ASCENT (Advanced Solid Cycles with Efficient Novel Technologies)

Matthew Boot-Handford

Supervisor: Professor Paul Fennell

Funding: EU FP7 Grant Agreement

ASCENT (Advanced Solid Cycles with Efficient Novel Technologies) is a 9.2 M € research project funded by the EU under the FP7 grant agreement. ASCENT is a collaborative research project involving Academic and public research institutes as well as small and medium enterprises (SMEs) across 7 different European countries. The project was started in February 2014 and runs for a total of four years.

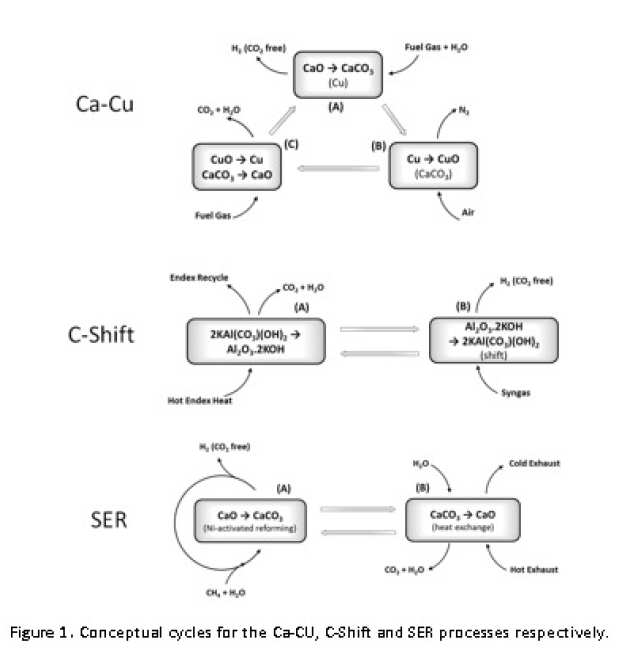

ASCENT focuses on the development of three related high-temperature solid-looping pre-combustion CO2 capture processes for the production of H2 and efficient decarbonised power from natural gas or syn-gas. Capturing CO2 at elevated temperatures (> 300˚C) provides an opportunity for more efficient heat integration options that are not available when the separation is performed at lower temperatures. The three technologies include: (i) an integrated calcium/copper looping cycle; (ii) a sorbent enhanced reforming (SER) process for the production of H2 to supply a solid oxide fuel cell (SOFC) with the waste heat used to drive the endothermic sorbent calcination reaction; and (iii) the novel carbonated-shift (CSHIFT) process. ASCENT technologies are designed such that endothermic and exothermic heat requirements of the reforming, shift and sorbent regeneration reactions are matched in an integrated in-situ approach. As part of ASCENT, Imperial is working alongside partners at ECN (Netherlands), Sintef (Norway), Calix Limited (Australia/UK) and Polimi (Italy) on the development of the novel Carbonated-Shift (C-SHIFT) process.

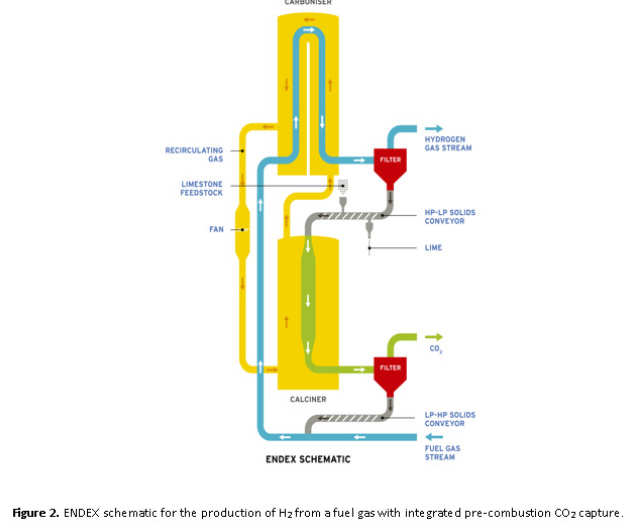

C-SHIFT is the term coined as part of ASCENT to describe a high-temperature sorbent enhanced water-gas shift (SEWGS) process for combined CO2 capture and H2 production from syngas using the highly innovative ENDEX reactor technology currently being developed by Calix Limited (fig. 2). The ENDEX (endothermic-exothermic) reactor concept involves using the heat released during the exothermic sorbent carbonation reaction to provide the heat necessary to drive the endothermic desorption reaction. This is possible by elevating the carbonator pressure and running the sorbent regenerator at atmospheric or sub-atmospheric pressure such that carbonation can be carried out at a higher temperature than desorption. To date, ENDEX reactor development for pre-combustion CO2 capture has almost exclusively involved calcium oxide as the CO2 sorbent. However, engineering challenges and safety considerations as well as sorbent capacity degradation issues associated with the high temperature operation required for calcium looping (650-1000 ˚C) has provoked interest in the application of alternative CO2 sorbents that operate at more moderate temperatures (300-800 ˚C) such as alkali-carbonate promoted mixed metal oxides derived from hydrotalcites, magnesium oxide and promoted aluminas.

Imperial is currently contributing to the ASCENT project through the development of simple, scalable and highly reactive alkali-promoted hydrotalcite and high surface are magnesium oxide materials. Successfully prepared materials are then tested at industrially relevant conditions in a highly innovative spouted fluidised bed reactor that can be operated at pressures up to 30 bar, temperatures up to 950 ˚C and with high concentrations of steam (fig.3). The reactor allows for the determination of carbonation kinetic and capacity studies providing key performance indicators necessary for the development of a new C-SHIFT ENDEX Cycle model that will in turn feed into a high level systems model. The ultimate objective of ASCENT is to test promising sorbents at industrially relevant conditions, providing a robust proof-of-principle for the process.