understand this. The insights from this project will help Shell develop improved E-fluids for the growing EV industry and add to academic knowledge around the use of single/multi-phase dielectric fluids for immerson cooling of LIBs.

Start Date: October 2019

Researcher: Bastien Bolle

Supervisor: Dr Janet Wong, Prof. Pavlos Aleiferis

Sponsor: Shell

Summary

The aim of the project is to investigate the flow of lubricants inside internal combustion engines.

Researcher: Dr Li Shen

Supervisor: Professor Daniele Dini, Dr Tom Reddyhoff

Sponsor: EPSRC, Shell, PCS Instruments, Ab InBev, PespsiCo

Summary

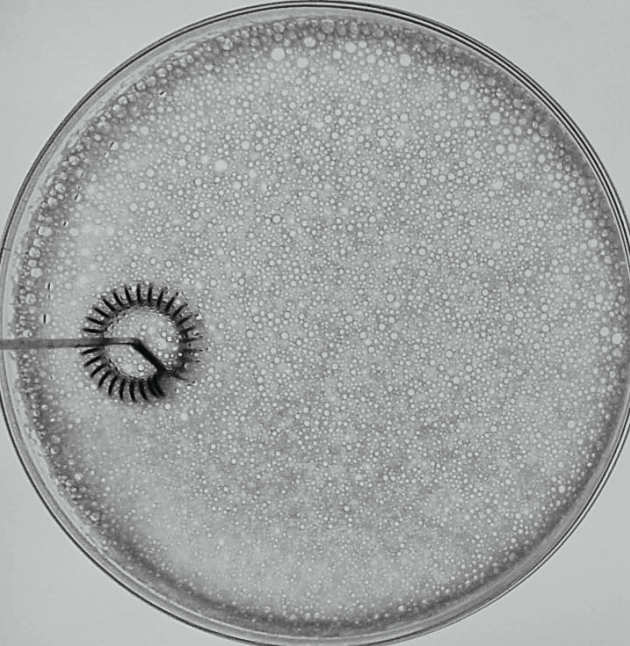

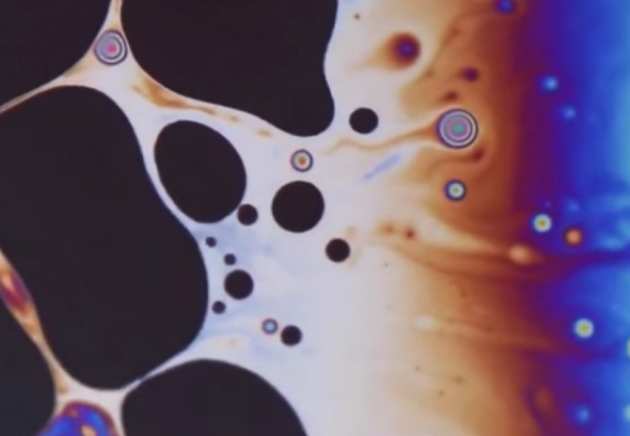

This project is an EPSRC Impact Acceleration Account (IAA) entitled “Machine-Learning Pattern Recognition Prototype for liquid foams”. The IAA grant supports the development of a potentially marketable project to create impact away from a strictly academic setting. The project aims to develop a foaming rig and a Machine-Learning analysis algorithm that will enable a consistent quantitative analysis of the foaming process in beverages and oil lubricants.

Shell technical stakeholder(s): Dr Michael Parkes

Supervisor(s): Dr Billy Wu

PhD Student: Anna Tomaszewska

Overview & Objectives: Electric vehicles (EVs) are poised to transform future molibility. This project will improve understanding the impact on battrey life of fast and ultra-fast EV charging profiles as well as 'charge while at rest' for grid balancing. Important variables include charge post power, battery chemsitry, cell architecture, and battery management systems. A combination of experiments and models will be used to facilitate optimised battery charging and discharging profiles for EVs.

Start Date: October 2018

Researcher: Amran Mohamed

Supervisor: Dr Janet Wong, Dr Luca di Mare (Oxford), Dr James P. Ewen

Sponsor: EPSRC, Shell (Science and Solutions for a Changing Planet DTP)

Summary

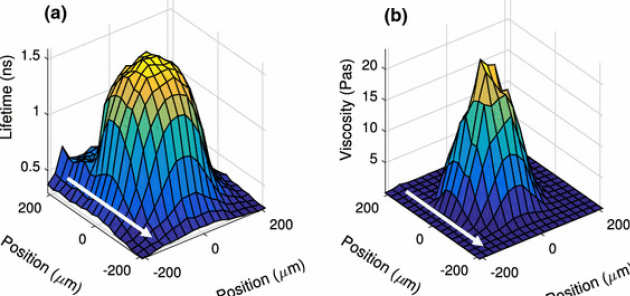

This project will use computer simulations to investigate the effect of VM molecular architectures on their stability and behaviour in lubricants in ranges of temperature, shear rates, and contact surfaces encountered in EV. Dissipative particle dynamics (DPD) simulations will be used. DPD method is a coarse grain method that allows simulations to be conducted in length scale and time scale that are close to those encountered in tribological contacts. The goal is to establish relationship among molecular architecture of additives, their stability and effectiveness. The knowledge can that be used to guide VM design for EV lubricants.

Researcher: Mao Ueda

Supervisor: Professor Hugh Spikes

Sponsor: Shell

Summary

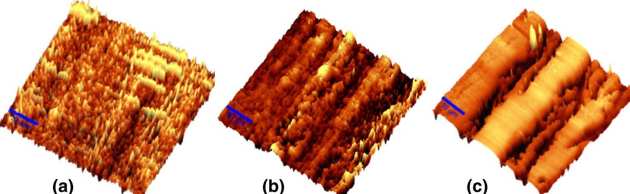

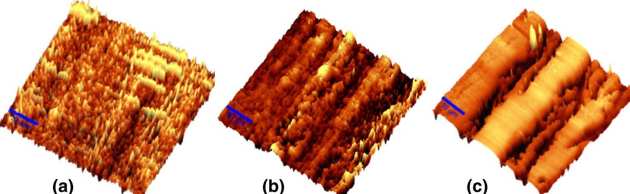

Zinc dialkyl dithiophosphate (ZDDP) is widely used as an anti-wear additive in engine oils. The tribofilms formed by ZDDP have been extensively investigated using friction and wear tests as well as surface analysis. However, the influence of ZDDP film properties on film durability and ultimately tribological performance remains unclear. The aim of this project is to uncover these relationships, as well as to investigate the effect of co-additives on ZDDP performance.

Shell technical stakeholder(s): Dr Neal Morgan

Supervisor(s): Dr Phillipa Cann, Dr Marc Masen

PhD Student: Rory McAllister

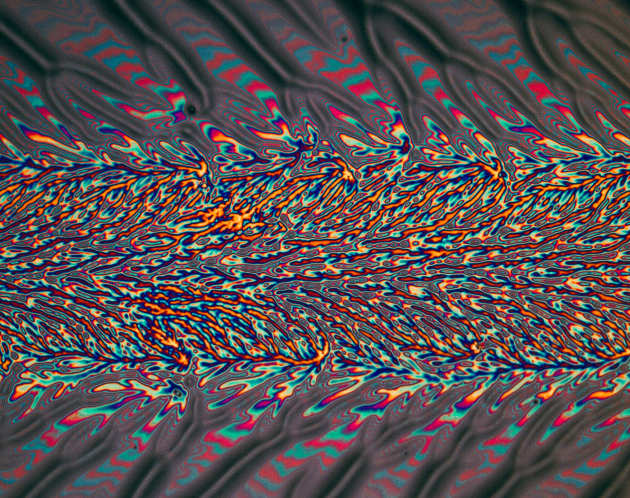

Overview & Objectives: Electrification of the automotive sector is putting even more emphasis on low-friction bearing lubricants, and the burgeoning battery market has driven up the price of lithium, a raw material in >70% of lubricating greases. There is, therefore, a need to replace the standard lithium grease thickener with a cheaper, equally effective alternative.

This project aims to investigate the performance of novel calcium complex grease formulations provided by Shell. Rolling contact tests will be performed with both lubricant degradation and inlet starvation controlled to emulate realistic bearing conditions. Techniques such as infrared spectroscopy will be used to analyse the rolled tracks in order to understand the mechanisms of grease lubrication.

Start Date: October 2017

Researcher: Eliane Gendreau

Supervisor: Dr Janet Wong, Professor Hugh Spikes

Summary

Viscosity modifiers are polymers added to lubricants to control viscosity. Effective viscosity modifiers are crucial in the automotive industry to facilitate the use of base oils with lower viscosity which can reduce hydrodynamic losses and thus increase fuel efficiency. The aim of the project is to investigate how the architecture of polymeric viscosity modifiers affects lubricant rheology. Techniques such as fluorescence spectroscopy will be used to study the effect of polymer architecture on thier temperature and shear responses inside hydrodynamic contacts.

Recent Projects

- Fuel-Delivered Friction Modifiers and Their Impact on Friction and Wear

- Fuel-Lubricant Interactions in the Combustion Chamber

- Influence of Fuel and Lubricant Additives on Friction and Wear in Engines

- Mechanochemical Behaviour of ZDDP

- Modelling Lubricant and Lubricant Additive Behaviour using Molecular Dynamics Simulations

- Modelling the Dynamics of Foaming & Antifoaming

- Negating the Effects of Soot on the Wear Properties of Engine Oil

- The Effect of Shear Stress on Lubricant Behaviour

Shell technical stakeholder(s): Dr Joe Russo

Shell technical stakeholder(s): Dr Joe Russo

Imperial supervisor(s): Professor Hugh Spikes

PhD student: Joanna Dawczyk

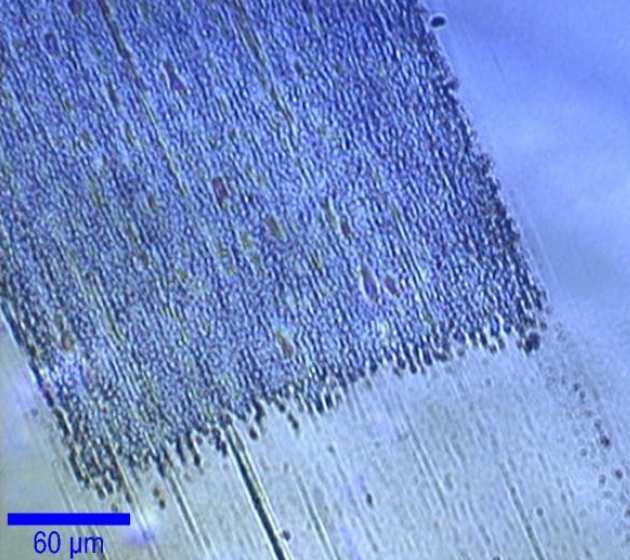

Overview & Objectives: Zinc dialkyldithiophosphates (ZDDPs) have been used as anti-wear additives for over 70 years. They are considered as the most efficient anti-wear additives. The tribofilm generated by the ZDDP is characterized by high boundary friction and it is known that organic friction modifiers can reduce this friction. Since both types of additives are employed together it is necessary to understand both the mechanism of the tribofilm formation and the mutual interaction between these additives. The scope of this PhD project is to study the interaction between the anti-wear film (generated by various types of ZDDP additives) and friction modifiers through the use of a range of lab analytical techniques including:

- Mini Traction Machine (MTM)

- Spacer Layer Imaging Method (SLIM)

- Atomic Force Microscopy (AFM)

- Focus Ion Beam Microscopy (FIB) followed by Ion Beam Erosion

- Scanning Auger Microscopy (SAM) followed by Ion Beam Erosion

- Scanning Electron Microscopy (SEM) followed by Ion Beam Erosion

- C13 Nuclear Magnetic Resonance (NMR) to determine the structure of Zinc/friction modifier complex

Start date: March 2014

Shell technical stakeholder(s): Dr Neal Morgan, Dr Renate Utiz

Shell technical stakeholder(s): Dr Neal Morgan, Dr Renate Utiz

Imperial supervisor(s): Dr Janet Wong, Professor Yannis Hardalupas, Professor Alex Taylor

PhD student: Jon Dench

Overview & Objectives: The primary aim of this PhD is to develop a method to implement fluorescence spectroscopy, to a gasoline direct injection engine (GDI), to study the composition of the fuel and lubrication mixture in moving ring-pack area. This technique provides an excellent opportunity to determine not only the chemical properties of this mixture but possibly also its temperature and viscosity. In addition, the measurement of the liquid mixture film thickness is possible. Access will be made to the liner using optical fibres in a metal engine, thus ensuring typical engine operating conditions are achieved. Measurements with the fluorescence technique may be complimented with visualisation of the fuel spray in order to understand the physical mechanisms that determine the fuel-lubricant mixture composition on the liner.

Start date: September 2014

Shell technical stakeholder(s): Dr Neal Morgan

Imperial supervisor(s): Professor Hugh Spikes

PhD student: Dr Jie Zhang (Jason)

Overview & Objectives:

It has recently been shown that tribofilm formation by the widely-used antiwear additive zinc dialkyl dithiophosphate (ZDDP) is driven by the applied shear stress present in rubbing contacts rather than by the energy dissipated in these contacts. This means that ZDDP reaction results from the stretching and breaking of molecular bonds under stress, i.e. mechanochemistry; an insight that enables relationships between molecular structure and reactivity to be developed. This project studies the impact of applied shear stress on ZDDP film formation under both full film and boundary lubrication conditions to support the principle that ZDDP reaction is controlled by mechanochemistry.

Start date: March 2017

Shell technical stakeholder(s): Dr Neal Morgan, Dr Foram Thakkar

Shell technical stakeholder(s): Dr Neal Morgan, Dr Foram Thakkar

Imperial supervisor(s): Professor Daniele Dini, Professor David Heyes, Professor Hugh Spikes

PhD student: James Ewen

Overview & Objectives: The aim of this project is to utilise molecular dynamics simulations to investigate the friction and flow behaviour of a range of lubricant and additve molecules. Modelling frameworks will be developed which can predict performance of a lubricant with sufficient accuracy to; screen many possible lubricant formulations and, once promising candidates are identified, obviate the need for expensive physical testing. Ultimately, the computer simulation techniques developed could be used to accelerate future lubricant development; yielding more varied, effective, formulations.

Start date: September 2014

Shell technical stakeholder(s): Dr Neal Morgan

Shell technical stakeholder(s): Dr Neal Morgan

Imperial supervisor(s): Professor Daniele Dini, Professor Berent van Wachem

PhD student: Li Shen

Overview & Objectives: Foam dynamics can be summarised into four distinct stages, its formation, drainage, coarsening and eventual rupture. The aim of this project is to understand:

- The time-dependent dynamics of the foam structure subject to non-linear liquid drainage, rupture and the consequent structure rearrangement using multiphase numerical simulations

- The physical mechanisms involved in the formation of a large 3-dimensional foam structure due to rising bubbles (this comes from the industrial problem of foaming in lubricants)

- The coarsening phase of the foam structure exhibiting local fractal behaviour and macroscopic polyhedral packing (Weaire-Phelan structure) using both kinetic and topological models possibly leading to new theories and/or visualisations.

Start date: September 2014

Shell technical stakeholder(s): Mark Southby, Dr Sergio de Rooy

Imperial supervisor(s): Professor Hugh Spikes

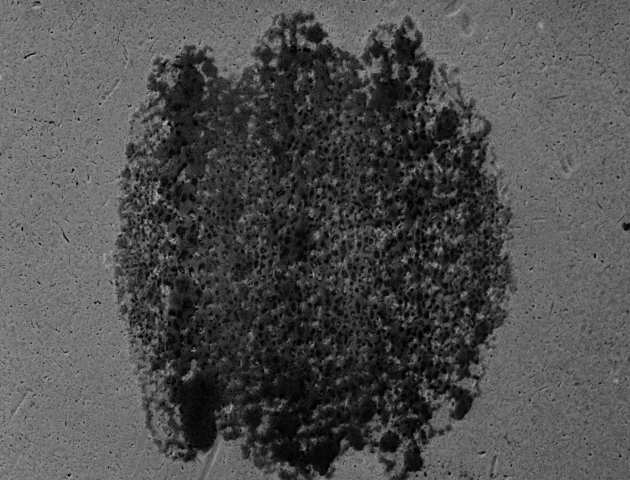

PhD student: Artemis Kontou

Overview & Objectives: Soot accumulation in diesel engine oils and more recently in gasoline engine oils can increase the rate of wear in certain engine components. As such this represents an important issue for vehicle manufacturers and lubricant companies to tackle but there are many conflicting theories and mechanisms suggested as to why soot increases the wear rate and how different additive combinations reduce it. The main aim of this PhD project is to study the influence of anti-wear additives and dispersants on soot-induced wear.

Start date: March 2014

Shell technical stakeholder(s): Dr Neal Morgan

Imperial supervisor(s): Dr Janet Wong, Professor Hugh Spikes

PhD student: Stephen Jeffreys

Overview & Objectives:

The aim of the project is to investigate the effect of shear stress on lubricant behaviour, particularly in high-pressure high-shear environments such as those found in elastohydrodynamic (EHD) contacts. Here it is critical to gain an understanding of the rheological properties at a molecular level, considering the local structure of the lubricant. Given the severity of operating conditions lubricants can reveal unusual phenomena where the Newtonian assumption may be inadequate. An inaccurate description of the flow limits our understanding of lubricant rheology which affects the ability to theorize novel ways of controlling friction. This impacts the overall goal to manipulate the tribological performance of engineering systems and improve efficiency.

Start date: September 2016