Composites and material innovation

Overview

The development of high fidelity modelling tools in the Aeronautics Department is helping engineers to design more efficient composite structures and to avoid the high cost of physical prototype testing. Much of our modelling research is conducted with finite element (FE) codes often incorporating bespoke algorithms to enable the complex failure processes in fibre reinforced composites to be accurately predicted.

Recent FE work has included a focus on incorporating thickness dependence of the translaminar fracture process and its application to notched tension failure, a parametric study of the stresses in a composite bolted joint, enrichment strategies for improved delamination modelling, and a tri-linear cohesive law for specimen independent prediction of intralaminar R-curves at quasi-static loading speeds.

For impact and ballistic loading FE-based techniques to capture progressive failure including strain rate effects have been developed and are being applied to develop improved armour. Mesh-less computational methods hold particular advantages for composites with complex architectures and one technique developed at Imperial has shown good performance in predicting the stiffness of 3-D woven composites.

Analytical modelling has also been used to address a range of complex problems including predicting the trajectory of runway stones thrown up by the wheels of an aircraft during take-off and landing, the response of sandwich beams to shock loading and the mechanics of failure development in re-cycled composites. Modelling, both FE and analytical, is also being used extensively within our programme grant HiPerDuCT to help evaluate potential mechanisms for incorporating ductility into high performance composites.

Facilities

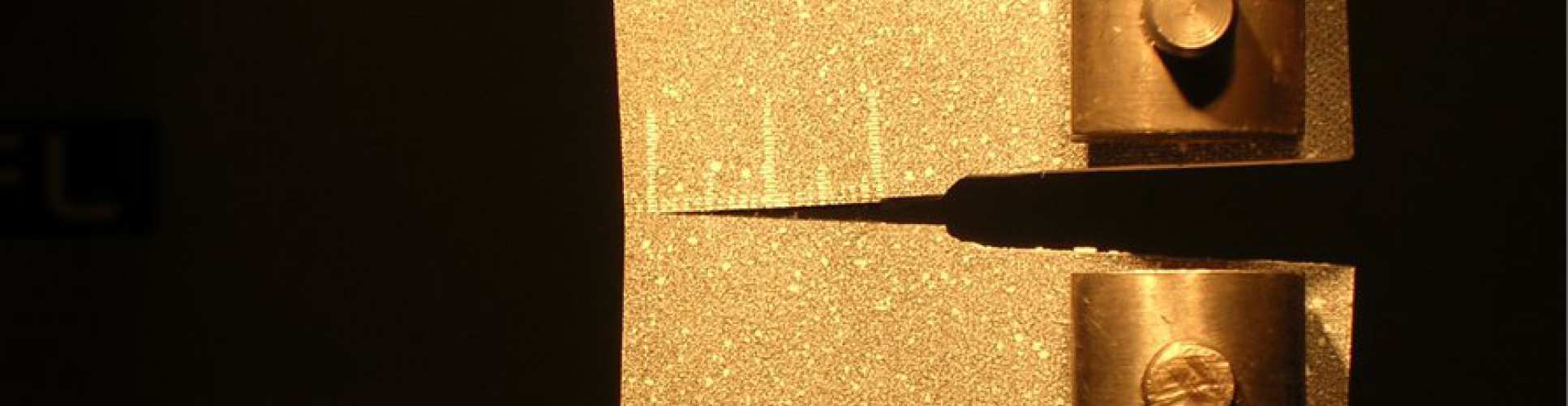

Flight area equipped with 3D flight tracker system, high precision laser micro machining system, 3D printer, 3 mechanical and fatigue testing machines, low velocity impact facility, high velocity gas guns, SEM and micro braiding facilities.

Funding

Major recent grants include an EPSRC-DSTL award (£1.2 M, Iannucci and Robinson) to increase the survivability of structures to impact and blast, MYMOSA, an EU grant £1.8 M, to improve the safety of motorcyclists, and the UK’s only EPSRC programme grant in Composites (HiPerDuCT, £6.5 M, Robinson).

The department also has additional funding totalling £x M from a range of sources including EPSRC, EU, DSTL, Airbus and MBDA. Iannucci is a Dstl / Royal Academy of Engineering Research Professor in multi-scale armour design.

Staff

Professor Ferri Aliabadi

Professor Ferri Aliabadi

Chair in Aerostructures

Professor Emile S Greenhalgh

Professor Emile S Greenhalgh

Professor of Composite Materials

Professor Rafael Palacios

Professor Rafael Palacios

Head of the Department of Aeronautics

Professor Silvestre T Pinho

Professor Silvestre T Pinho

Professor in the Mechanics of Composites

Professor Paul Robinson

Professor Paul Robinson

Professor of Mechanics of Composites

Professor Zahra Sharif Khodaei

Professor Zahra Sharif Khodaei

Professor in AerospaceStructural Durability&HealthMonitoring

Dr Vito Tagarielli

Dr Vito Tagarielli

Associate Professor in Mechanics of Solids

Multifunctional materials, smart and micro air vehicles

Overview

The development of composites which can store electrical energy as well as acting as a structural material. Such materials could eventually result in lighter air vehicles by reducing the need for other electricity storage systems and could also be adopted in cars, laptops, mobile phones and other applications containing separate structure and electric power systems. A smart composites structural concept is being developed in which advancing cracks can be diverted and arrested, and any matrix damage can be repaired by an embedded self-healing capability.

In another multifunctional composite being developed, the flexural stiffness can be significantly reduced on demand and this material may find applications in adaptive and deployable structures. Other means of achieving adaptive shape structural configurations are also being explored and developed including bi-stable, pseudo bi-stable and multi-stable structures.

Beyond material and structural aspects, research is developing modelling tools to enable the design of active noise suppression techniques to reduce the perception of cabin noise in an aircraft. The research in micro-air vehicles is a new and exciting development for the Department of Aeronautics. Initial research into miniaturised mechanisms and structural manufacturing for jumping insect like robots has established important foundations for our future micro-air vehicle research programme.

Facilities

Flight area equipped with 3D flight tracker system, high precision laser micro machining system, 3D printer, 3 mechanical and fatigue testing machines, low velocity impact facility, high velocity gas guns, SEM and micro braiding facilities.

Funding

SEAT (Smart Technologies for stress Free AiR Travel) an EU project examining techniques for improving aircraft passenger comfort (£1.4 M), SARISTU (Smart Intelligent Aircraft Structures) an EU project led by Airbus investigating structural health monitoring techniques (£761K), and STORAGE (Composite Structural Power Storage for Hybrid Vehicles) an EU project for the development with structural composite supercapacitors (£ 1.7 M). Other funding is addressing the development of composite structures with the ability to arrest cracks and self-repair the damage, the development of composite materials with controllable stiffness, and the design and evaluation of adaptive structure configurations.

Staff

Aliabadi, Greenhalgh, Kovac, Robinson, Santer, Panesar, Li, Sharif Khodaei

Professor Ferri Aliabadi

Professor Ferri Aliabadi

Chair in Aerostructures

Professor Emile S Greenhalgh

Professor Emile S Greenhalgh

Professor of Composite Materials

Professor Mirko Kovac

Professor Mirko Kovac

Honorary Professor

Professor Paul Robinson

Professor Paul Robinson

Professor of Mechanics of Composites

Professor Matthew Santer

Professor Matthew Santer

Professor of Aerospace Structures

Professor Zahra Sharif Khodaei

Professor Zahra Sharif Khodaei

Professor in AerospaceStructural Durability&HealthMonitoring