Understanding the Role of Interfaces and Local Residual Stresses on the Failure of Polycrystalline Metal-Ceramic Composites

Name: Giorgio Sernicola

Supervisors: Dr Finn Giuliani and Dr T. Ben Britton.

Sponsor: Element Six

Opening ceramics up to a wider range of applications necessitates us understanding and improving their fracture properties. This will enable increased exploitation of ceramics in applications such as space, deep well drilling and other extreme environments, where their high temperature stability, high hardness and high strength are required.

In the last three decades, improvements in fracture performance have been through developing new understanding of toughening mechanisms, typically involving microstructure control that focuses on crack deflection at grain boundaries and interfaces. Typically these improvements are difficult to engineer, as changing microstructural processing (e.g. through heat treatment / chemistry or powder processing) does not result in a one-to-one correlation with performance, as the influence of microstructure on crack path is varied and complex. We wish therefore to use and improve on recent developments of characterisation at the micro-scale to improve our understanding of performance at the macro-scale.

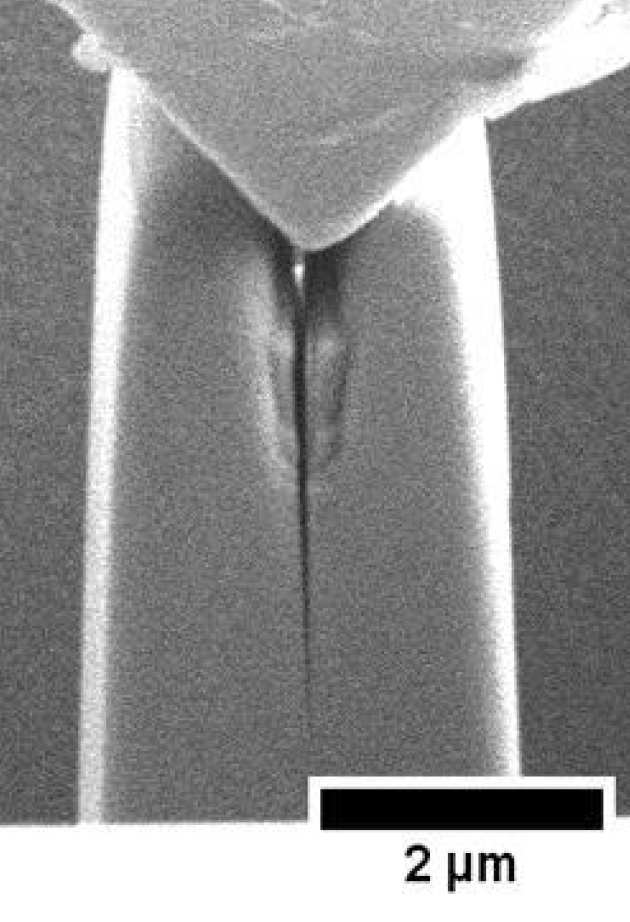

To investigate the fracture properties of individual features (i.e. individual crystallographic planes, individual grain boundaries or interfaces), we have developed an innovative fracture testing method. This approach is based on the double cantilever wedging to measure the fracture energy evolution with crack length during stable fracture and was successfully applied at the micro-scale inside a SEM (Fig. 1). This method enables direct view of the crack growth in our sample and direct measurement of the energy absorbed during fracture, without use of load-displacement data. This is afforded through the generation of a new stable geometry test, combined with an in-situ testing and image based analysis strategy that affords direct correlation of stable opening of a crack with the energy released in the test sample.

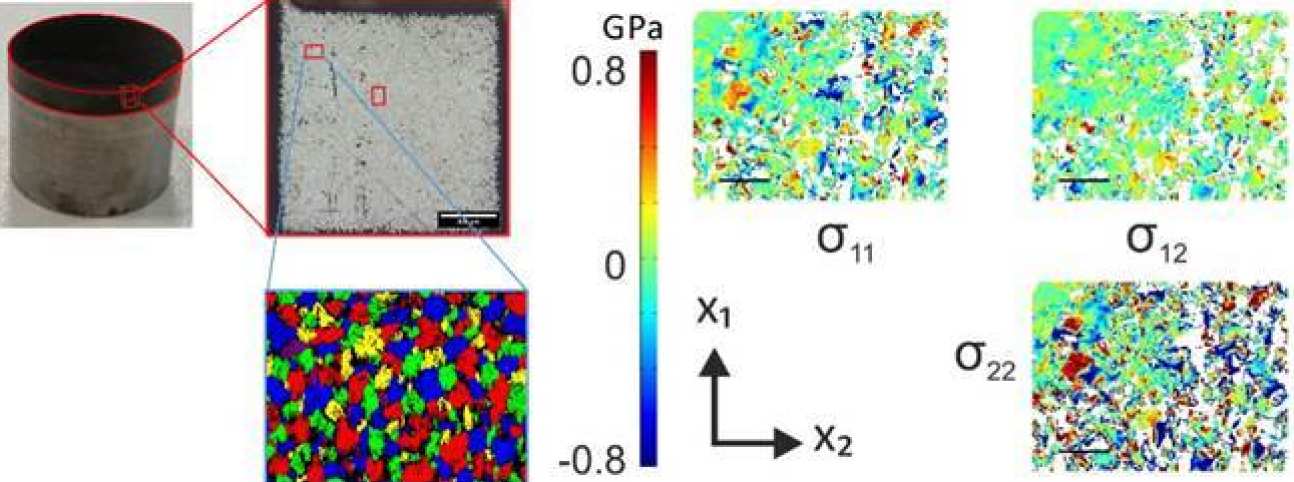

In addition to these precise tests, we have targeted characterisation at understanding how microstructure influences crack paths in polycrystalline metal-ceramic composites. Our focus has been on using high angular resolution EBDS combined with microindentation, to focus on how the local gradient of residual stresses (Fig. 2) due to thermal expansion mismatches change during an indentation based fracture test.

Exploitation of these novel techniques allows us to gather new insights on the mechanical properties of advanced ceramics that can usher in a new way of engineering the microstructure to obtain tougher ceramics.

Figure 1. In situ wedging of a DCB of SiC

Figure 2. In plane stress gradient maps measured via HR-EBSD on a polycrystalline diamond sample